Frame making machine

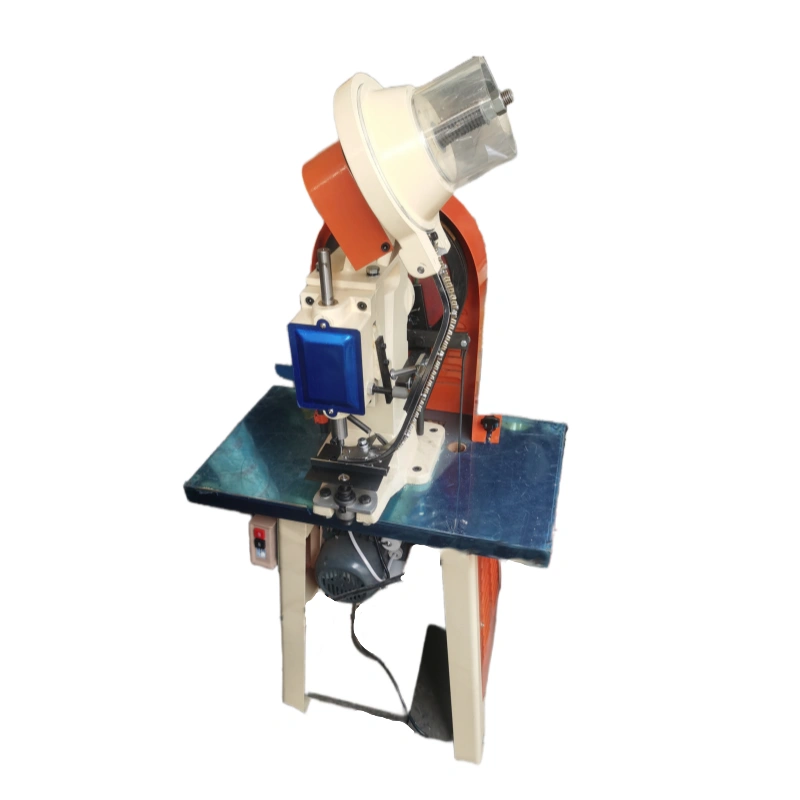

Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

Item Number : BFEM-1

Price varies based on specs and customizations

- Function

- Assemble eyelets into side bar of beehive frames

- Efficiency

- 15 pcs/minute

- Customization

- Available

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

The Bee Frame Eyelets Fitting Machine is a versatile and essential tool designed to cater to various sectors within the beekeeping and agricultural industries. Its primary function is to assemble copper eyelets into the side bars of beehive frames, ensuring the structural integrity and durability of the frames.

Here are some key applications of this machine:

-

Beekeeping Equipment Manufacturers: This machine is perfect for mass-producing durable and reliable bee frames, which are essential for commercial beekeepers. It ensures that each frame is consistently assembled, reducing the risk of hive failures and increasing the longevity of the beekeeping equipment.

-

Agricultural Supply Companies: By incorporating the Bee Frame Eyelets Fitting Machine into their production lines, agricultural supply companies can expand their product offerings with high-quality, machine-assembled bee frames. This not only enhances their product line but also attracts more customers looking for reliable beekeeping solutions.

-

Apiary Maintenance: For apiaries, maintaining long-lasting hive components is crucial. The machine ensures that copper eyelets are securely fitted into the frames, which is essential for the durability and stability of the hives. This reduces the need for frequent replacements and maintenance, saving time and resources.

-

Customization for Specific Needs: The machine can be customized to meet the specific requirements of different production facilities. Whether it's adjusting the speed settings, compatibility with varying eyelet sizes, or integration with other automation tools, the machine offers flexibility to cater to diverse needs.

Feature

The Bee Frame Eyelets Fitting Machine is packed with features that make it a standout choice for beekeeping equipment manufacturers and agricultural supply companies. Here are some of its key features:

-

High-Speed Automation: The machine boasts an impressive output of 15 eyelets per minute, significantly accelerating the production line compared to manual assembly. This high-speed automation ensures that large volumes of bee frames can be produced efficiently.

-

Robust Construction: Built with heavy-duty materials, the machine is designed to withstand continuous operation in demanding environments. This robust construction ensures long-term durability and reliability, reducing the need for frequent maintenance.

-

Precision Engineering: The machine guarantees accurate placement of copper eyelets, which is critical for the structural integrity of bee frames and hive durability. This precision engineering ensures that each frame is assembled to the highest standards.

-

Energy-Efficient Operation: Powered by a 0.37kW single-phase 220V 50Hz motor, the machine is energy-efficient, reducing energy consumption without compromising performance. This makes it a cost-effective and eco-friendly solution for production facilities.

-

Customizable Design: The machine can be tailored to meet specific production needs, including adjustments for frame dimensions, eyelet size, or production speed. This customization ensures that the machine can adapt to different production requirements.

Principle

The Bee Frame Eyelets Fitting Machine operates on a simple yet effective principle designed to streamline the assembly of copper eyelets into bee frame side bars. Here’s a detailed look at its operational principles:

-

Automated Assembly Process: The machine automates the process of inserting copper eyelets into the side bars of beehive frames. This automation replaces the labor-intensive manual process, significantly reducing the time and effort required for assembly.

-

Precision Placement: The machine is equipped with precision engineering components that ensure each eyelet is placed accurately and securely. This precision is crucial for maintaining the structural integrity of the bee frames, which is essential for the durability of the hives.

-

Energy Efficiency: The machine operates on a 0.37kW single-phase 220V 50Hz motor, which is designed to be energy-efficient. This not only reduces operational costs but also minimizes the environmental impact of the production process.

-

Customization Options: The machine can be customized to meet specific production needs, including adjustments for frame dimensions, eyelet size, or production speed. This flexibility allows the machine to adapt to different production requirements, making it a versatile solution for various applications.

Advantage

The Bee Frame Eyelets Fitting Machine offers numerous advantages that make it an invaluable asset for beekeeping equipment manufacturers and agricultural supply companies. Here are some of the key advantages:

-

Cost Savings: The machine significantly reduces labor costs by automating the assembly process. This not only lowers operational expenses but also increases overall productivity, making it a cost-effective solution for high-volume production.

-

Consistent Quality: The machine eliminates human error, ensuring that each bee frame is assembled to the highest standards. This consistent quality enhances the durability and reliability of the beekeeping equipment, leading to increased customer satisfaction.

-

Scalability: The machine can be customized to match the production demands of different facilities, whether it's a small-scale workshop or a large industrial plant. This scalability ensures that the machine can grow with your business, providing a long-term solution for your production needs.

-

Ease of Installation: The machine is designed for easy installation, allowing production facilities to quickly integrate it into their existing production lines. This minimizes downtime and ensures a smooth transition to automated assembly.

-

Environmental Benefits: The machine’s energy-efficient operation reduces energy consumption, making it an eco-friendly choice for production facilities. This not only lowers operational costs but also contributes to a more sustainable production process.

-

Enhanced Safety: The machine is equipped with enhanced safety features to protect operators during the assembly process. This ensures a safe working environment, reducing the risk of accidents and injuries.

Investing in the Bee Frame Eyelets Fitting Machine is a smart choice for any production facility looking to optimize efficiency, reduce costs, and deliver superior-quality bee frames. Contact us today to discuss customization options or place your order – let’s build the future of beekeeping equipment together!

Technical specifications

| Parameter | Specification |

|---|---|

| Function | Assemble eyelets into side bar of beehive frames |

| Voltage | Single phase 220V 50Hz |

| Power | 0.37 kW |

| Efficiency | 15 pcs/minute |

FAQ

What Are The Main Types Of Hole Punchers For Bee Frames?

What Are The Main Applications Of Beekeepers Tools?

What Is A Frame Machine?

What Are The Applications Of Hole Punchers In Beekeeping?

What Are The Advantages Of Using A Bee Frame Making Machine?

What Types Of Tools Are Commonly Used By Beekeepers?

What Are The Main Types Of Frame Machines?

What Are The Advantages Of Using A Hole Puncher For Bee Frames?

What Are The Main Types Of Bee Frame Making Machines?

What Are The Advantages Of Using Beekeepers Tools?

How Does A Frame Punching Hole Puncher Machine Work?

What Are The Applications Of Bee Frame Making Machines?

What Features Should Good Beekeeping Gloves Have?

What Are The Advantages Of Using A Frame Machine?

Why Is Beekeeping Considered A Rewarding Practice?

What Are The Applications Of Frame Machines?

4.8 / 5

This machine is a game-changer for our apiary! The precision and speed are unmatched, saving us so much time.

4.9 / 5

Incredible value for money! The durability and energy efficiency make it a must-have for any beekeeping business.

4.7 / 5

The customization options are fantastic. It fits perfectly into our production line, boosting our output significantly.

4.8 / 5

We’ve seen a huge improvement in frame quality since using this machine. It’s reliable and easy to operate.

4.9 / 5

The high-speed automation is impressive. It’s transformed our production process, making it more efficient than ever.

4.8 / 5

This machine is built to last! The robust construction ensures it can handle heavy use without any issues.

4.7 / 5

The energy-efficient operation is a big plus. It’s eco-friendly and helps us save on electricity costs.

4.9 / 5

Installation was a breeze, and it’s been running smoothly ever since. Highly recommend for any production facility.

4.8 / 5

The precision engineering ensures every frame is perfect. It’s a reliable investment for our business.

4.9 / 5

We’ve cut down on labor costs significantly thanks to this machine. It’s a smart choice for high-volume production.

4.7 / 5

The consistent quality of the frames has improved our beekeeping operations. It’s a fantastic machine.

4.8 / 5

The machine’s scalability is impressive. It’s grown with our business, meeting all our production needs.

4.9 / 5

The enhanced safety features give us peace of mind. It’s a well-designed machine that’s easy to use.

4.7 / 5

We’ve seen a noticeable reduction in maintenance costs. This machine is built to last and perform.

4.8 / 5

The customizable design allows us to adapt it to our specific needs. It’s a versatile and reliable machine.

4.9 / 5

This machine has revolutionized our production process. It’s efficient, reliable, and delivers top-quality frames.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Semi-Auto Bee Frame Assembly and Stapling Machine for Bee Frame

Boost bee frame assembly with our Semi-auto Stapling Machine. High efficiency, customizable options, durable construction. Perfect for beekeeping and honey production.

Mini Desktop Bee Hive Frame Forming Making Machine

Desktop Frame Forming Machine for bee frames, automates Langstroth and Dadant size production efficiently. Explore now!

Multi-Function Frame Grip with Integrated Hive Tool

Frame Grip with Manipulation Tool: Durable stainless steel beekeeping tool for safe frame handling, hive inspections, and honey harvesting. Ergonomic, bee-friendly design.

Electric Flatting and Embossing Machine with Tray for Beekeeping

Flatting and Embossing Machine for beeswax sheets: high efficiency, customizable sizes, and durable aluminum rollers. Ideal for modern beekeeping.

Automatic Honey Frame Uncapper Machine for Beekeeping

Boost honey extraction efficiency with our high-capacity Honey Uncapper Machine. Precision uncapping, durable 304 stainless steel, and customizable frame sizes ensure optimal results. Ideal for large-scale beekeeping operations. Explore now!

Automatic Finger Joints Joint Making Machine for Bee Box and Hive Making

Discover the Finger Joint Bee Box Making Machine, designed for precision and efficiency in hive production. Explore its high-speed output, durable blades, and customizable features for beekeeping needs.

Frame Punching Hole Puncher Machine for Bee Frame Producing Line

Precision Bee Frame Hole Punching Machine for efficient, high-speed production. Ideal for beekeeping supply manufacturers. Customizable and durable.

Copper Bee Frame Eyelets for Beekeeping

Enhance beekeeping with durable copper bee frame eyelets. Protect frames, prevent rust, and ensure hive stability. Ideal for honey extraction.

Queen Bee Artificial Insemination Instrument Equipment for Instrumental Insemination

Enhance bee colony genetics with Instrumental Insemination Equipment. Precise, portable, and cost-effective for beekeepers. Boost hive productivity now!

Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

Electric beeswax flat sheet machine: 750W, stainless steel, 220V. Perfect for beekeepers, ensures uniform wax sheets for honeycomb foundations. Durable, efficient.

Black 2 Pack Beekeeper Queen Grafting Tool for Bee Queen Larva Transferring Needle

Master queen bee rearing with the Black 2 Pack Beekeeper Grafting Tool. Precision, durability, and ease of use for healthy, productive colonies.

Retractable Chinese Queen Rearing Grafting Tools Equipment

Retractable Chinese Queen Rearing Grafting Tools: Precision tools for beekeepers. Gentle larvae handling, easy maintenance, and durable design. Perfect for queen rearing and grafting. Explore now!

Stainless Steel Queen Grafting Tool for Beekeeping and Bee Queen Grafting

Enhance queen rearing with our precision bee grafting tool. Durable, ergonomic, and designed for efficient, gentle larvae transfer. Perfect for beekeepers.

Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

Optimize honey quality with the Honey Dryer, designed for small-scale beekeepers. Efficient, durable, and cost-effective. Explore now!

High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

Enhance honey quality with our Honey Dehumidifier. Advanced technology, 200kg/hour capacity, adjustable temperature, and durable 304 stainless steel. Perfect for beekeepers.

Fully Automatic Honey Filling Packaging Machine for Processing Line

Discover the efficient honey packaging machine for precise, hygienic, and automatic honey filling. Ideal for high-capacity production.

Manual Honey Filling Machine Bottling Machine for Honey

Manual honey filling machine for precise, efficient packaging. Eco-friendly, durable, and customizable for small to medium-scale honey producers.

Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

Boost honey production with our high-capacity Honey Filling Machine. Achieve 1000 bottles/hour, precise filling, and minimal downtime. Enhance brand appeal effortlessly.

Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

Optimize honey packaging with our sachet and filling machines. Ensure purity, efficiency, and precision for all honey types. Upgrade production now!

Related Articles

Unlock Peak Efficiency: The HONESTBEE Bee Frame Machine for Flawless Frame Assembly

Unlock Self-Sufficiency: The HONESTBEE Semi-Automatic Bee Frame Machine – Your All-in-One Workshop Solution

Scaling Up Your Beekeeping Operation: How an HonestBee Bee Frame Machine Fuels Growth

How Beehive Frame Making Machines Enhance Apiary Productivity and Hive Longevity

Discover how beehive frame making machines boost apiary productivity, ensure hive longevity, and save costs for commercial beekeepers.

How to Make Bee Frames in a Factory: The Ultimate Guide to High-Volume Production with HONESTBEE Bee Frame Machines

Revolutionize Your Workshop: The Ultimate Bee Frame Side Bar Forming Machine for Unmatched Efficiency & Customization

How Automated Frame-Making Revolutionizes Beehive Production Efficiency

Discover how automated frame-making boosts beekeeping efficiency with precision grooving, tenon forming, and sustainable materials for healthier hives.

HonestBee Top & Bottom Bar Forming Machine: Precision Manufacturing for Beehive Frames

A specialized wood-forming solution for beehive frame manufacturers offering customizable precision cutting, end-shaping, and notching capabilities to enhance production efficiency.

Engineering Symbiosis: The Unseen Role of the Beeswax Embossing Machine

Discover how beeswax embossing machines create a blueprint for bee productivity, saving colony energy and improving hive management for commercial apiaries.

Are You Choosing the Right Beeswax Embossing Tool? Avoid Common Pitfalls in Foundation Production

Struggling with inconsistent beeswax foundation? Learn why tool choice matters more than you think for commercial apiaries and distributors, and how to optimize your production.

The Physics of a Wasp Sting: Deconstructing Bee Suit Effectiveness

A bee suit's wasp protection depends on material depth and seal integrity to counter the wasp's longer, multi-use stinger.

How Beeswax Foundation Machines and Smart Equipment Transform Beekeeping Efficiency

Discover how beeswax foundation machines and smart beekeeping equipment enhance efficiency, colony health, and honey production for commercial apiaries.