The primary drawback of the conventional honey drying method is its reliance on high heat. This thermal process degrades the honey's quality by creating a chemical byproduct called Hydroxymethylfurfural (HMF), which serves as a key indicator of heat damage and alters the honey's natural flavor and aroma.

The core issue with conventional drying is a fundamental trade-off: in the pursuit of removing moisture to prevent fermentation, the application of high heat damages the very chemical and aromatic compounds that define high-quality, natural honey.

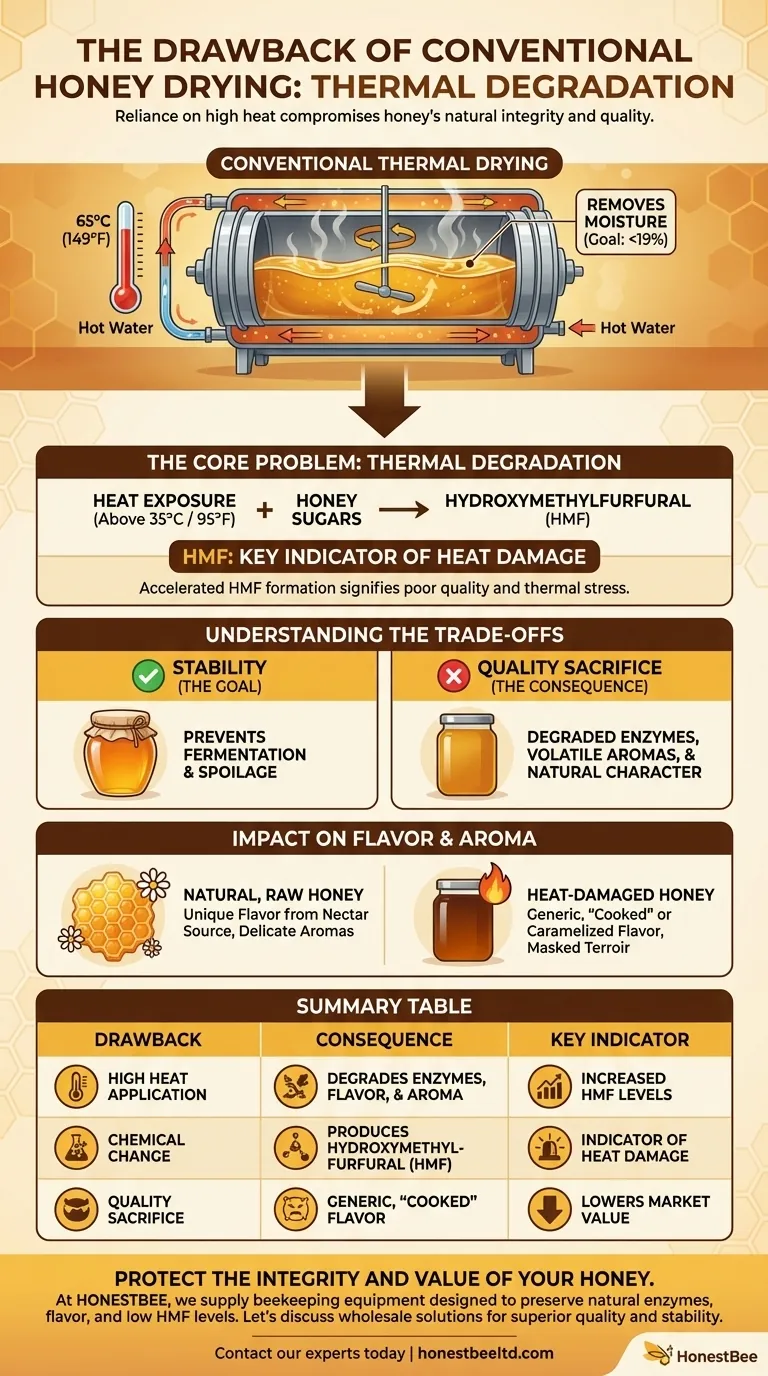

The Core Problem: Thermal Degradation

The conventional approach to drying honey solves one problem (excess moisture) but creates another, more significant one (reduced quality). This degradation is a direct result of the heating process itself.

How Conventional Drying Works

The standard industrial method involves placing honey in a large, jacketed drum. Hot water, often heated to 65°C (149°F), is circulated through the outer jacket.

This indirectly heats the honey while it is continuously stirred. The goal is to evaporate excess water, typically reducing the moisture content from a range of 25-30% down to a stable level of 19%.

The Unintended Chemical Consequence: HMF

When the sugars in honey are exposed to heat above 35°C (95°F), a chemical reaction occurs, forming Hydroxymethylfurfural (HMF).

HMF is a compound that is naturally present in honey in very small amounts. However, heating accelerates its formation dramatically, and its concentration is used globally as a primary marker for honey that has been overheated or is old.

Why HMF Content Matters

High HMF content is an internationally recognized indicator of poor honey quality. Regulatory standards and commercial buyers often have strict limits on acceptable HMF levels.

Elevated levels signify that the honey has been subjected to thermal stress, which not only impacts its classification but also directly degrades its sensory profile.

Understanding the Trade-offs

Producers use thermal drying for a specific reason, but the consequences of this choice must be clearly understood.

The Goal: Stability vs. Quality

The primary motivation for drying honey is to achieve shelf stability. Honey with a moisture content above 20% is susceptible to fermentation by naturally occurring yeasts.

Conventional drying effectively prevents this spoilage. However, it sacrifices the delicate enzymes, volatile aromatic compounds, and natural character that command a premium price.

The Impact on Flavor and Aroma

The delicate and unique flavor profile of honey comes from the specific nectar source. Heat destroys these subtle notes.

The result of thermal drying is a more generic, often slightly "cooked" or caramelized flavor. This makes the honey far less desirable to consumers seeking a natural, raw product and masks the unique terroir of its origin.

Making the Right Choice for Your Goal

When evaluating honey or choosing a processing method, the decision must be aligned with the desired quality of the final product.

- If your primary focus is bulk production and long-term stability: Conventional thermal drying achieves this quickly, but be prepared for a significant reduction in quality and a lower market value for your product.

- If your primary focus is a premium, high-quality product: You must use non-thermal or low-temperature drying methods to preserve the honey's natural enzymes, flavor, and low HMF levels.

Ultimately, understanding the damaging effects of heat is critical to preserving the true integrity and value of honey.

Summary Table:

| Drawback | Consequence | Key Indicator |

|---|---|---|

| High Heat Application | Degrades natural enzymes, flavor, and aroma. | Increased HMF levels. |

| Chemical Change | Produces Hydroxymethylfurfural (HMF). | Indicator of heat damage and poor quality. |

| Quality Sacrifice | Results in a generic, 'cooked' flavor profile. | Lowers market value for premium products. |

Protect the integrity and value of your honey.

As a commercial apiary or distributor, your reputation depends on delivering high-quality honey. The conventional high-heat drying method directly compromises the very qualities that make your product premium. At HONESTBEE, we supply beekeeping equipment and supplies designed to help you preserve the natural enzymes, flavor, and low HMF levels that discerning customers demand.

Let's discuss how our wholesale-focused solutions can help you achieve superior quality and stability.

Contact our experts today to explore your options

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Stainless Steel Triangle Support Honey Strainer and Filters

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- How does the honey dryer operate to process honey? Master Gentle Moisture Removal for High-Quality Results

- What is the primary role of an automated temperature and humidity control honey drying cabinet? Ensure Honey Quality.

- Why is specialized dehydration equipment necessary for stingless bee honey? Preserve Quality and Prevent Fermentation

- Why is convective drying equipment with dehumidification recommended for Bee Bread? Preserve Potency with Low Heat

- Why is it necessary to maintain honey water content below 20%? Prevent Fermentation & Ensure Professional Quality

- What safety precautions must be taken regarding the moisture content of ingredients used in honey infusion? Prevent Mold

- Does honey draw out moisture? The Science of Honey's Hygroscopic Nature

- What is the significance of axial fans in honey drying? Ensure Batch Consistency with Laminar Flow