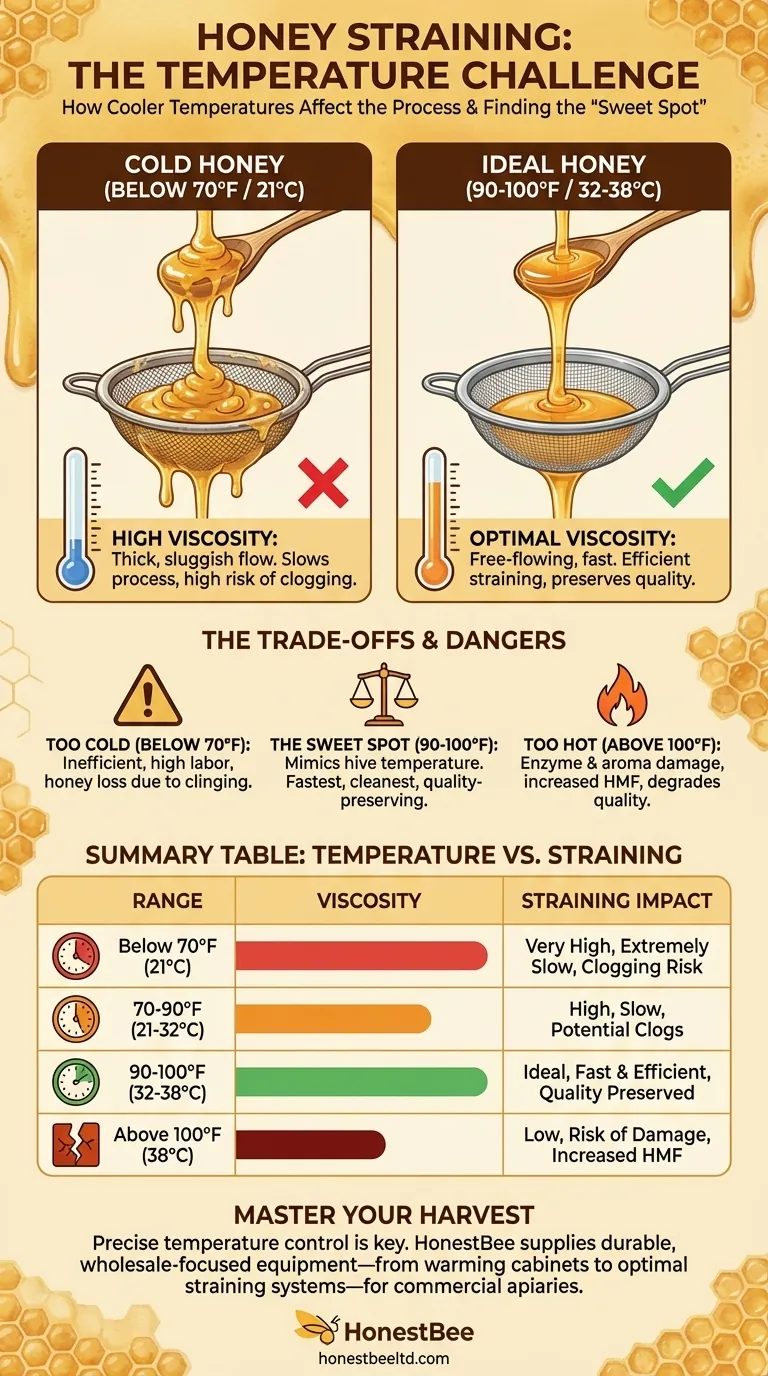

The short answer is: cooler temperatures significantly slow down the honey straining process. As honey cools, its viscosity increases, meaning it becomes much thicker and flows more sluggishly. This makes it difficult for the honey to pass through the fine mesh of a strainer, leading to longer processing times and potential clogs.

The core challenge of straining honey is a balancing act between efficiency and quality. While cooler honey is difficult to work with, applying excessive heat to make it flow faster will damage its delicate enzymes, aromas, and nutritional profile. The goal is to find the optimal temperature that allows for easy straining without compromising the honey's natural character.

The Physics of Honey: Why Temperature is Critical

To master honey processing, you must first understand its physical properties. Honey is a supersaturated sugar solution, and its behavior is highly dependent on temperature.

Understanding Viscosity

Viscosity is a measure of a fluid's resistance to flow. Think of the difference between pouring cold molasses and warm maple syrup.

Cold honey has high viscosity. The sugar molecules are less energetic and bind more tightly, making the liquid thick and resistant to movement. Warm honey has low viscosity, allowing it to flow freely.

The Problem with Cold Honey

When honey drops below 70°F (21°C), its viscosity increases dramatically. It becomes so thick that it struggles to pass through the small openings in a standard honey strainer.

This not only makes the process incredibly slow but can also cause "blinding," where the strainer's surface becomes completely clogged with wax particles and debris that are unable to pass through with the thick honey.

The Impact on Straining Efficiency

An inefficient straining process has several negative consequences. It requires constant supervision, increases labor time, and can lead to significant honey loss, as the thick liquid clings to equipment, uncapped frames, and the wax cappings themselves.

Understanding the Trade-offs: Heat, Speed, and Quality

The obvious solution to thick, cold honey is to heat it. However, this introduces a critical trade-off between speed and the very quality you are trying to preserve.

The Danger of Excessive Heat

Honey is a delicate biological product. Overheating, even for short periods, can cause irreversible damage.

Excessive heat destroys beneficial enzymes like diastase and invertase, degrades the subtle floral aromas, and can even alter the flavor. It also increases the level of HMF (hydroxymethylfurfural), a chemical compound used as an indicator of heat damage or old age in honey.

The Clogging Conundrum

Attempting to force cold, thick honey through a strainer is often counterproductive. The high pressure required to push it through can quickly clog the mesh with wax and pollen.

This forces you to stop and clean the strainer repeatedly, halting your workflow and adding to your processing time.

Finding the "Sweet Spot"

The ideal temperature for straining honey is between 90°F and 100°F (32-38°C). This range mimics the natural temperature inside a beehive.

At this gentle warmth, the honey's viscosity is low enough for it to flow easily through a strainer, but the temperature is not high enough to cause damage to its delicate components. This makes the entire process faster, cleaner, and more efficient.

Making the Right Choice for Your Goal

Your approach should be dictated by your equipment, timeline, and primary objective for the final product.

- If your primary focus is speed and efficiency: Gently warming your honey to the 90-100°F (32-38°C) range using a controlled warming cabinet or water bath is the most effective way to reduce straining time.

- If your primary focus is preserving "raw" status: You must strain the honey at room temperature (ideally above 70°F / 21°C) and accept that the process will be significantly slower and may require larger-mesh filters.

- If you are dealing with partially crystallized honey: Gentle warming is not just helpful, it is necessary to re-liquefy the sugar crystals before the honey can pass through any strainer at all.

Ultimately, managing temperature is the key to unlocking an efficient and high-quality honey harvest.

Summary Table:

| Temperature Range | Effect on Honey Viscosity | Impact on Straining Process |

|---|---|---|

| Below 70°F (21°C) | Very High (Very Thick) | Extremely slow, high risk of clogging, inefficient |

| 70-90°F (21-32°C) | High (Thick) | Slow, potential for clogs and honey loss |

| 90-100°F (32-38°C) | Ideal (Free-Flowing) | Fast, efficient, preserves quality |

| Above 100°F (38°C) | Low (Very Thin) | Risk of damaging enzymes, aromas, and increasing HMF |

Master Your Honey Harvest with the Right Equipment

Straining honey efficiently while protecting its delicate quality requires precise temperature control. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused supplies needed for a superior harvest—from warming cabinets to optimal straining systems.

Contact our experts today to discuss how our equipment solutions can streamline your processing, save you time, and protect the premium quality of your honey.

Visual Guide

Related Products

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- Why is the use of dry sieves and storage containers critical? Prevent Honey Fermentation and Spoilage

- How does the internal ventilation management of a beehive affect the efficiency of honey dehydration?

- Why is industrial-grade dehumidification equipment essential for producing commercial-standard honey? Expert Insights

- How does a honey dryer remove moisture from honey? Achieve Perfect Honey Stability with Controlled Drying

- What are some methods to prevent fermentation in high-moisture honey? Protect Your Honey's Quality and Value