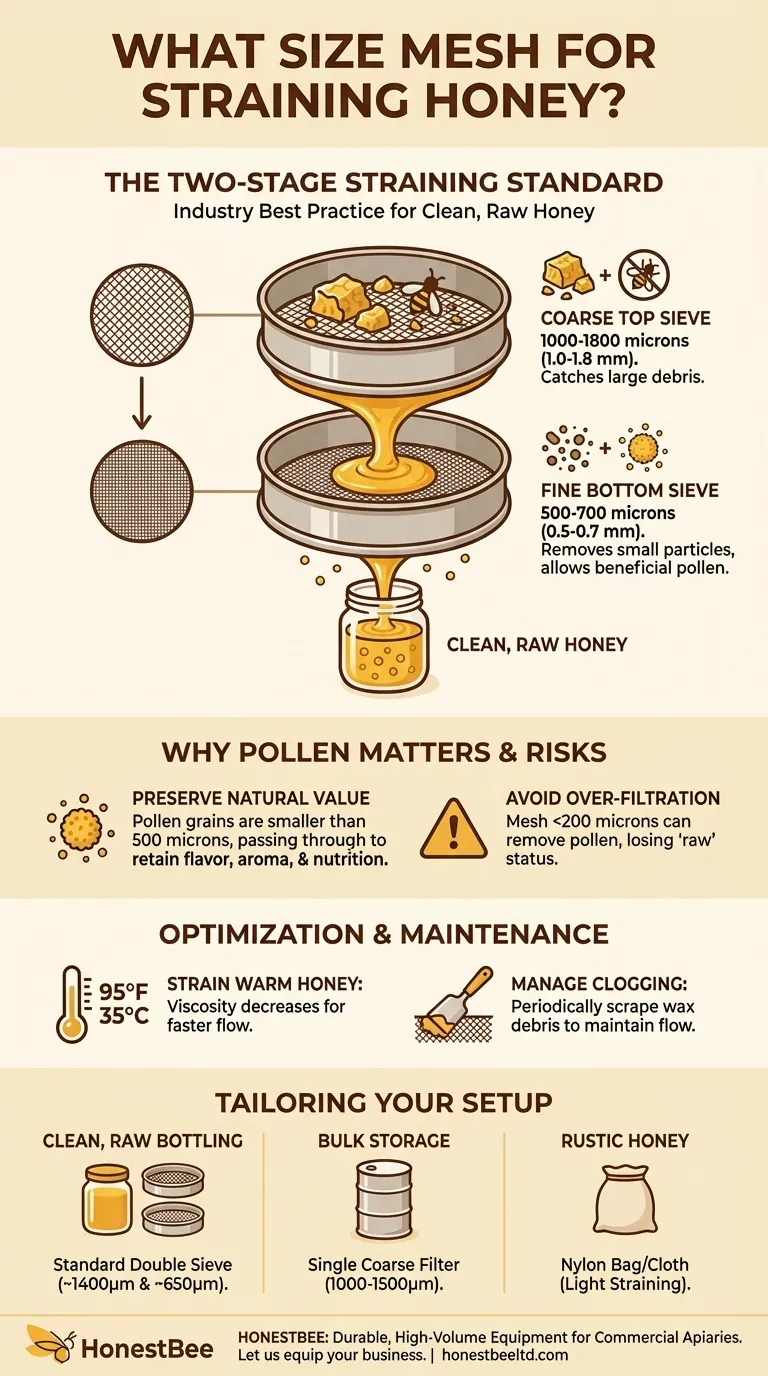

For straining honey, the standard and most effective method uses a two-stage system. This involves a coarse top sieve of around 1000-1800 microns (1.0-1.8 mm) to catch large debris, followed by a finer bottom sieve between 500-700 microns (0.5-0.7 mm) to remove smaller particles. This combination ensures wax and bee parts are removed while allowing beneficial pollen to pass through.

The goal of straining honey isn't to purify it, but to gently remove unwanted debris from the uncapping and extraction process. Using a two-stage mesh system is the industry best practice to clean the honey effectively without stripping it of its natural, beneficial components.

The Two-Stage Straining System Explained

Most honey strainers sold by beekeeping suppliers are double sieves. This design isn't arbitrary; it's a highly efficient system designed to prevent rapid clogging and ensure a clean final product.

The Coarse First Pass (Top Sieve)

The top filter is your first line of defense. Its job is to catch the largest pieces of debris that fall into the honey during extraction.

This includes obvious contaminants like wax cappings, bee parts, and small wood fragments from the frames. The mesh for this stage is typically coarse, ranging from 1000 to 1800 microns.

The Fine Second Pass (Bottom Sieve)

Once the honey passes through the coarse filter, it flows to the finer mesh below. This sieve is designed to catch smaller suspended particles that the top filter missed.

The key is to use a mesh fine enough to catch remaining debris but not so fine that it removes pollen. The ideal range for this stage is 500 to 700 microns.

Why Pollen Size Matters

This two-stage system is specifically designed to preserve the natural pollen content of your honey.

Most pollen grains are much smaller than 500 microns, allowing them to pass through both filters easily. This ensures the final product can still be considered "raw," retaining its unique flavor, aroma, and nutritional profile.

Understanding the Trade-offs

Choosing the right mesh is a balance between cleanliness and preserving the honey's natural character. Going too far in either direction can lead to problems.

The Risk of Over-Filtration

Using a mesh that is too fine (e.g., 200 microns or less) can begin to remove pollen and other microscopic constituents.

This level of filtration is often considered "ultra-filtration" and can legally change the classification of your honey, as it no longer contains the properties of its raw, natural state.

The Impact of Honey Temperature

The viscosity of honey is highly dependent on its temperature. Cold honey is thick and will pass through a strainer very slowly, if at all.

For best results, strain your honey when it is warm, ideally right after extraction when it holds the natural warmth of the hive (around 95°F / 35°C). Straining on a warm day or in a warm room makes the process dramatically easier.

Inevitable Clogging

Even with a perfect two-stage system, the sieves will eventually become clogged with wax particles and debris.

Keep a spatula handy to periodically scrape the collected debris from the mesh surfaces, which will allow the honey to flow freely again.

Making the Right Choice for Your Goal

Your ideal setup depends on what you intend to do with your honey.

- If your primary focus is producing clean, raw honey for bottling: A standard double sieve with a coarse (approx. 1400 micron) and fine (approx. 650 micron) mesh is the perfect tool for the job.

- If your primary focus is a quick, initial strain before bulk storage: A single, coarse filter (1000-1500 microns) may be sufficient to remove the largest debris before you store the honey for later processing.

- If your primary focus is minimally processed, rustic honey: Using a simple nylon straining bag or cloth can provide a very light straining that only removes the most significant debris.

Ultimately, selecting the correct mesh size is the key to producing beautiful, clean honey while preserving its essential natural qualities.

Summary Table:

| Straining Stage | Purpose | Ideal Mesh Size (Microns) | Ideal Mesh Size (mm) |

|---|---|---|---|

| Coarse (Top Sieve) | Removes large debris (wax cappings, bee parts) | 1000 - 1800 | 1.0 - 1.8 |

| Fine (Bottom Sieve) | Removes smaller particles while allowing pollen to pass | 500 - 700 | 0.5 - 0.7 |

Ready to produce clean, high-quality honey efficiently?

As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the durable, industry-standard straining equipment you need to scale your operation. Our two-stage honey strainers are designed for high-volume use, ensuring you can process honey effectively while preserving its raw, marketable qualities.

Let us equip your business for success. Contact our team today to discuss your commercial beekeeping supply needs.

Visual Guide

Related Products

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- Conical Nylon Honey Strainer Filter Bag for Beekeeping and Honey Filtration

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What is a steel strainer used for? A Kitchen Essential for Precision & Hygiene

- Why are dual filtration sieves used in honey processing? Balance Purity & Nutrition for Professional Honey Production

- What is the procedure for managing a brood nest restricted by honey or pollen? Restore Space for Queen Laying

- What is the function of a 0.5mm fine mesh sieve in wild honey? Clean Your Honey While Preserving Enzyme Activity

- What is the function of a plastic double sieve in honey filtration? Ensure Pure, High-Quality Raw Honey Results