The fastest way to melt beeswax is to use a double boiler on a stovetop after first breaking or cutting the solid wax into small, uniform chunks of about one to two inches. This method provides strong, consistent, and controllable indirect heat. The smaller pieces dramatically increase the surface area, allowing the wax to absorb heat and melt much more quickly and evenly.

The core challenge isn't just melting beeswax quickly, but doing so without compromising its quality or creating a fire hazard. The fastest and safest method combines maximizing the wax's surface area with a controlled, indirect heat source like a double boiler.

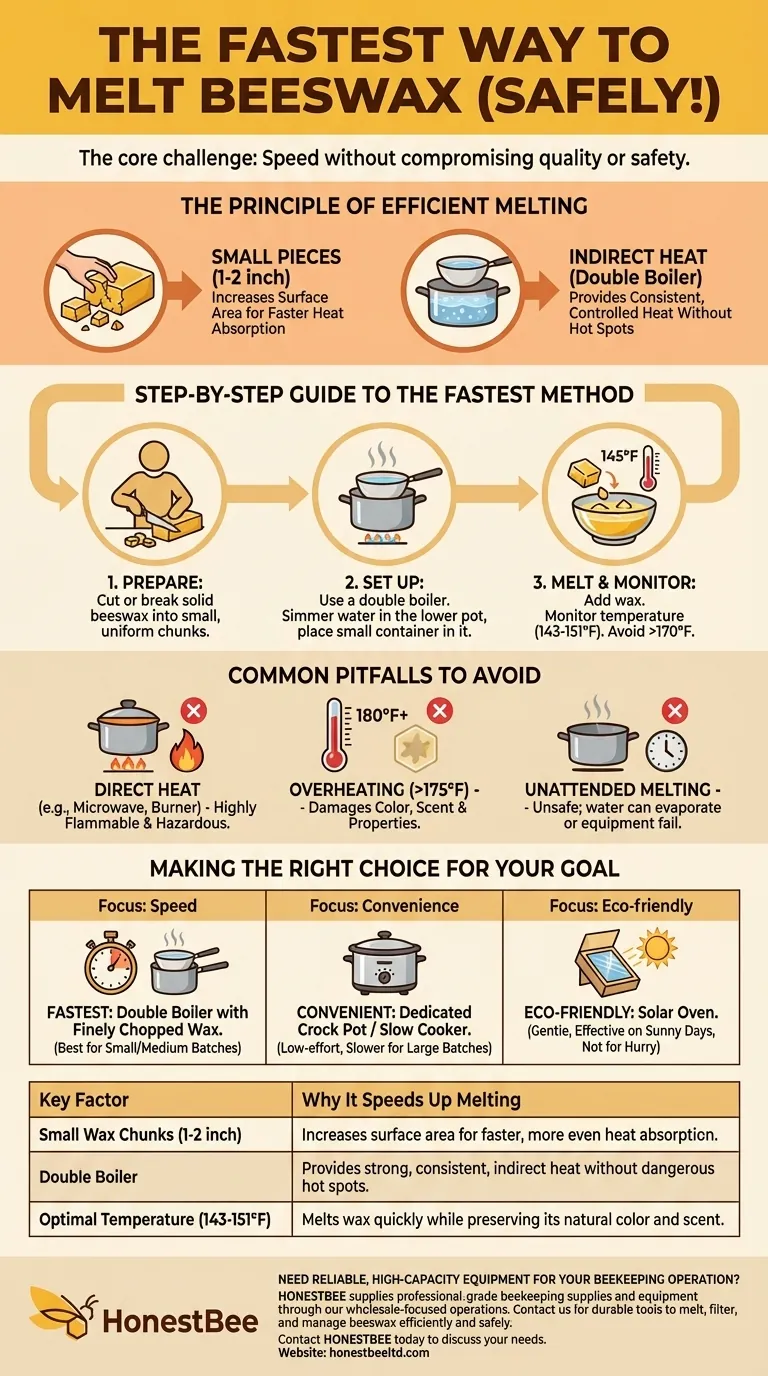

The Principle of Efficient Melting

To melt beeswax quickly, you need to understand two simple factors: how the wax absorbs heat and how that heat is applied.

Why Small Pieces are Essential

The single most effective step you can take to speed up the process is to increase the wax's surface area.

A large, solid block of beeswax will melt slowly from the outside in. By breaking it into small, 1-2 inch chunks, you expose significantly more of the wax to the heat source simultaneously, leading to a rapid and uniform melt.

The Role of Controlled, Indirect Heat

Beeswax is flammable and can be damaged by excessive temperatures. Applying heat directly from a flame or electric burner creates hot spots that can scorch the wax and pose a serious fire risk.

A double boiler is the ideal solution. It uses steam from simmering water to gently and evenly heat the bottom of the melting container, providing powerful heat transfer without the danger of direct contact.

A Step-by-Step Guide to the Fastest Method

Following these steps ensures a melt that is both fast and safe.

Step 1: Prepare Your Workspace and Wax

Use dedicated pots and utensils for beeswax, as it is difficult to clean from kitchenware.

Cut or break your block of beeswax into small, uniform chunks. The smaller the pieces, the faster the melt.

Step 2: Set Up the Double Boiler

Fill a large stockpot with a few inches of water and bring it to a boil, then reduce it to a steady simmer.

Place a smaller, heat-safe bowl or saucepan (metal is ideal) inside the larger pot. Ensure it rests securely on the rim, with its bottom hovering above the simmering water, not touching it.

Step 3: Melt and Monitor Carefully

Place your beeswax chunks into the smaller, dry container. The indirect heat from the steam will begin to melt it almost immediately.

Use a thermometer to monitor the temperature. Beeswax melts between 143-151°F (61-66°C). Do not allow the temperature to exceed 170°F (77°C) to prevent discoloration and loss of its natural aroma.

Common Pitfalls to Avoid

Chasing speed can lead to dangerous mistakes. Understanding the limitations of beeswax is critical for a successful outcome.

The Danger of Direct Heat

Never attempt to melt beeswax directly in a pot on a burner or in a microwave. Beeswax is flammable, and its vapors can ignite if it reaches its flash point. Direct heat creates uncontrollable hot spots, making this approach extremely hazardous.

The Risk of Overheating

Heating beeswax above 175°F not only causes it to lose its desirable color and scent but can also degrade its natural anti-microbial properties. Always use a thermometer and maintain control.

The Hazard of Being Unattended

Melting wax should never be left unattended, regardless of the method. The water in a double boiler can evaporate, or a thermostat could fail, creating an unsafe situation quickly.

Making the Right Choice for Your Goal

While the double boiler is fastest, other methods may suit different needs.

- If your primary focus is maximum speed for a small to medium batch: Use a double boiler with finely chopped wax.

- If your primary focus is convenience for a large batch: A dedicated crock pot or slow cooker provides a low-effort, "set it and forget it" approach, though it will be slower.

- If your primary focus is energy efficiency and you are not in a hurry: A solar oven is a gentle, effective, and eco-friendly option on a sunny day.

Ultimately, mastering the art of melting beeswax is about balancing efficiency with safe, controlled technique.

Summary Table:

| Key Factor | Why It Speeds Up Melting |

|---|---|

| Small Wax Chunks (1-2 inch) | Increases surface area for faster, more even heat absorption. |

| Double Boiler | Provides strong, consistent, indirect heat without dangerous hot spots. |

| Optimal Temperature (143-151°F) | Melts wax quickly while preserving its natural color and scent. |

Need reliable, high-capacity equipment for your beekeeping operation?

As a commercial beekeeper or distributor, you need efficient and safe methods to process wax at scale. HONESTBEE supplies professional-grade beekeeping supplies and equipment through our wholesale-focused operations. We can provide the durable tools you need to melt, filter, and manage beeswax efficiently and safely.

Contact HONESTBEE today to discuss your commercial or wholesale equipment needs and enhance your productivity.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Fully Automatic Beeswax Embossing Machine Foundation Mill

- Beeswax Machine Press Embosser Wax Foundation Mold Printer Bee Hive Equipment Making Sheet

- Silicone Rubber Honey Drum Heating Belt

- HONESTBEE Classic Twist Up Lip Balm Tubes

People Also Ask

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material

- What is the flashpoint of beeswax? Essential Safety and Quality Tips for Beekeepers

- What are the primary products of honey bee farming besides honey? Discover the Hive's Hidden Treasures

- What are the main types of wax melters? Choose the Right Heating Method for Your Needs

- What happens to beeswax if it is heated beyond 170F? Prevent Irreversible Quality Loss and Darkening