The cut and strain method is a traditional and straightforward way to separate honey from its wax comb. It involves physically cutting the honeycomb from the frame, crushing it to break open the wax cells, and then pouring the mixture through a filter or sieve to strain the liquid honey from the solid pieces of wax.

This approach is a low-cost alternative to mechanical extraction, prized for its simplicity and its tendency to produce honey rich in pollen. However, its defining characteristic is that it completely sacrifices the wax comb in the process.

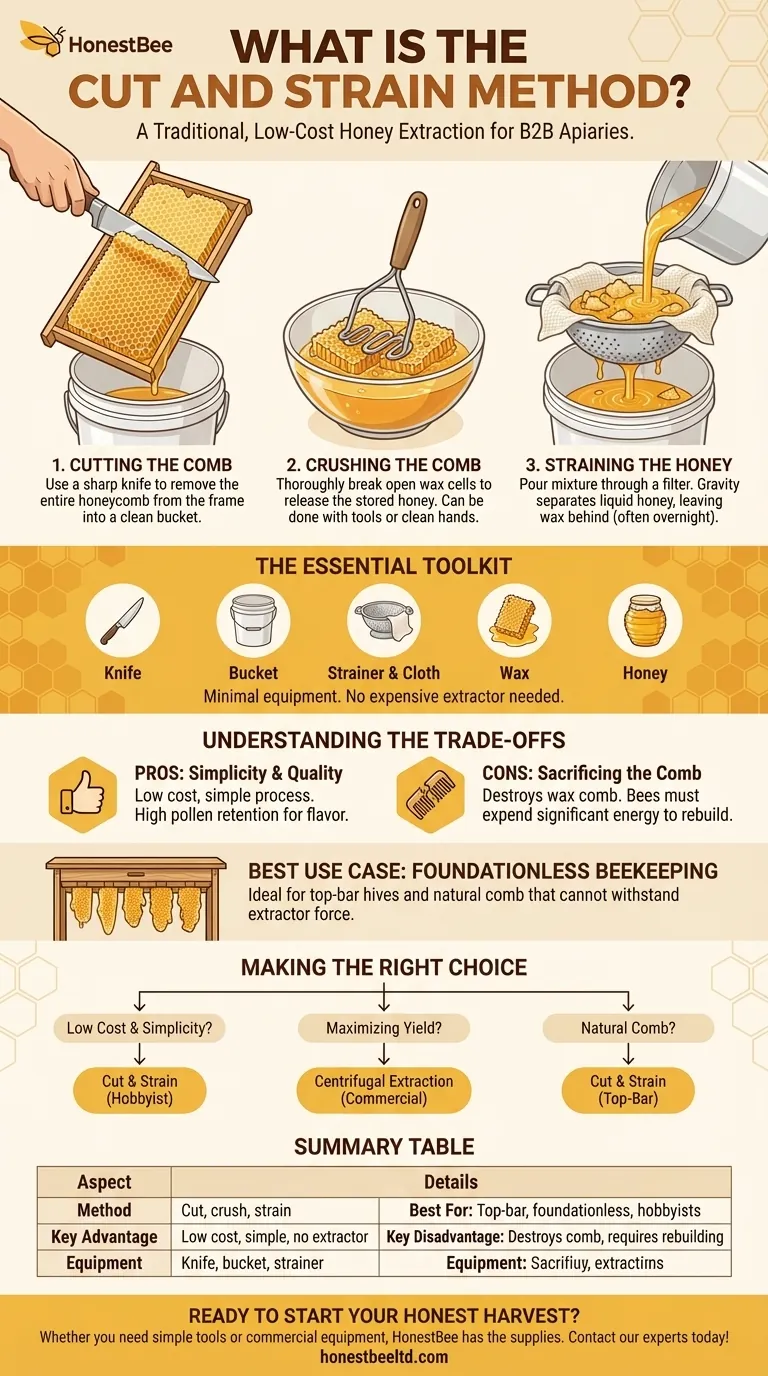

How the Cut and Strain Method Works

This process relies on gravity and basic filtration rather than the centrifugal force used in mechanical extractors. It's a hands-on method that can be done with common kitchen equipment.

Step 1: Cutting the Comb

The process begins by using a sharp knife to cut the entire honeycomb away from the wooden frame or top bar it was built on. This is placed into a clean, food-grade bucket or large bowl.

Step 2: Crushing the Comb

Once in the container, the comb is thoroughly crushed. This can be done with a potato masher or even clean hands. The goal is to break open every single wax cell to release the honey stored inside.

Step 3: Straining the Honey

The crushed mixture of honey and wax is then poured through a strainer. This is typically a colander lined with cheesecloth or a purpose-made honey filter placed over a clean bottling bucket.

Gravity slowly pulls the liquid honey through the filter, leaving the chunks of wax behind. This process can take several hours and is often left overnight. Performing this in a warm room will lower the honey's viscosity and speed up the draining.

The Essential Toolkit for Cut and Strain

One of the primary appeals of this method is the minimal need for specialized or expensive equipment. You can get started with a very simple setup.

The Bare Necessities

At its core, all you need is a sharp knife for cutting the comb, a food-grade bucket for crushing, and a straining system like a colander and filter cloth.

Why an Extractor Isn't Needed

This method completely bypasses the need for a centrifugal honey extractor, which is often the most expensive piece of equipment for a new beekeeper. This makes it an accessible entry point into honey harvesting.

Understanding the Trade-offs

Choosing an extraction method involves balancing efficiency, cost, and the impact on both the honey and the bees. The cut and strain method has very clear pros and cons.

The Advantage: Simplicity and Quality

This is the simplest, lowest-cost extraction method. Because it avoids high-speed spinning and extensive processing, the resulting honey often retains more of its original pollen, which can contribute to a more pronounced flavor and perceived nutritional value.

The Disadvantage: Sacrificing the Comb

The critical trade-off is the destruction of the wax comb. Bees expend enormous energy to produce wax and draw it into a perfect honeycomb structure. When the comb is destroyed, they must rebuild it from scratch, consuming significant honey resources that could have otherwise been stored as surplus.

The Best Use Case: Foundationless Beekeeping

This method is the standard for hives where the comb is not built on a pre-made foundation, such as in top-bar hives or foundationless Langstroth frames. In these cases, the delicate comb cannot withstand the force of a mechanical extractor, making cut and strain the most practical option.

Making the Right Choice for Your Goal

Your beekeeping style and goals will determine if this method is right for you.

- If your primary focus is low start-up cost and simplicity: The cut and strain method is the ideal choice for a hobbyist with one or two hives.

- If your primary focus is maximizing honey yield over time: Centrifugal extraction is superior because preserving the drawn comb allows bees to refill it quickly, saving them immense energy.

- If your primary focus is a top-bar hive or natural comb: The cut and strain method is not just an option but the necessary and standard approach.

Choosing the cut and strain method is about trading the bees' comb for a simple, accessible, and natural extraction process.

Summary Table:

| Aspect | Details |

|---|---|

| Method | Physically cut, crush, and strain honeycomb |

| Best For | Top-bar hives, foundationless frames, hobbyists |

| Key Advantage | Low cost, simple process, no extractor needed |

| Key Disadvantage | Destroys wax comb, requiring bees to rebuild |

| Equipment Needed | Knife, bucket, strainer/filter cloth |

Ready to Start Your Honey Harvest?

Whether you're a hobbyist starting with the cut and strain method or a commercial apiary scaling up with centrifugal extractors, HONESTBEE has the supplies and equipment you need. We supply beekeeping equipment and supplies to commercial apiaries and distributors through wholesale-focused operations.

Let us help you choose the right tools for a successful harvest. Contact our experts today to discuss your needs!

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- Stainless Steel 3 Frame Manual Honey Extractor Spinner for Bee Honey Extraction

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- What tool is used to extract honey? The Essential Guide to Honey Extractors & Harvesting

- What are the primary functions of industrial-grade honey extraction and filling equipment? Scale Your Commercial Production

- How do automated honey extractors help in preserving honeycomb integrity? Boost Hive Productivity and Reuse Wax

- What is the relationship between beeswax harvesting and honey extraction? An Inseparable Process Explained

- What are the differences between manual and automatic honey extractors? Choose the Right Tool for Your Apiary

- What preparation is needed for honey extraction using a honey extractor? A Step-by-Step Guide to a Clean Harvest

- What are the core technical functions of centrifugal honey extractors? Boost Yield with Advanced Extraction

- Why do large-scale commercial apiaries prefer electric honey extractors? Boost Efficiency & Maximize Yield