At its core, a honey stick machine's filling station operates on a principle of precision and control. It uses a system of pumps and pistons to draw a specific, pre-set volume of honey from a holding tank and dispense it gradually and cleanly into the newly formed packaging tube.

The filling station is not just a dispenser; it is the heart of the machine's quality control. Its accuracy directly determines product consistency, profitability, and waste, making its precise operation critical to the entire production line.

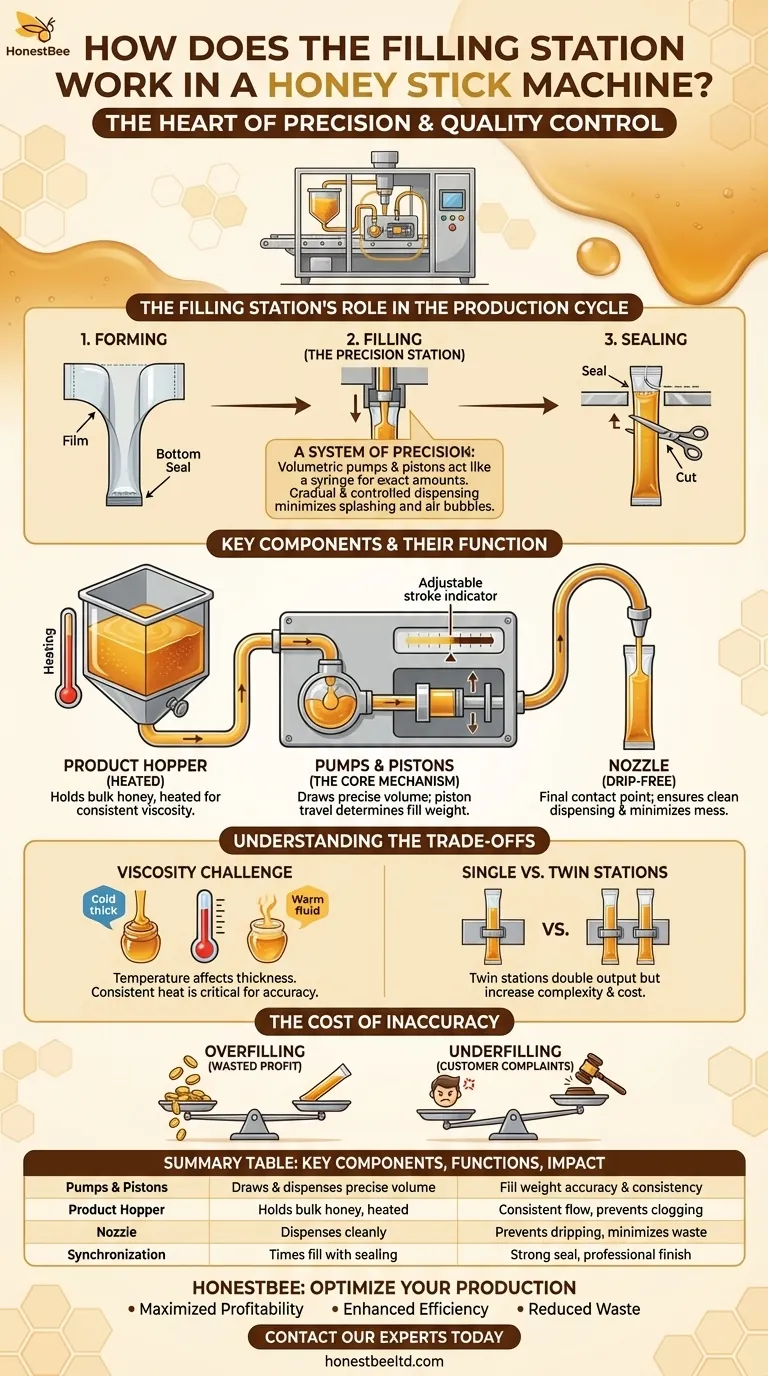

The Filling Station's Role in the Production Cycle

A honey stick is not filled in isolation. The filling action is a perfectly timed event in a larger, synchronized sequence of forming, filling, and sealing. Understanding this context is key to appreciating its function.

A System of Precision

The station is equipped with volumetric pumps and pistons. These components act like a syringe, pulling in an exact amount of honey on one stroke and pushing it out into the stick pack on the next.

This mechanical precision ensures that every stick contains the same amount of product, which is crucial for both regulatory compliance and customer satisfaction.

Gradual and Controlled Dispensing

The honey is dispensed gradually, not all at once. This prevents splashing, which could compromise the top seal, and minimizes the introduction of air bubbles into the stick.

A clean, controlled fill is essential for a strong, reliable seal and a professional-looking final product.

Synchronization with Sealing

The filling process occurs at a specific moment. It happens after the vertical seam and bottom horizontal seal have been created to form a pouch, but before the top of the stick is sealed shut.

The machine's central motor ensures this timing is flawless, with the filling piston firing in perfect harmony with the movement of the packaging film and the action of the sealing bars.

Key Components and Their Function

While the concept is straightforward, several components work together to achieve a perfect fill every time.

The Product Hopper

This is the reservoir that holds the bulk honey before it enters the filling system. In larger operations, these hoppers may be heated to keep the honey at a consistent viscosity for easier pumping.

Pumps and Pistons

This is the core mechanism. The pump draws honey from the hopper, and the piston's travel distance, which is adjustable, determines the exact volume for each stick. This is the primary point of calibration for fill weight.

The Nozzle

Attached to the piston system, the nozzle is the final point of contact. It is inserted briefly into the top of the formed stick pack to dispense the honey cleanly. High-quality machines use nozzles that prevent dripping between cycles to minimize mess and waste.

Understanding the Trade-offs

Choosing and operating a filling station involves balancing speed, precision, and complexity.

Single vs. Twin Filling Stations

A standard machine has one filling station. However, twin honey stick machines use two hoppers and two filling systems to fill two sticks simultaneously.

This dramatically increases production output but also adds mechanical complexity, a higher initial investment, and increased maintenance requirements.

The Challenge of Viscosity

Honey's thickness (viscosity) changes significantly with temperature. A colder, thicker honey is harder to pump accurately than a warmer, more fluid honey.

This means that maintaining a consistent temperature in the hopper and production environment is critical. Failing to manage viscosity can lead to inaccurate fills even on a perfectly calibrated machine.

The Cost of Inaccuracy

Even minor inaccuracies in the filling process have significant consequences. Overfilling wastes valuable product and cuts into profit margins with every stick produced. Underfilling can lead to customer complaints and potential legal issues regarding label weight.

Making the Right Choice for Your Goal

The filling station's configuration and operation should align directly with your production objectives.

- If your primary focus is maximizing output: A twin honey stick machine with two filling stations is the most effective solution for high-volume production lines.

- If your primary focus is product consistency: Prioritize a machine with high-quality pumps, precise piston calibration, and integrated hopper temperature controls to manage viscosity.

- If your primary focus is minimizing waste: Ensure your machine has drip-free nozzles and is precisely synchronized to avoid spills between the filling and sealing cycles.

Ultimately, mastering the filling station is central to achieving an efficient, profitable, and high-quality honey stick operation.

Summary Table:

| Key Component | Primary Function | Impact on Production |

|---|---|---|

| Pumps & Pistons | Draws and dispenses a precise volume of honey | Determines fill weight accuracy and consistency |

| Product Hopper | Holds bulk honey; often heated for viscosity control | Ensures consistent flow and prevents clogging |

| Nozzle | Dispenses honey cleanly into the stick pack | Prevents dripping and minimizes product waste |

| Synchronization | Times the fill with sealing actions | Ensures a strong seal and professional finish |

Ready to optimize your honey stick production line?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-performance honey stick machines engineered for precision filling. Our solutions deliver:

- Maximized Profitability: Precise volumetric control eliminates overfilling and underfilling.

- Enhanced Efficiency: Choose from single or twin filling stations to match your output goals.

- Reduced Waste: Drip-free nozzles and synchronized sealing ensure a clean, efficient process.

Let us help you achieve flawless product consistency and scale your operation. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What role do industrial-grade honey-filling machines play in apiary recovery? Boost Efficiency & Drive Profit.

- How do industrial honey filling and labeling machines scale the stingless bee industry? Transform Your Global Reach

- What are the technical advantages of using industrial-grade honey filling machines compared to manual filling processes?

- What technical advantages do automated honey-filling machines offer? Enhance Purity and Precision in Every Bottle

- Why is high-precision honey filling and packaging equipment critical in the industrial honey export process? Scale Now

- Why is high-performance honey filling and packaging machinery essential? Elevate Your Brand in International Markets

- What is the significance of using high-precision honey-filling machines? Boost Efficiency & Ensure Hygiene Standards

- What are the key advantages of automatic filling machines? Boost Speed, Accuracy & Scalability