The best way to bottle honey is to focus on two non-negotiable goals: preserving its quality by keeping it sealed from air and choosing a container that suits your needs. The specific method you use—whether manual or automated—is secondary to ensuring the honey remains pure, its moisture content stays low, and it is stored in a way that makes future use practical.

The "best" bottling method is not about the machine you use, but about the principles you follow. Your primary objective is to protect the honey from moisture and plan for inevitable crystallization, ensuring the quality of your harvest is maintained for years to come.

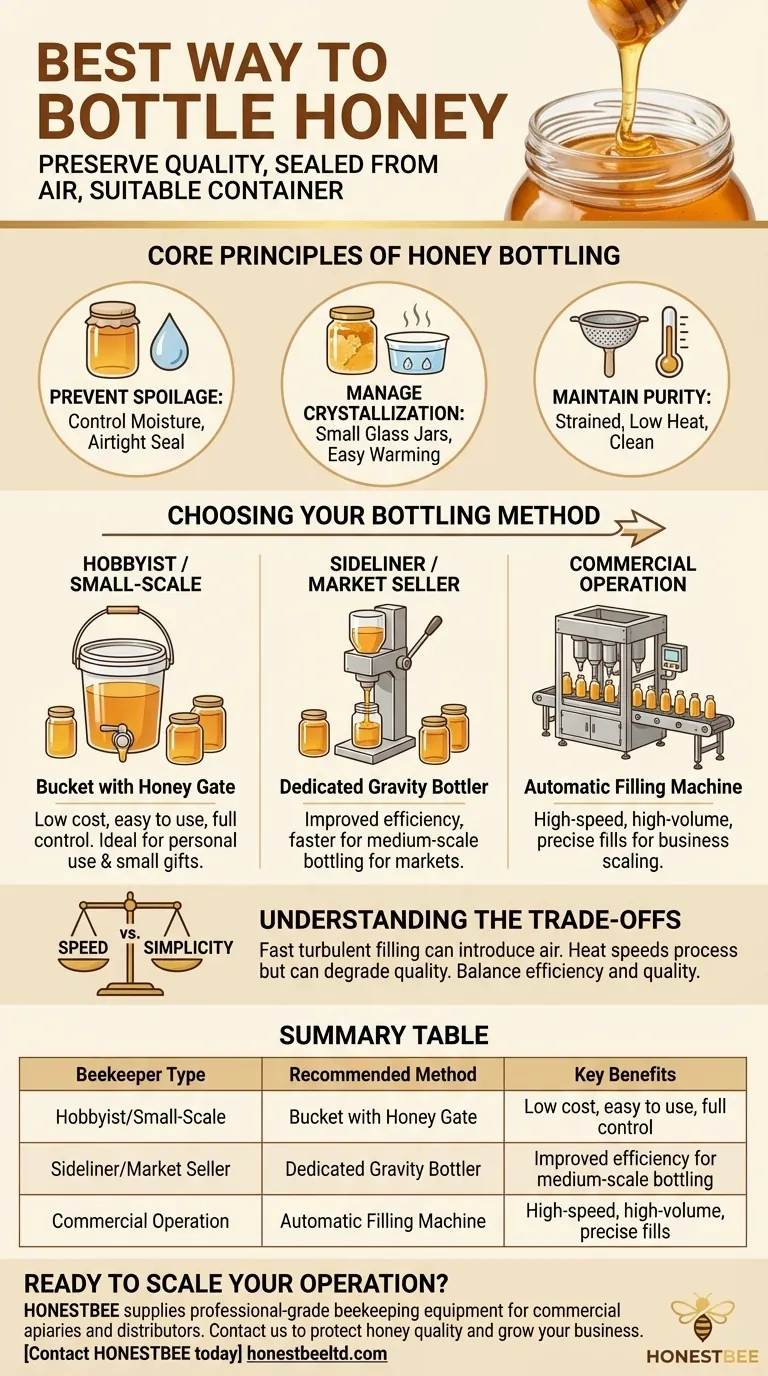

The Core Principles of Honey Bottling

Before choosing any equipment, you must understand the nature of honey. How you handle it during bottling directly impacts its shelf life and quality.

Preventing Spoilage by Controlling Moisture

Honey is hygroscopic, meaning it actively absorbs moisture from the surrounding air. If the honey’s moisture content rises above approximately 18%, naturally present yeasts can begin to ferment, spoiling the batch.

The single most important step in bottling is to create an airtight seal. This prevents moisture absorption and is the key to long-term preservation.

Managing Inevitable Crystallization

Crystallization is a natural process that will happen to almost all raw honey over time. It is not a sign of spoilage. However, bottling with this in mind will save you significant effort later.

Storing honey in small glass jars is far superior to keeping it in large buckets. A crystallized five-gallon bucket is extremely difficult to re-liquefy, while a small jar can be gently warmed in a water bath to return the honey to its liquid state.

Maintaining Purity and Flavor

Proper bottling also means keeping the honey clean. Ensure your honey has been strained to remove wax particles and other debris before it goes into the jar.

Avoid overheating honey during the process. Excessive heat can destroy beneficial enzymes and alter the honey's delicate flavor profile. If you must warm honey to make it flow easier for bottling, do so gently and keep the temperature as low as possible.

Choosing Your Bottling Method

The right equipment depends entirely on your scale, from a few jars for the family to thousands for a commercial brand.

For the Hobbyist or Small-Scale Beekeeper

For small harvests, a simple and effective method is using a bucket with a honey gate (a spigot at the bottom). This is a form of gravity bottling, using gravity to fill one jar at a time.

This method is low-cost, easy to clean, and gives you complete control over the filling process. It is the ideal starting point for anyone bottling for personal use, gifts, or a very small number of sales.

For the Growing Sideliner or Market Beekeeper

As your operation grows, a dedicated gravity bottler becomes a worthwhile investment. These systems often hold more honey and may have features to make filling faster and cleaner than a simple bucket gate.

They still rely on gravity but are designed specifically for the task, improving efficiency for those bottling dozens or hundreds of jars for farmers' markets or local stores.

For the Commercial Operation

Commercial beekeepers require high efficiency to be profitable. An automatic filling machine is the standard for this scale.

These machines can fill multiple bottles at once with precise volumes, dramatically increasing output. They are a significant investment but are essential for any operation producing honey at a commercial level.

Understanding the Trade-offs

Every method comes with considerations. Choosing the right one involves balancing speed, cost, and the potential impact on your honey.

Speed vs. Cost and Simplicity

The primary trade-off is between speed and cost. A simple bucket and gate is very inexpensive but slow. An automatic filler is incredibly fast but requires a major capital investment and more complex maintenance.

The Risk of Introducing Air

Fast, turbulent filling can introduce air bubbles into the honey. This can affect the visual clarity of the final product and, in a worst-case scenario, trap microscopic pockets of air and moisture against the honey.

A slower, more controlled fill from the bottom of the jar is always preferable to minimize aeration, regardless of the method you use.

Heat and Honey Quality

Some bottling systems incorporate heaters to keep the honey flowing quickly. Be extremely cautious with heat. While it speeds up the process, overheating can degrade the honey. If you use heat, use the absolute minimum required.

Making the Right Choice for Your Goal

Your bottling strategy should be a direct reflection of your goals as a beekeeper.

- If your primary focus is personal use or small gifts: A simple bucket with a honey gate and airtight glass jars is all you need to preserve your harvest perfectly.

- If your primary focus is selling at local markets: A dedicated gravity bottler will provide the efficiency boost you need without the high cost of commercial equipment.

- If your primary focus is scaling a commercial business: An automatic filling machine is a necessary investment to ensure consistent, high-volume production.

Ultimately, bottling is the final step in honoring the hard work of your bees; choose the method that best protects the quality of their product.

Summary Table:

| Beekeeper Type | Recommended Method | Key Benefits |

|---|---|---|

| Hobbyist / Small-Scale | Bucket with Honey Gate | Low cost, easy to use, full control |

| Sideliner / Market Seller | Dedicated Gravity Bottler | Improved efficiency for medium-scale bottling |

| Commercial Operation | Automatic Filling Machine | High-speed, high-volume, precise fills |

Ready to scale your honey bottling operation with professional-grade equipment?

HONESTBEE supplies beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through wholesale-focused operations. We can provide the durable, efficient bottling equipment you need to protect your honey's quality and grow your business.

Contact HONESTBEE today to discuss your specific needs and get a quote on the right bottling solution for your apiary!

Visual Guide

Related Products

- Classic Drum Shaped Glass Honey Jar with Airtight Lid

- Hexagonal Glass Honey Jars with Metal Lug Caps Elegant Versatile Packaging

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- What are the advantages of using high-precision filling machines when converting honey into commercial merchandise?

- Why are high-precision honey-filling machines necessary for stingless bee honey? Ensure Accuracy & Prevent Fermentation

- What is the primary function of medical-grade syringes in stingless bee honey collection? Ensure Purity & Integrity

- How does the integration of automated honey-filling machines with hive recognition technology create value? Optimize Now

- How do automatic honey filling and capping machines improve the profitability of beekeeping enterprises?

- What additional support is available for selecting a honey packaging machine? Get Expert Guidance for Your Apiary

- In what ways do industrial-grade honey filtration and automatic bottling equipment enhance the quality of honey products?

- What are the different types of seals created by a honey stick machine? Choose the Right Seal for Your Honey Sticks