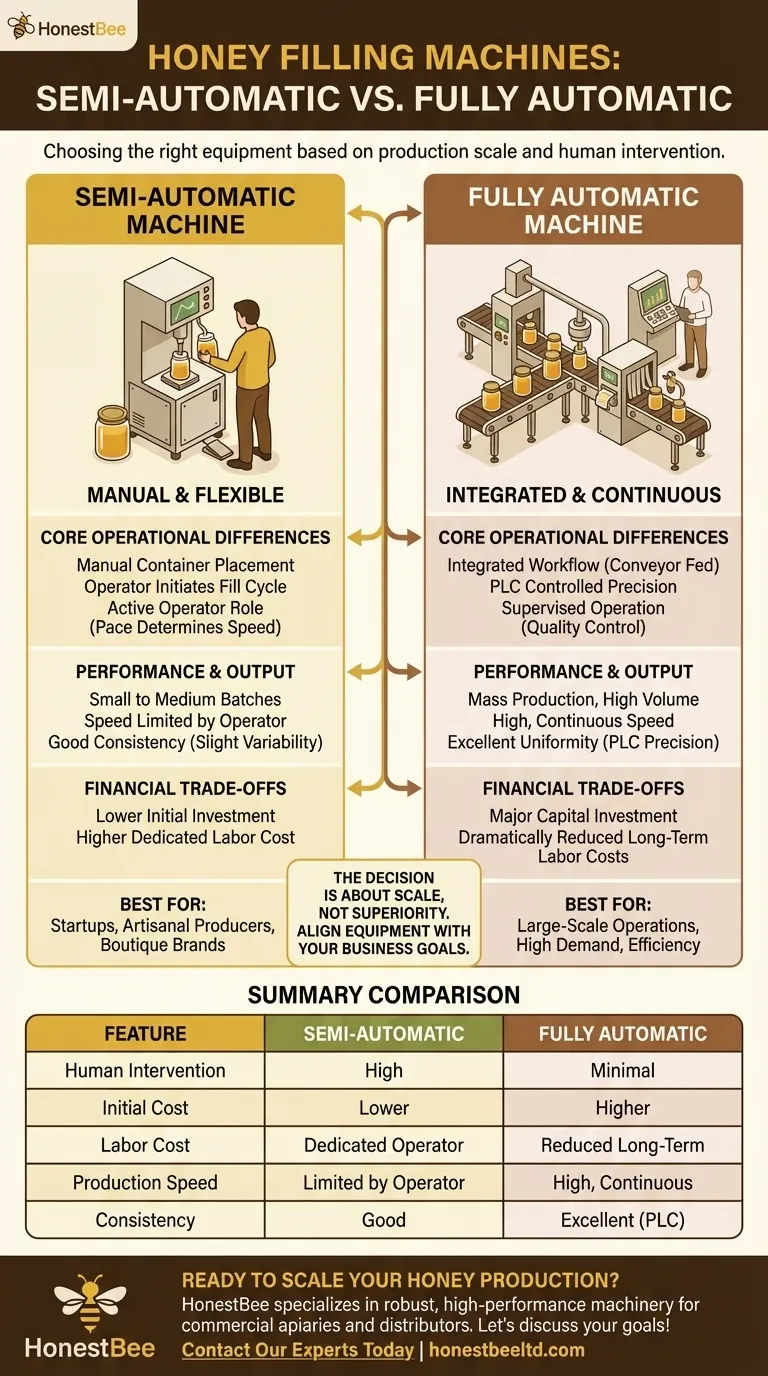

At their core, the difference between semi-automatic and fully automatic honey filling machines comes down to the level of human intervention required. A semi-automatic machine requires an operator to place containers and often initiate the filling cycle, while a fully automatic machine manages the entire process—from placing bottles to filling, capping, and labeling—with minimal human oversight.

The decision is not about which machine is "better," but which one aligns with your business's scale. Semi-automatic machines offer affordability and flexibility for smaller producers, whereas fully automatic systems are a long-term investment in speed, consistency, and reduced labor costs for large-scale operations.

The Core Operational Differences

Understanding how these machines function day-to-day reveals their fundamental design philosophies. The choice directly impacts your workflow, labor needs, and operational consistency.

Manual vs. Integrated Workflow

A semi-automatic machine typically requires an operator to manually place each jar or bottle under the filling nozzle. The operator then uses a foot pedal or button to start the fill cycle for each container individually.

In a fully automatic system, the entire process is integrated. Containers are fed onto a conveyor belt, automatically positioned, filled, capped, and often labeled in a continuous, hands-off sequence.

The Role of the Operator

With a semi-automatic filler, the operator's skill and pace directly determine the production speed and consistency. They are an active part of the production line.

With a fully automatic filler, the operator's role shifts to supervision and quality control. They monitor the machine, replenish supplies like caps and labels, and ensure the system runs smoothly without directly handling each container.

Advanced Process Control

Fully automatic machines almost always incorporate a Programmable Logic Controller (PLC). This is a small industrial computer that controls the machine's functions with high precision, ensuring every container is filled to the exact same level at a consistent speed.

Comparing Performance and Output

Beyond the workflow, the tangible outputs of speed, accuracy, and volume are critical factors in your decision.

Production Speed and Volume

Semi-automatic machines are best suited for small to medium batches. Their speed is limited by how fast the operator can place and remove containers.

Fully automatic machines are designed for mass production. They operate continuously at a much higher speed, making them ideal for large factories aiming to maximize hourly output.

Filling Accuracy and Consistency

While modern semi-automatic machines can be quite accurate, there is often slight variability from one operator to another.

The PLC systems in fully automatic machines deliver exceptional uniformity and precision. This reduces product waste and ensures a consistent customer experience, which is crucial for large brands.

Understanding the Financial Trade-offs

The choice between these systems is a significant financial decision with both immediate and long-term consequences.

Initial Investment

Semi-automatic machines have a significantly lower upfront cost. This makes them an accessible entry point for startups and small-scale artisanal producers with limited capital.

Fully automatic systems represent a major capital investment. The cost includes not just the filler but often the integrated conveyor, capper, and labeling units as well.

Long-Term Operational Costs

The primary operational cost for a semi-automatic machine is the dedicated labor required to run it.

For a fully automatic machine, the higher initial cost is offset over time by dramatically reduced labor costs. This is a key factor in calculating its return on investment (ROI) in a high-volume setting.

Making the Right Choice for Your Business

Your production goals should be the final determinant. There is a clear machine choice depending on your business's current scale and future ambitions.

- If your primary focus is launching a boutique brand or managing a small-scale apiary: A semi-automatic machine provides the necessary functionality and flexibility without a prohibitive initial cost.

- If your primary focus is scaling a growing business to meet high demand: A fully automatic system is the strategic investment needed to achieve efficiency, consistency, and lower per-unit labor costs.

Ultimately, selecting the right machine is about equipping your operation with the tool that best matches its specific production needs.

Summary Table:

| Feature | Semi-Automatic Machine | Fully Automatic Machine |

|---|---|---|

| Human Intervention | High (manual container placement) | Minimal (supervised operation) |

| Best For | Small to medium batches, startups | High-volume, mass production |

| Initial Cost | Lower upfront investment | Higher capital investment |

| Labor Cost | Requires dedicated operator | Reduces long-term labor costs |

| Production Speed | Limited by operator pace | High, continuous output |

| Consistency | Good, with some operator variability | Excellent, with PLC precision |

Ready to Scale Your Honey Production with the Right Equipment?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with the robust, high-performance machinery they need to thrive. Whether you're a growing operation considering your first semi-automatic filler or a large-scale producer ready to invest in a fully automatic line, we provide the durable, wholesale-focused equipment to maximize your efficiency and profitability.

Let's discuss your production goals and find the perfect honey filling solution for your business. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- What is the role of industrial honey-filling machines in enhancing hygiene and economic value? Scale Your Bee Business

- What is the purpose of a heating mechanism in honey filling machines? Achieve Efficient, High-Quality Bottling

- How does the real-time validation mechanism in honey-filling machine software assist operators? Ensure Filling Accuracy

- What technical advantages do industrial-grade honey filling machines provide? Boost Your Commercial Honey Quality

- What role does automated filling and packaging machinery play in the commercialization of stingless bee products?

- What are the benefits of a honey packaging machine's design? Boost Efficiency & Protect Product Quality

- How does the piston filling principle work in honey filling machines? Achieve Precise, High-Viscosity Filling

- How do automated filling production lines improve honey product development? Boost Your Economic Efficiency & ROI