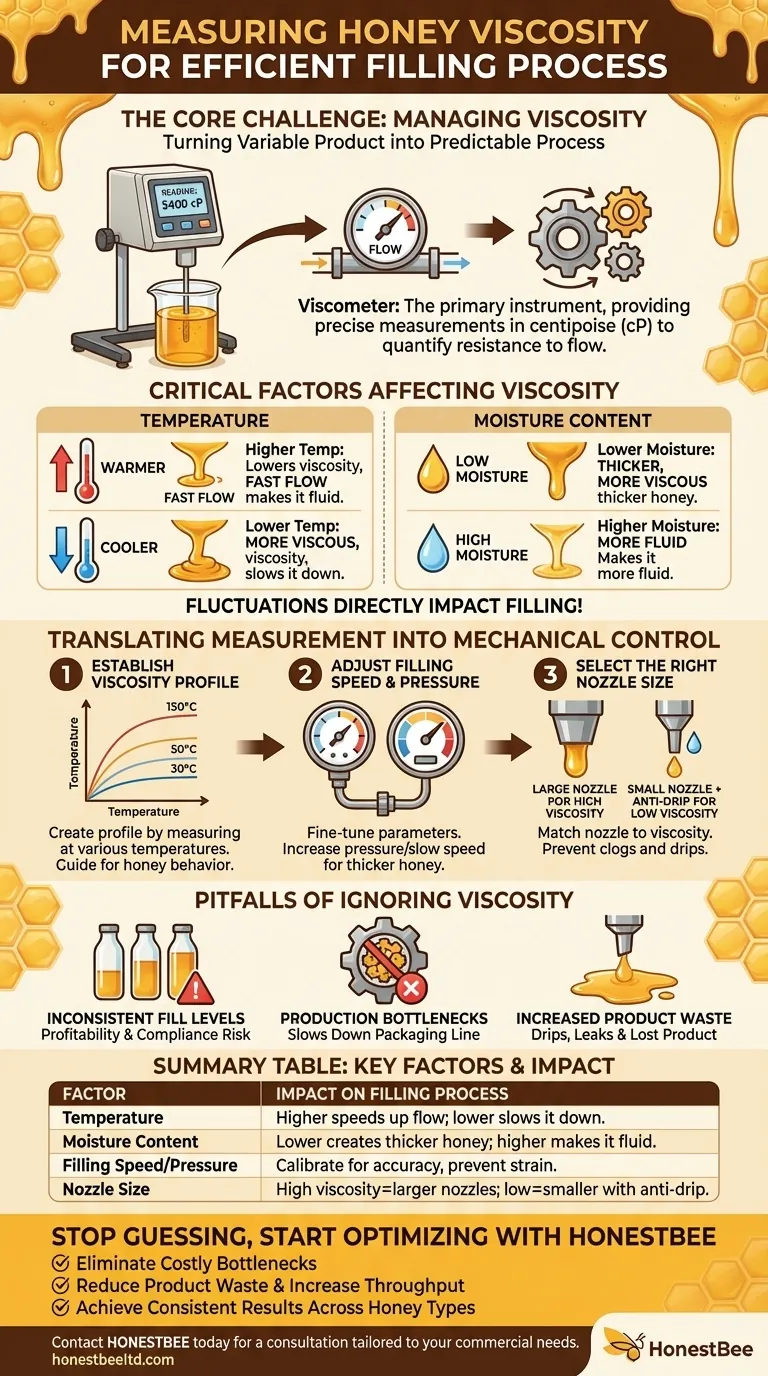

To measure honey viscosity during the filling process, the primary instrument used is a viscometer. This device provides a precise measurement, typically in units called centipoise (cP), which quantifies the honey's resistance to flow. By recording these measurements at different temperatures, operators can accurately calibrate their filling machinery for consistent and efficient performance.

The core challenge in honey filling isn't the liquid itself, but its constantly changing nature. Measuring viscosity is the critical step that allows you to control for these changes, turning a variable product into a predictable and manageable process.

Why Viscosity is the Central Challenge in Honey Filling

The difficulty with packaging honey stems from one key characteristic: its viscosity is not a fixed number. It is a dynamic property that changes based on several environmental and product-specific factors.

The Impact of Temperature

Temperature is the most significant factor affecting honey's viscosity. As honey cools, it becomes thicker and flows more slowly, increasing its viscosity. Conversely, warming honey makes it more fluid and less viscous, allowing it to flow much more easily.

The Role of Moisture Content

Moisture content also plays a crucial role. Honey with a lower moisture content will be thicker and more viscous than honey with a higher moisture content, even at the same temperature.

How Viscosity Affects Machinery

These fluctuations directly impact the filling process. High viscosity can lead to slow fill times, place strain on pumps, and cause machinery to clog. Low viscosity can result in drips, leakage, and inaccurate fill volumes.

Translating Measurement into Mechanical Control

A viscometer provides the data needed to counteract these issues. It allows operators to move from reactive problem-solving to proactive process control.

Establishing a Viscosity Profile

By taking measurements at various temperatures, you can create a viscosity profile for a specific batch of honey. This profile serves as a guide for how the honey will behave under different conditions.

Adjusting Filling Speed and Pressure

With a clear viscosity measurement, you can fine-tune the filling machine's parameters. For thicker, more viscous honey, you may need to increase pump pressure or slow down the filling speed to ensure a complete and accurate fill without over-stressing the equipment.

Selecting the Right Nozzle Size

Viscosity data also informs the choice of equipment. Highly viscous honey requires a larger nozzle size to allow for adequate flow, while less viscous honey can use a smaller nozzle, often equipped with an anti-drip feature to prevent spillage.

Common Pitfalls of Ignoring Viscosity

Failing to properly measure and manage honey viscosity introduces significant inefficiency and cost into the packaging process.

Inconsistent Fill Levels

The most immediate problem is inconsistent product volume. Changes in flow rate due to unmanaged viscosity lead to under-filled or over-filled containers, impacting profitability and regulatory compliance.

Production Bottlenecks

A sudden drop in temperature can cause honey to thicken unexpectedly, dramatically slowing down the entire packaging line. This creates a major bottleneck that reduces overall throughput.

Increased Product Waste

Without proper machine calibration based on viscosity, drips and spills become common. This is especially true for systems not equipped with anti-drip nozzles, leading to lost product and increased cleaning time.

Making the Right Choice for Your Goal

Using a viscometer is the first step. The next is to apply that data to optimize your process based on your specific operational priorities.

- If your primary focus is maximizing speed and throughput: Use viscosity readings to identify the ideal heating temperature that makes the honey fluid enough for rapid filling without becoming too thin and causing drips.

- If your primary focus is precision and minimizing waste: Use viscometer data to perfectly match your filling speed and nozzle configuration to the honey's flow characteristics, relying heavily on anti-drip features.

- If your primary focus is handling diverse honey types: A viscometer is essential for creating a unique operational profile for each floral source, ensuring consistent results across your entire product line.

Ultimately, managing honey viscosity transforms the filling process from a challenge of guesswork into a science of precision and efficiency.

Summary Table:

| Viscosity Factor | Impact on Filling Process |

|---|---|

| Temperature | Higher temps lower viscosity, speeding up flow; lower temps increase viscosity, slowing it down. |

| Moisture Content | Lower moisture creates thicker, more viscous honey; higher moisture makes it more fluid. |

| Filling Speed/Pressure | Must be calibrated based on viscosity to ensure accuracy and prevent equipment strain. |

| Nozzle Size | High viscosity requires larger nozzles; low viscosity needs smaller nozzles with anti-drip features. |

Stop guessing and start optimizing your honey packaging line.

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the robust, wholesale-focused supplies needed for precision filling. Our expertise helps you:

- Eliminate costly bottlenecks and inconsistent fills by understanding your honey's exact viscosity.

- Reduce product waste and increase throughput with the right equipment configurations.

- Achieve consistent results across diverse honey types, from delicate clover to robust wildflower.

Let us provide the durable equipment and expert guidance to turn your filling process into a model of efficiency. Contact HONESTBEE today for a consultation tailored to your commercial needs.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

People Also Ask

- What packaging issues can arise from excess moisture in honey? Prevent Container Failure & Spoilage

- What is the function of the motor in a honey stick machine? Powering Your Honey Stick Production

- How do automated Honey-filling Machines contribute to sustainability? Economic Resilience for Commercial Apiaries

- What role does industrial honey processing and filling machinery play in forest honey? Boost Your Market Value

- In what ways do automated honey-filling machines safeguard purity? Enhance Your API Quality Control

- How does the desired packaging type influence the choice of a honey packaging machine? Match Equipment to Your Format

- How does honey-filling machinery enhance the market value of stingless bee honey? Scale Your Premium Honey Brand

- In what ways do automated honey-filling machines improve the commercial value of urban bee products? Scale Your Brand