Immediately after filtering, the honey is prepared for its final use through a process of bottling and packaging. This readies the honey for personal consumption, gifting, or sale, transforming it from a raw hive product into a finished good ready for the pantry or marketplace.

The post-extraction journey is about final purification and packaging. Once debris is removed, honey is decanted to settle, then transferred into jars or containers, with the specific methods determined by the beekeeper's scale—from a hobbyist's kitchen to a commercial bottling line.

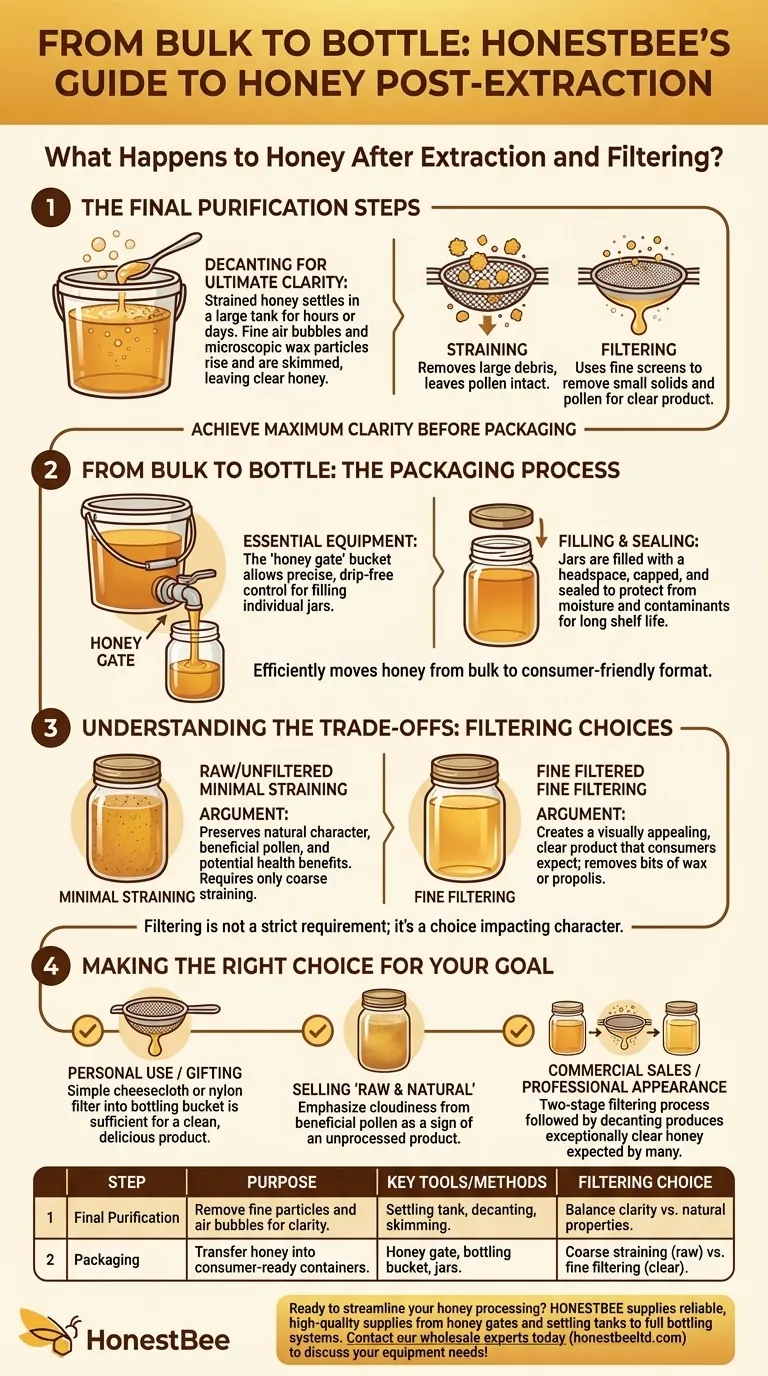

The Final Purification Steps

After the initial filtering removes the largest particles like beeswax and bee parts, a final settling phase is often employed to achieve maximum clarity before the honey is packaged.

The Role of Straining vs. Filtering

While often used interchangeably, straining and filtering serve different purposes. Straining, typically done with cheesecloth or a coarse mesh, removes large debris while leaving fine particles like pollen intact.

Filtering, on the other hand, can use much finer screens to remove even small solids and pollen grains, resulting in a clearer, more transparent final product.

Decanting for Ultimate Clarity

For the highest level of purity, beekeepers let the strained honey sit in a large container, often called a settling tank or decanting bucket, for several hours or days.

This allows any remaining fine air bubbles or microscopic particles of wax to rise to the surface. This top layer can then be skimmed off, leaving behind exceptionally clear honey ready for bottling.

From Bulk to Bottle: The Packaging Process

Packaging is the crucial step that moves honey from a bulk container into a consumer-friendly format. The right equipment makes this process efficient and clean.

Essential Bottling Equipment

The most common tool for small-scale bottling is a bucket with a bottom latch, often called a "honey gate." This simple valve allows for precise, drip-free control when filling individual jars.

Larger operations may use a combined honey sieve and bottling tank, which streamlines the filtering and packaging into a single, more efficient workflow.

Filling and Sealing the Jars

Using the honey gate, jars are filled one by one, leaving a small amount of headspace at the top. Once filled, they are capped and sealed to protect the honey from moisture and contaminants, ensuring a long shelf life.

Understanding the Trade-offs: Filtering Choices

The decision of how much to filter honey is not just technical; it's a choice that impacts the final product's character and appeal. Filtering is not a strict requirement.

The Argument for Fine Filtering

Many consumers expect honey to be crystal clear and free of any visible particles. Filtering creates a visually appealing product that looks "clean" on a store shelf and removes bits of propolis or wax that some find undesirable.

The Argument for Minimal Straining

Conversely, many enthusiasts and health-conscious consumers seek out "raw" or unfiltered honey. They believe that leaving pollen and other microscopic elements in the honey preserves its natural character and potential health benefits. This approach simply requires a coarse straining to remove only the largest non-honey debris.

Making the Right Choice for Your Goal

The final steps you take depend entirely on what you plan to do with the honey. Your end goal dictates the process.

- If your primary focus is personal use or gifting: A simple straining through cheesecloth or a nylon filter into a bottling bucket is perfectly sufficient to create a clean, delicious product.

- If your primary focus is selling a "raw and natural" product: Minimal straining is key. Emphasize that the cloudiness is from beneficial pollen and a sign of an unprocessed product.

- If your primary focus is commercial sales or a professional appearance: A two-stage filtering process followed by decanting will produce the exceptionally clear honey that many consumers expect.

Ultimately, packaging your own honey is the final, rewarding step in the journey from hive to home.

Summary Table:

| Step | Purpose | Key Tools/Methods |

|---|---|---|

| Final Purification | Remove fine particles and air bubbles for clarity. | Settling tank, decanting, skimming. |

| Packaging | Transfer honey into consumer-ready containers. | Honey gate, bottling bucket, jars. |

| Filtering Choice | Balance clarity vs. natural properties (e.g., pollen). | Coarse straining (raw) vs. fine filtering (clear). |

Ready to streamline your honey processing? Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE supplies the reliable, high-quality supplies you need—from honey gates and settling tanks to full bottling systems. Let us help you achieve a perfect final product. Contact our wholesale experts today to discuss your equipment needs!

Visual Guide

Related Products

- Hexagonal Glass Honey Jars with Metal Lug Caps Elegant Versatile Packaging

- Classic Drum Shaped Glass Honey Jar with Airtight Lid

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- Why is it necessary to use storage containers with tight-fitting lids? Prevent Honey Spoilage and Loss

- How does the appearance of glass jar packaging affect the sales and perception of honey? Boost Your Premium Brand Value

- What key functions do high-quality packaging materials serve? Unlock the Commercial Potential of Your Honey

- Why are Glass Jars preferred as storage equipment for honey? The Ultimate Choice for Purity and Long-Term Quality

- Why are transparent glass containers utilized in honey storage stability studies? Simulating Real-World Quality Decay