To ensure precision and versatility, the key features to look for in a honey filling machine are digitally adjustable volume controls, mechanisms designed to handle high viscosity, and physical components that can be easily modified for different container sizes. Modern machines use electronic control units for fine-tuning fill amounts, while robust pump systems handle thick honey without compromising speed or accuracy.

Choosing the right honey filler is not just about automation; it's about investing in consistency and flexibility. The best machine is one that masters the dual challenges of honey's difficult nature (viscosity) and your business's need to package it in various forms.

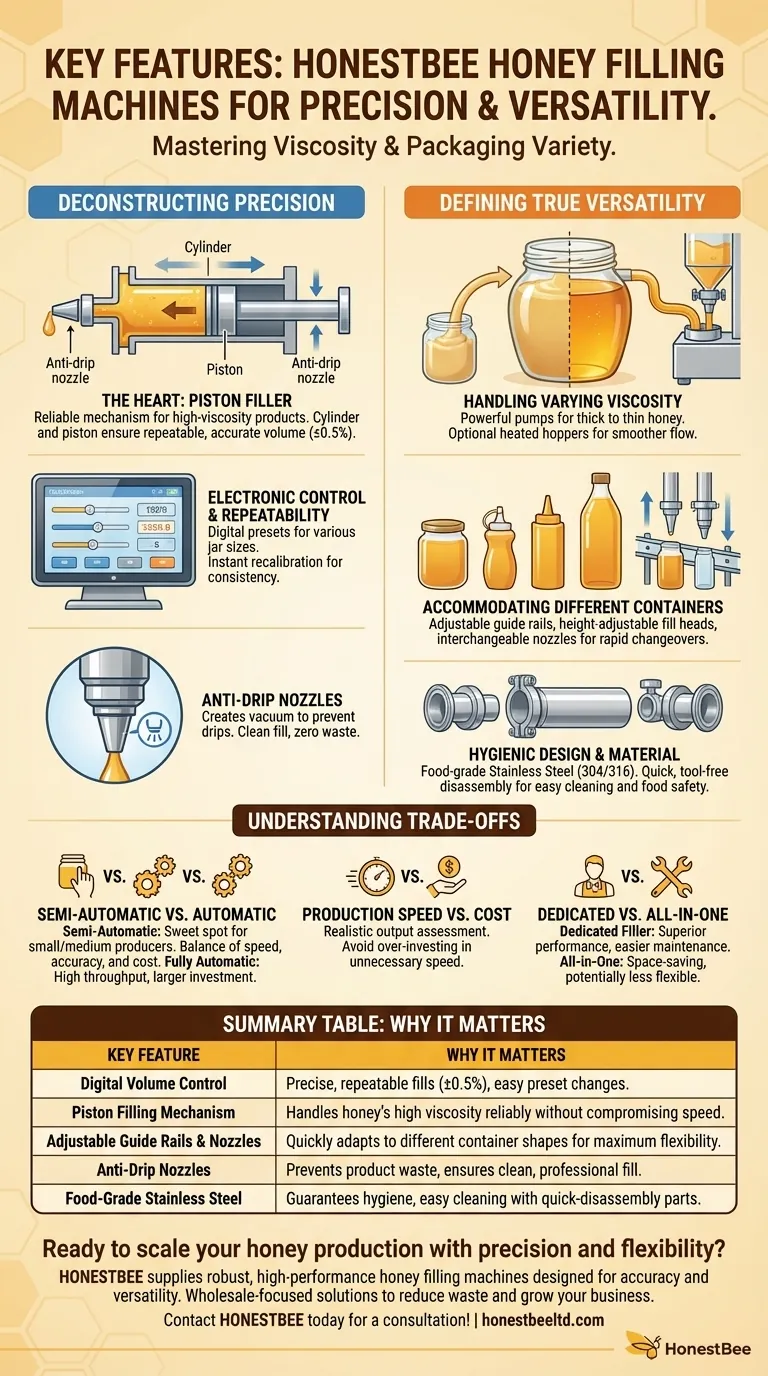

Deconstructing Precision: The Mechanics of an Accurate Fill

Precision is the cornerstone of a professional bottling operation. It ensures every customer gets the same amount of product, reduces costly overfilling, and guarantees compliance with weights and measures regulations.

The Role of the Filling Mechanism

The heart of any filler is its pump system. For a viscous product like honey, a piston filler is the most common and reliable choice. It uses a cylinder to draw in and dispense a precise, repeatable volume of honey.

High-end systems offer accuracy better than ±0.5%, which translates to minimal product waste and consistent jar appearance.

Electronic Control and Repeatability

Modern machines feature a central electronic control unit. This digital interface is far superior to purely mechanical controls, allowing you to save exact fill volume settings as presets for different jar sizes.

This ensures that when you switch from filling 8oz jars to 16oz jars, the machine recalibrates perfectly with the touch of a button, guaranteeing repeatable accuracy across every batch.

The Importance of Anti-Drip Nozzles

A clean fill is part of a precise fill. Look for machines equipped with anti-drip or suck-back nozzles. After dispensing the honey, these nozzles create a slight vacuum to pull back any potential drips.

This small feature has a massive impact, preventing messy containers, sticky machine surfaces, and the slow accumulation of wasted product.

Defining True Versatility for Your Operation

Versatility determines how well a machine can adapt to your current products and grow with your future needs. It’s about more than just speed; it’s about flexibility in your packaging process.

Handling Varying Honey Viscosity

Honey's viscosity changes dramatically based on floral source, temperature, and crystallization. A versatile machine must have a powerful enough filling system to handle thick, creamy honey just as easily as thin, liquid honey.

Piston fillers excel here, as the piston's force is highly effective at moving thick products. Some machines also include a heated hopper to gently warm the honey, reducing its viscosity for a smoother, faster fill.

Accommodating Different Containers

Your product line may include glass jars, plastic squeeze bottles, and various novelty shapes. True versatility means the machine can adapt with minimal downtime.

Look for key adjustable features:

- Adjustable guide rails to center different container widths under the nozzle.

- Height-adjustable fill heads to accommodate tall and short jars.

- Interchangeable nozzles for wide-mouth jars versus narrow-bottle openings.

Hygienic Design and Material Choice

A machine made from food-grade stainless steel (like 304 or 316) is non-negotiable for hygiene. Beyond the material, look for a design that is easy to clean.

Parts that contact the honey should be connected with tri-clamp fittings, allowing for quick, tool-free disassembly. This is critical for preventing cross-contamination between different honey varietals and ensuring food safety.

Understanding the Trade-offs

Every equipment decision involves balancing cost, features, and operational complexity. Understanding these trade-offs is key to making the right investment.

Manual vs. Semi-Automatic vs. Automatic

A semi-automatic machine is often the sweet spot for small to medium producers. An operator places the jar, and the machine fills it with the press of a pedal or button. This provides excellent accuracy and speed over manual filling without the cost of a fully automated line.

Fully automatic lines integrate conveyors, container positioning, and sometimes even capping. They offer the highest throughput but come with a significant price increase and greater mechanical complexity.

Production Speed vs. Cost

A machine that can fill 1,000 jars per hour costs significantly more than one that fills 300. Be realistic about your current and near-future production volume. Paying for speed you don't need is a common mistake that diverts capital from other areas of your business.

Dedicated vs. All-in-One Systems

Some manufacturers offer "monoblock" systems that combine filling, capping, and labeling in one chassis. While this saves space, it can be less flexible than purchasing specialized, separate machines. A dedicated filler often provides superior performance and is easier to service or upgrade independently.

Making the Right Choice for Your Goal

Your ideal machine depends entirely on your operational scale and business objectives.

- If your primary focus is starting out with small, high-quality batches: A tabletop semi-automatic piston filler offers the best balance of precision, affordability, and ease of cleaning.

- If your primary focus is scaling with multiple jar sizes and honey types: Prioritize a semi-automatic filler with an electronic control unit for presets and quick-disassembly parts for fast cleaning changeovers.

- If your primary focus is maximizing output and labor efficiency: A fully automatic inline filling system is the correct choice, but be prepared for a substantial investment in both capital and operator training.

Ultimately, the right machine is an investment that removes operational bottlenecks and empowers you to focus on growing your business.

Summary Table:

| Key Feature | Why It Matters |

|---|---|

| Digital Volume Control | Ensures precise, repeatable fills (±0.5% accuracy) and easy preset changes for different jar sizes. |

| Piston Filling Mechanism | Handles honey's high viscosity reliably, from thick creams to liquid honey, without compromising speed. |

| Adjustable Guide Rails & Nozzles | Quickly adapts to different container shapes and sizes (jars, bottles) for maximum operational flexibility. |

| Anti-Drip Nozzles | Prevents product waste and messy containers, ensuring a clean, professional fill every time. |

| Food-Grade Stainless Steel | Guarantees hygiene and easy cleaning with quick-disassembly parts to prevent cross-contamination. |

Ready to scale your honey production with precision and flexibility?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, high-performance honey filling machines designed for accuracy and versatility. Our wholesale-focused operations ensure you get the right equipment to eliminate bottlenecks, reduce waste, and grow your business.

Contact HONESTBEE today for a consultation on the perfect filling solution for your operation!

Visual Guide

Related Products

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Manual Honey Filling Machine Bottling Machine for Honey

- Fully Automatic Honey Filling Packaging Machine for Processing Line

People Also Ask

- What are the types of bottle filling machines? Find the Perfect Match for Your Product

- What role do honey-filling machines play in the commercialization of wild honey? From Raw Harvest to Global Retail

- What are the technical advantages of using industrial-grade honey filling machines for market channel expansion?

- What are the advantages of using automatic honey filling machines? Maintain Purity and Bioactivity in Commercial Honey

- What are the different types of filling mechanisms used in honey filling machines? Choose the Right Tech for Your Honey

- What are the economic benefits of automated honey filling systems? Boost ROI in Large-Scale Commercial Apiaries

- Why is a professional honey-filling machine necessary? Master High-Viscosity Specialty Honey Bottling

- Why are industrial-grade honey filling machines necessary? Scale Your Apiary with Professional Processing Efficiency