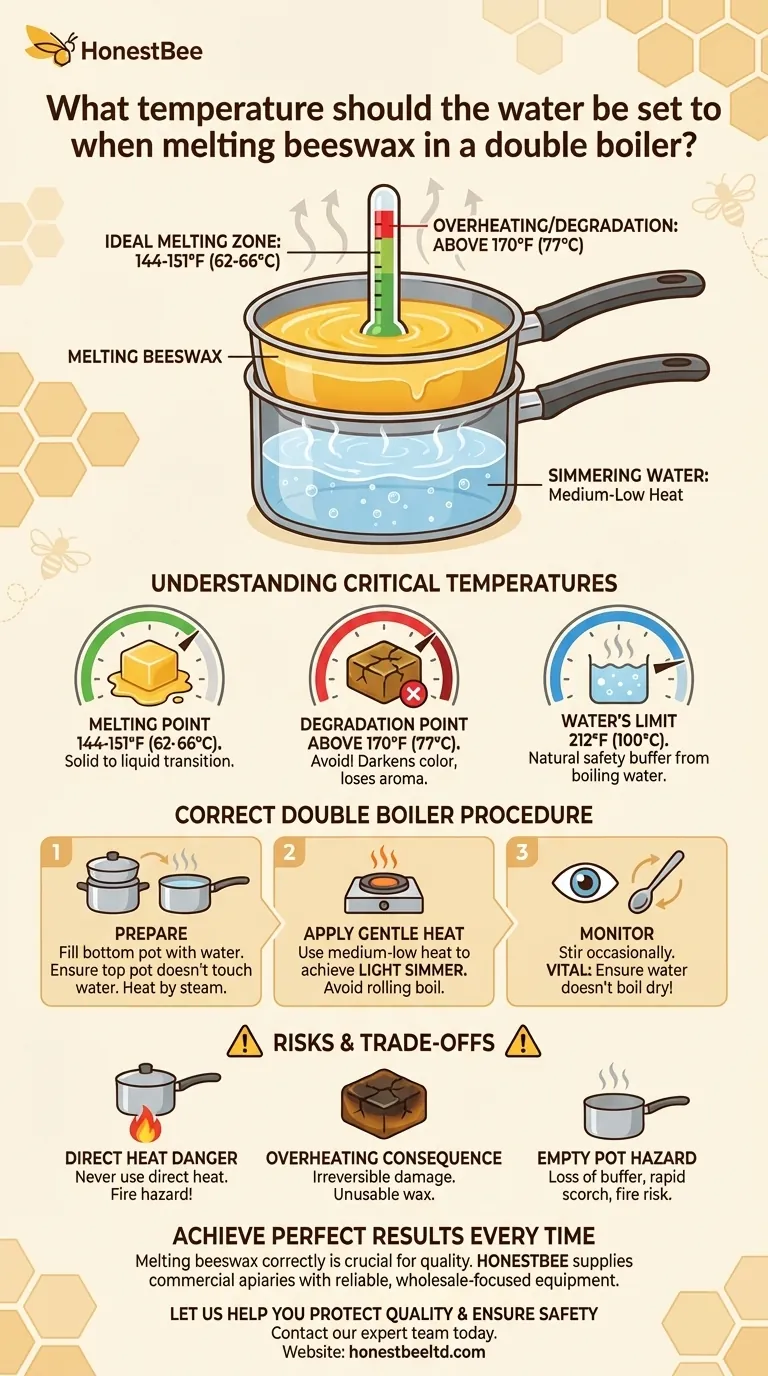

For melting beeswax in a double boiler, the water in the bottom pot should be maintained at a gentle simmer, which corresponds to a medium-low or medium stove setting. The primary goal is not to achieve a specific water temperature, but to use the simmering water as a buffer to gently heat the beeswax above its melting point of 144-151°F (62-66°C) while ensuring the wax itself never exceeds 170°F (77°C).

The core principle is not about heating the wax quickly, but about controlling the heat source. Using simmering water in a double boiler creates a self-regulating system that prevents the wax from scorching, losing its aroma, or reaching its dangerous flashpoint.

Understanding the Critical Temperatures

The key to successfully melting beeswax is understanding three distinct temperature thresholds: the melting point, the degradation point, and the limit of the water itself.

The Melting Point: 144-151°F (62-66°C)

This is the temperature range where solid beeswax transitions into a liquid. Your objective is to bring the wax to this temperature and hold it there until fully melted.

The Degradation Point: Above 170°F (77°C)

This is the temperature you must avoid exceeding. Once beeswax gets hotter than 170°F, it begins to degrade. It will darken in color and lose its subtle, signature honey aroma.

The Water's Limit: 212°F (100°C)

Water boils at 212°F (100°C) at sea level. This physical limit is why a double boiler is so effective. The steam from the water provides indirect heat that cannot, by its nature, go far beyond this temperature, creating a vital safety buffer.

The Correct Double Boiler Procedure

Following a precise method ensures both safety and a quality result. The process is about gentle, indirect heat application.

Step 1: Prepare the Double Boiler

Partially fill the larger, bottom pot with water. Place the smaller pot or heat-proof bowl containing your beeswax on top. Ensure the bottom of the top pot does not touch the water; it should be heated by the rising steam.

Step 2: Apply Gentle Heat

Place the setup on the stove and turn the burner to a medium-low setting. The goal is to bring the water to a light simmer, characterized by small bubbles gently breaking the surface. A vigorous, rolling boil is unnecessary and creates too much steam.

Step 3: Monitor the Process

As the water simmers, the steam will transfer heat to the top pot and melt the wax. Stir the wax occasionally. Most importantly, keep an eye on the water level in the bottom pot to ensure it does not boil dry.

Understanding the Risks and Trade-offs

Using a double boiler mitigates most risks, but improper use can still lead to problems. Understanding these pitfalls is crucial.

The Danger of Direct Heat

Never melt beeswax directly in a pot on a stove. The metal can quickly exceed the wax's degradation point and, more critically, its flashpoint, creating a significant fire hazard. The double boiler method is non-negotiable for safety.

The Consequence of Overheating

If you allow the wax to get too hot (above 170°F / 77°C), the damage is irreversible. For applications like cosmetics or high-quality candles where color and scent are paramount, overheated wax is unusable.

The Hazard of an Empty Pot

The most common mistake is allowing the water in the bottom pot to evaporate completely. When this happens, you lose your temperature buffer. The bottom pot becomes a dry, direct heat source that will rapidly scorch the wax and create a fire risk.

Making the Right Choice for Your Goal

Your specific goal dictates how carefully you need to monitor the temperature.

- If your primary focus is preserving color and aroma for cosmetics: Use the lowest effective heat to maintain a simmer and consider using a thermometer to ensure the wax stays well below 170°F (77°C).

- If your primary focus is safe melting for utility purposes (e.g., waterproofing): A steady simmer on medium-low is sufficient. The main priority is simply not letting the water boil dry.

- If you are a beginner and want maximum safety: Start with low heat and slowly increase it to find the simmer point. Never walk away from melting beeswax.

Ultimately, controlling the heat is about protecting the inherent qualities of the beeswax and ensuring a safe process from start to finish.

Summary Table:

| Critical Temperature | Purpose & Importance |

|---|---|

| Melting Point: 144-151°F (62-66°C) | The temperature at which solid beeswax becomes liquid. |

| Degradation Point: Above 170°F (77°C) | Avoid this temperature to prevent darkening and loss of aroma. |

| Water's Limit: 212°F (100°C) | The double boiler uses simmering water as a safe, self-regulating heat buffer. |

Achieve Perfect Results Every Time

Melting beeswax correctly is crucial for producing high-quality candles, cosmetics, and other products. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the reliable, wholesale-focused supplies needed for professional results. From durable double boilers to precision thermometers, our equipment ensures a safe and efficient process.

Let us help you protect your product's quality and ensure operational safety. Contact our expert team today to discuss your wholesale supply needs.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- What equipment is commonly used for heating and processing honey? Essential Tools for Every Beekeeper

- At what temperature does honey flow? Preserve Quality with the Perfect 95°F Sweet Spot

- What is the water bath method for honey processing? A Gentle Technique for Quality Honey

- How to permanently decrystallize honey? Embrace Its Natural State for Maximum Quality

- What is the effect of heating on honey? Preserve Quality with Controlled Warming