Choosing the right honey packaging machine is critical because honey is a viscous, sensitive product that requires specialized handling. Unlike standard liquids, its thickness demands precise mechanisms to prevent spills, ensure accurate fills, and maintain its purity. The right equipment is not just about efficiency; it's about protecting product integrity and conveying quality from your facility to the consumer's shelf.

Your packaging machine is a guardian of your product's quality and a driver of your operational efficiency. Selecting the wrong one can lead to product waste, inconsistent presentation, and lost revenue, while the right one becomes a cornerstone of your brand's promise.

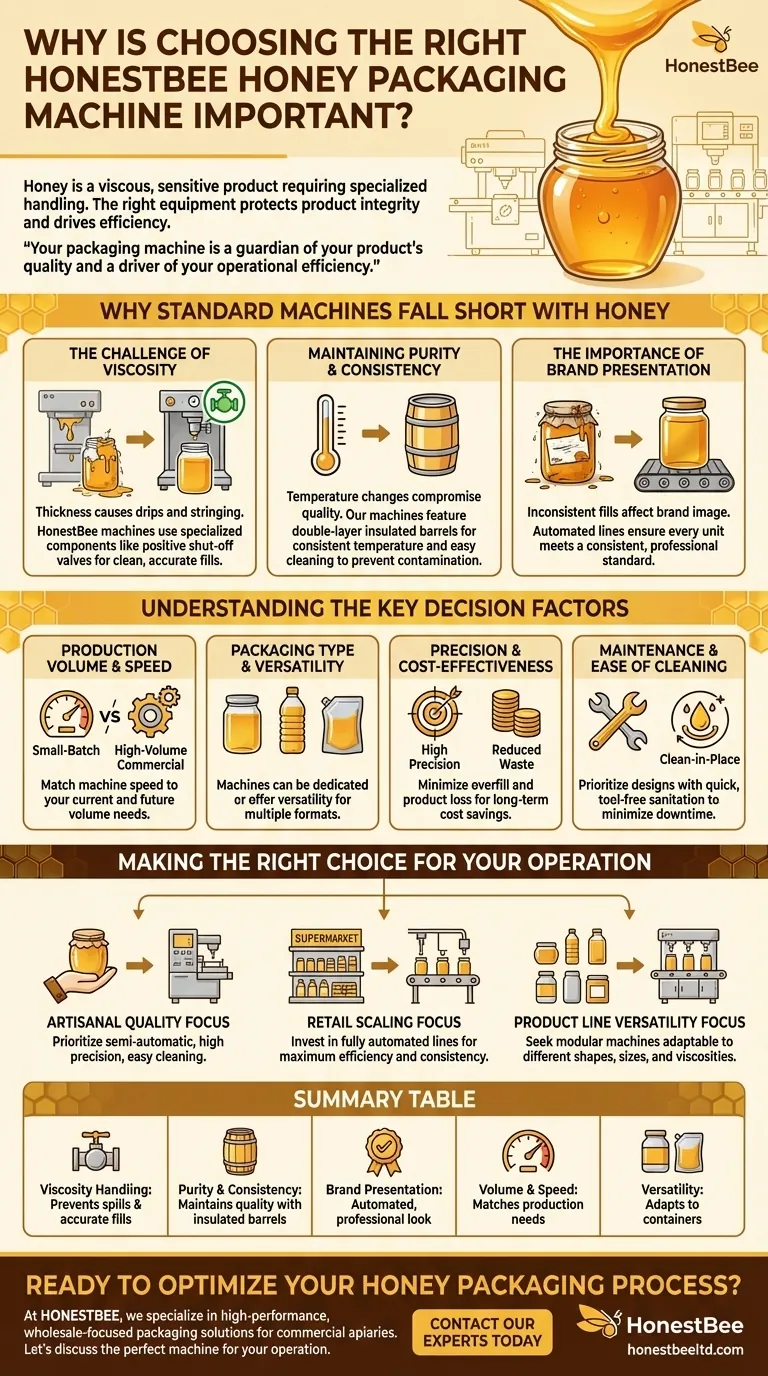

Why Standard Machines Fall Short with Honey

Automated packaging offers clear benefits like increased speed and lower labor costs. However, honey's unique characteristics create specific challenges that generic equipment is not designed to handle.

The Challenge of Viscosity

Honey's thickness, or viscosity, is its primary packaging challenge. It flows slowly and can be difficult to start and stop cleanly.

A proper honey packaging machine uses specialized components, like positive shut-off valves at the filling nozzle, to cut the flow instantly. This prevents dripping and "stringing," ensuring a clean container and an accurate fill volume every time.

Maintaining Purity and Consistency

Honey's quality is defined by its purity and concentration. Contamination or changes in temperature can compromise the final product.

Effective machines address this with features like double-layer insulated barrels. This helps maintain a consistent temperature, ensuring the honey flows smoothly without being overheated. Furthermore, machines designed for food products prioritize ease of cleaning to prevent cross-contamination between batches.

The Importance of Brand Presentation

Your packaging is often the first interaction a customer has with your brand. Inconsistent fill levels, messy drips on the jar, or poorly sealed containers suggest a low-quality product.

A dedicated machine automates the entire process—from conveying containers to filling, sealing, and labeling. This automation ensures that every single unit meets a consistent standard of quality, reinforcing your brand's professional image.

Understanding the Key Decision Factors

Choosing a machine requires a clear-eyed assessment of your operational needs, both now and in the future.

Production Volume and Speed

How many units do you need to package per hour or per day? A small-scale operation has vastly different needs than a large commercial producer. Be realistic about your current volume and projected growth.

Packaging Type and Versatility

Are you packaging in glass jars, plastic bottles, or flexible pouches? Some machines are dedicated to a single container type, while others offer the versatility to handle multiple formats. A machine with a suck-back device, for instance, is crucial for preventing leaks in flexible pouches.

Precision and Cost-Effectiveness

Every drop of wasted honey is lost profit. Look for machines that guarantee high precision and consistency to minimize overfill and product loss. The long-term cost savings from reduced waste can often justify a higher initial investment in a more accurate machine.

Maintenance and Ease of Cleaning

Downtime is a production killer. A machine that is difficult to disassemble and clean will slow down your operation, especially when switching between different types of honey. Prioritize designs that allow for quick, tool-free sanitation.

Making the Right Choice for Your Operation

The ideal machine is the one that best aligns with your specific business goals. Use these points as a guide to frame your decision.

- If your primary focus is small-batch, artisanal quality: Prioritize a semi-automatic machine with exceptional filling precision and simple, tool-free cleaning, even if its overall speed is lower.

- If your primary focus is scaling for retail distribution: Invest in a fully automated line with integrated conveying, filling, sealing, and labeling to maximize efficiency and per-unit consistency.

- If your primary focus is product line versatility: Seek a modular machine that can be adapted for different container shapes, sizes, and honey viscosities, accepting a potentially higher upfront cost for future flexibility.

By carefully matching the machine's capabilities to your operational needs, you ensure your packaging process is a strength, not a bottleneck.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| Viscosity Handling | Prevents spills and ensures accurate fills with positive shut-off valves. |

| Purity & Consistency | Maintains product quality with insulated barrels and easy cleaning. |

| Brand Presentation | Automates processes for a professional, consistent look on every unit. |

| Volume & Speed | Matches your production needs, from small-batch to high-volume operations. |

| Versatility | Adapts to different containers (jars, bottles, pouches) for flexibility. |

Ready to optimize your honey packaging process?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with high-performance, wholesale-focused packaging solutions. Our machines are engineered to handle honey's unique challenges, ensuring precision, reducing waste, and protecting your brand's quality.

Let's discuss the perfect machine for your operation. Contact our experts today for a tailored solution that boosts your efficiency and profitability.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- How does a Volumetric Filling Machine work to ensure consistency? Master Precision with Piston Technology

- How do professional honey filling and packaging machines benefit commercial honey sales? Scale Your Brand for Profit

- What does the honey packaging process in a factory typically involve? A Step-by-Step Guide to Quality Honey Production

- What is the importance of versatility and adaptability in a honey packaging machine? Future-Proof Your Production

- How does a semi-automatic filling machine operate? Boost Your Production Consistency

- What is the function of an automatic honey-filling machine in maintaining export-grade quality?

- How does automated honey sampling and filling equipment assist in safety evaluations? Ensure Lab-Grade Data Integrity

- In what ways do specialized honey packaging and bottling machines affect the economic efficiency of large-scale apiaries?