At its core, a volume honey filling machine ensures accuracy by using a precisely controlled mechanism to dispense a pre-set, measured amount of honey into a container. This process is governed by a combination of a filling system, sensors, and actuators that execute the command with high repeatability, often achieving a filling accuracy of around ±0.5%. This precision minimizes product waste and ensures each package meets regulatory standards.

The key to understanding filling accuracy is realizing it's not about one single technology. It’s about choosing the right mechanism—most often a piston filler—that can controllably displace a viscous liquid like honey, balancing the need for precision against factors like speed and cost.

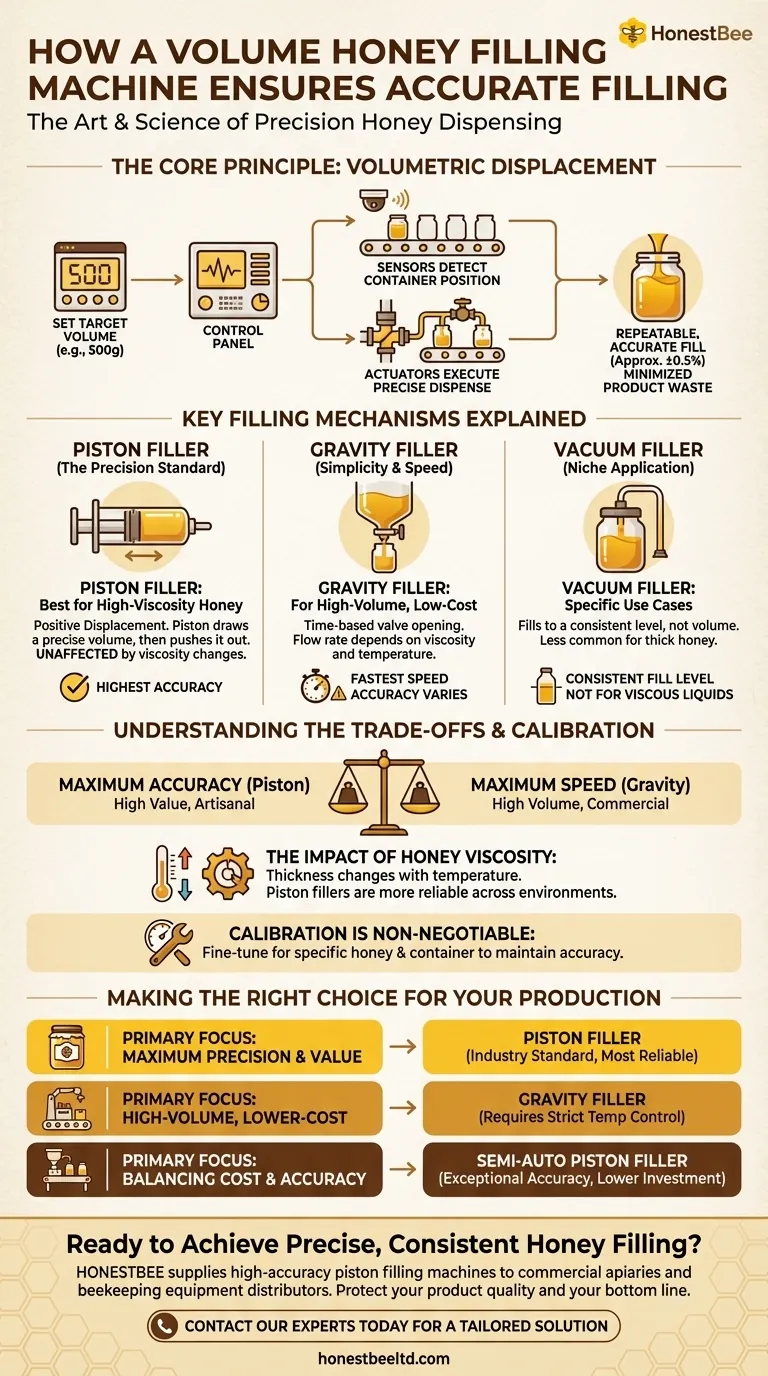

The Core Principle: Volumetric Displacement

A honey filling machine doesn't just "pour" honey. It operates on the principle of volumetric displacement, where a specific volume of product is isolated and then dispensed.

Setting the Target Volume

The process begins when an operator inputs the desired fill volume (e.g., 500g or 12oz) into the machine's control system. This digital command becomes the target for every fill cycle.

The Control System: Sensors and Actuators

Once the volume is set, the machine uses sensors to detect the container's position. Actuators and valves then control the flow of honey from a hopper into the filling mechanism and finally through the nozzle, starting and stopping the flow with precision to match the target volume.

Key Filling Mechanisms Explained

While the principle is the same, different machines use different mechanisms to achieve it. The choice of mechanism is critical and depends heavily on the properties of honey.

The Piston Filler: Precision for Viscosity

The piston filler is the most common and effective method for honey. It works like a large syringe: a piston retracts inside a cylinder, drawing a precise volume of honey from the hopper. The piston then pushes forward, dispensing that exact amount into the container.

This method of positive displacement is ideal for thick, viscous liquids because it is largely unaffected by changes in honey temperature or viscosity, ensuring consistent and accurate fills every time.

The Gravity Filler: Simplicity and Speed

A gravity filler works by opening a valve for a pre-set amount of time, allowing honey to flow from an overhead tank into the container using the force of gravity.

While simpler and often faster, this method's accuracy can be compromised by changes in honey's viscosity. If the honey gets colder and thicker, less will flow in the allotted time, leading to under-filled jars.

The Vacuum Filler: A Niche Application

A vacuum filler creates a vacuum in the bottle, which then draws the honey in until it reaches the desired level. This is less common for pure, thick honey and is typically used for lower-viscosity liquids or specific container types where a consistent fill level is more important than a precise volume.

Understanding the Trade-offs

Selecting a filling machine involves balancing competing priorities. Accuracy is paramount, but it must be weighed against other operational factors.

Accuracy vs. Speed

Piston fillers offer the highest accuracy but may have a slower cycle time compared to multi-nozzle gravity fillers. For high-value artisanal honey, precision is non-negotiable. For high-volume commercial operations, a slight trade-off for speed might be considered, though it risks inconsistency.

The Impact of Honey Viscosity

Honey's thickness changes with temperature. This is the primary weakness of time-based gravity fillers. A piston filler's mechanical action makes it far more reliable across different production environments and honey varieties.

Calibration is Non-Negotiable

No machine is perfectly accurate out of the box. Calibration is a critical step where the machine is fine-tuned for the specific honey type, container size, and target volume. This process must be repeated whenever the product or packaging changes to maintain accuracy.

Making the Right Choice for Your Production

Your ideal machine depends entirely on your primary goal. Use these guidelines to inform your decision.

- If your primary focus is maximum precision and product value: A piston filler is the industry standard and the most reliable choice for ensuring every jar is filled accurately.

- If your primary focus is high-volume, lower-cost production: A gravity filler could be considered, but you must have strict temperature controls in place to manage honey viscosity.

- If your primary focus is balancing cost and accuracy for a small batch operation: A semi-automatic, single-head piston filler provides exceptional accuracy without the investment of a fully automated line.

Understanding these filling mechanisms allows you to select a machine that not only fills jars but also protects your product's quality and your bottom line.

Summary Table:

| Filling Mechanism | Best For | Key Advantage | Accuracy Consideration |

|---|---|---|---|

| Piston Filler | High-Viscosity Honey | Positive displacement; unaffected by viscosity changes | Highest accuracy (±0.5%) |

| Gravity Filler | High-Volume, Low-Cost | Simplicity and speed | Accuracy can vary with honey temperature/viscosity |

| Vacuum Filler | Specific Applications | Consistent fill level | Less common for pure, thick honey |

Ready to Achieve Precise, Consistent Honey Filling?

Choosing the right filling machine is critical to protecting your product quality and your bottom line. HONESTBEE supplies beekeeping supplies and equipment, including high-accuracy piston filling machines, to commercial apiaries and beekeeping equipment distributors.

Let us help you select the perfect equipment for your production goals. Contact our experts today to discuss your specific needs and get a tailored solution that ensures every jar is filled accurately.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- What output-related factors should be considered before buying a honey stick machine? Optimize Your Production Today

- What role do automated honey-filling machines play in commercial distribution? Scale Your Honey Export Business

- What advanced equipment is available for professional honey bottling? Optimize Your Production and Quality Control

- What are the steps involved in the working principle of a honey stick machine? Automate Your Honey Packaging

- What is the role of the piston pump in a honey stick machine? The Heart of Precise Honey Filling

- What is the best use case for gravity filling machines? Bottle Thin Liquids with Unmatched Simplicity

- What contribution does automated honey filling machinery make to the honey product supply chain? Scaling Global Success

- How do automated honey-filling machines contribute to the commercial honey processing chain? Scale Your Apiary Output