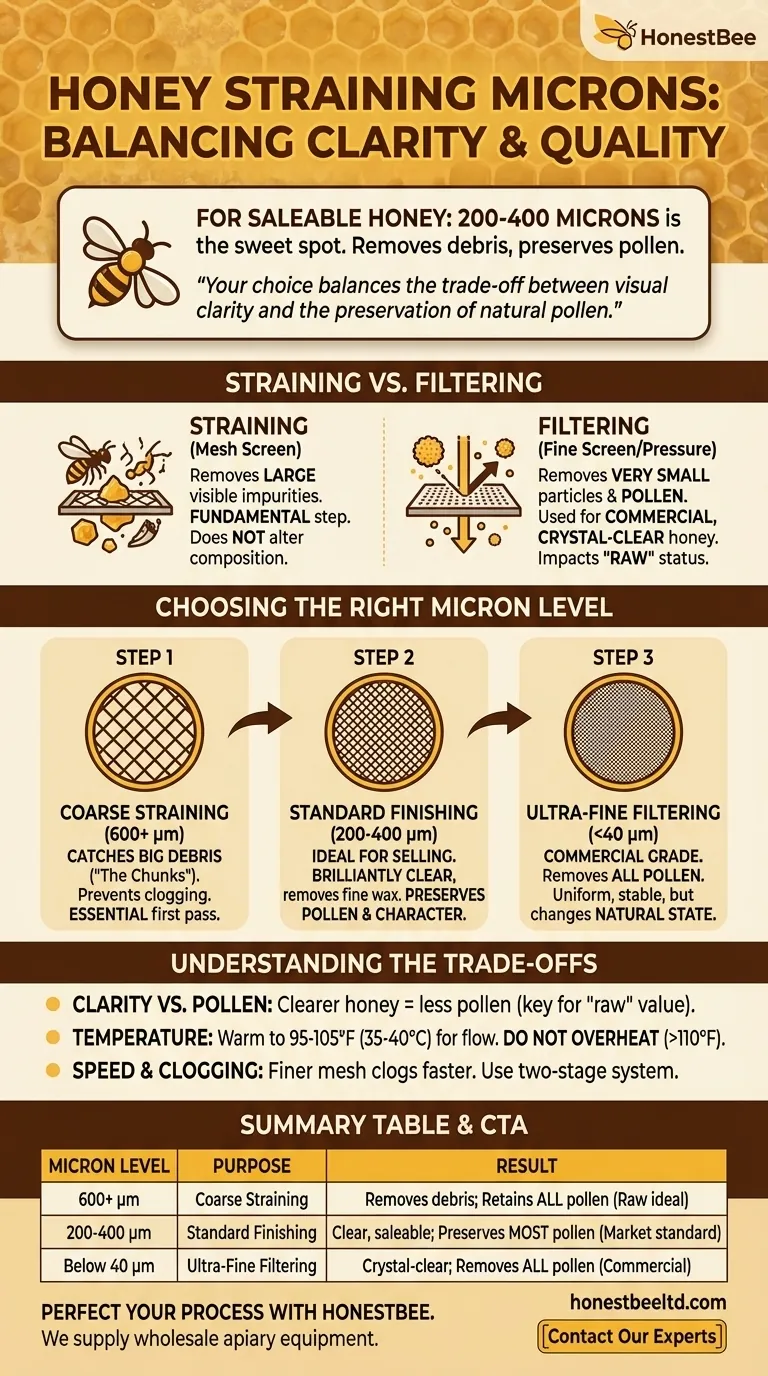

For straining honey, the most common and effective micron size for a clear, saleable product is between 200 and 400 microns. This level is fine enough to remove unwanted debris like wax particles and bee parts, resulting in visually appealing honey, while still coarse enough to allow beneficial pollen grains to pass through.

The question isn't about finding a single "correct" micron size, but understanding how different levels of straining and filtering define the final character of your honey. Your choice balances the trade-off between visual clarity and the preservation of natural pollen.

Straining vs. Filtering: A Critical Distinction

To make an informed choice, you must first understand the difference between straining and filtering. These terms are often used interchangeably, but they describe two very different processes with different outcomes.

What is Straining?

Straining involves passing honey through a mesh screen to remove large, visible impurities. This includes bits of wax, wood from the frames, and other debris from the hive.

This is considered a fundamental step for all honey processing. The goal is simply to clean the honey without fundamentally altering its composition.

What is Filtering?

Filtering is a more intensive process that uses much finer screens and often high pressure. The primary goal of filtering is to remove very small suspended particles, including most or all of the pollen grains.

This process is typically used for mass-market commercial honey to achieve a crystal-clear appearance and delay crystallization, but it removes elements that many consumers value.

The Impact on "Raw" Honey

The presence of pollen is a key marker for "raw" and local honey. Fine filtering, by removing this pollen, can mean the honey no longer meets the standard for being called "raw" in many markets. It also makes the honey's floral origin untraceable.

Choosing the Right Micron Level for Your Honey

Your goal for the final product directly dictates the micron level you should use. The process is often done in stages, moving from a coarse to a finer strain.

Step 1: Coarse Straining (600+ Microns)

This should always be your first pass after extraction. A 600-micron strainer is ideal for catching the big pieces of debris—what beekeepers call "the chunks."

This initial step prevents your finer strainers from clogging up immediately and is essential for an efficient workflow.

Step 2: Standard "Finishing" Strain (200-400 Microns)

This is the sweet spot for most small-scale beekeepers who want to sell their honey. A 200 or 400-micron strainer produces brilliantly clear honey that looks professional and clean.

This level removes fine wax particles and other small impurities but preserves the vast majority of the natural pollen, retaining the honey's character and nutritional benefits.

Ultra-Fine Filtering (Below 40 Microns)

This level is rarely used outside of large commercial packing plants. Screens between 1 and 40 microns will remove all pollen and other microscopic particles.

This process, often combined with pasteurization, is designed to create a uniform, highly stable product for the supermarket shelf. It fundamentally changes the honey from its natural state.

Understanding the Trade-offs

Choosing a straining method involves practical considerations beyond just the final appearance.

Clarity vs. Pollen Content

This is the central trade-off. A lower micron number produces clearer honey but removes more pollen. For customers seeking the health benefits of local honey, high pollen content is a feature, not a bug.

The Role of Temperature

Honey is viscous and difficult to process when cold. Gently warming your honey to 95-105°F (35-40°C) will lower its viscosity, allowing it to pass through strainers much more easily.

Crucially, do not overheat it. Temperatures above 110°F can begin to destroy the beneficial enzymes and delicate aromas that make raw honey special.

Speed and Clogging

The finer the mesh, the faster it will clog. Using a two-stage system (coarse then fine) is far more efficient than trying to do everything with a single fine strainer. Be prepared to clean your screens periodically during the process.

Making the Right Choice for Your Goal

Select your straining system based on the kind of honey you aim to produce.

- If your primary focus is personal use or "raw" honey: A single pass through a 600-micron strainer is often enough to produce clean, natural honey with all its pollen intact.

- If your primary focus is appealing, clear honey for a farmer's market: Use a two-stage process, first with a 600-micron strainer and finishing with a 200 or 400-micron strainer.

- If your primary focus is a highly stable, commercial-grade product: This requires ultra-fine filtering (below 40 microns) and heating, which is a different class of processing entirely.

Ultimately, your straining process is a deliberate choice that defines the quality and character of your final product.

Summary Table:

| Micron Level | Purpose | Resulting Honey Character |

|---|---|---|

| 600+ Microns | Coarse Straining | Removes large debris; retains all pollen (ideal for raw honey). |

| 200-400 Microns | Standard Finishing Strain | Clear, saleable honey; removes fine wax but preserves most pollen. |

| Below 40 Microns | Ultra-Fine Filtering | Crystal-clear, commercial-grade; removes all pollen and character. |

Ready to perfect your honey straining process?

As HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale-focused supplies needed for efficient honey processing. From durable strainers to complete extraction systems, our equipment helps you achieve the perfect balance of clarity and quality.

Contact our experts today to discuss the best straining solutions for your operation's scale and goals.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Two-Stage Plastic Honey Filter for Buckets

- Professional Stainless Steel Honey Filter with Support Handle

People Also Ask

- What is the easiest way to strain honey? A Simple Guide for Hobbyist Beekeepers

- What is the primary function of fine-pore filtration consumables in honey processing? Ensure Quality and Purity

- What can I use to sieve honey? The Essential Tool for Clean, High-Quality Honey

- Can honey be filtered? Clarifying Purity, Process, and Pollen

- Why is the selection of fine filtration equipment and consumables critical in the clarification stage of propolis extraction?

- Why is straining important in honey harvesting? Ensure Clean, High-Quality Raw Honey

- What is the primary role of industrial filtration and separation equipment in the purification of propolis?

- What is the primary purpose of honey filters and strainers? Ensure Purity and Clarity in Every Batch