In short, robust customer support is your primary defense against costly production downtime. A honey filling machine is a critical asset in your operation, and any malfunction, calibration issue, or need for a replacement part can bring your entire bottling process to a halt. Effective support from your supplier ensures that these inevitable issues are resolved quickly, minimizing financial losses and operational disruption.

A honey filling machine is more than a piece of equipment; it's a core component of your production line. Therefore, evaluating a supplier's customer support is as critical as evaluating the machine's technical specifications. Think of support not as an add-on, but as an essential feature that guarantees the machine's long-term value and uptime.

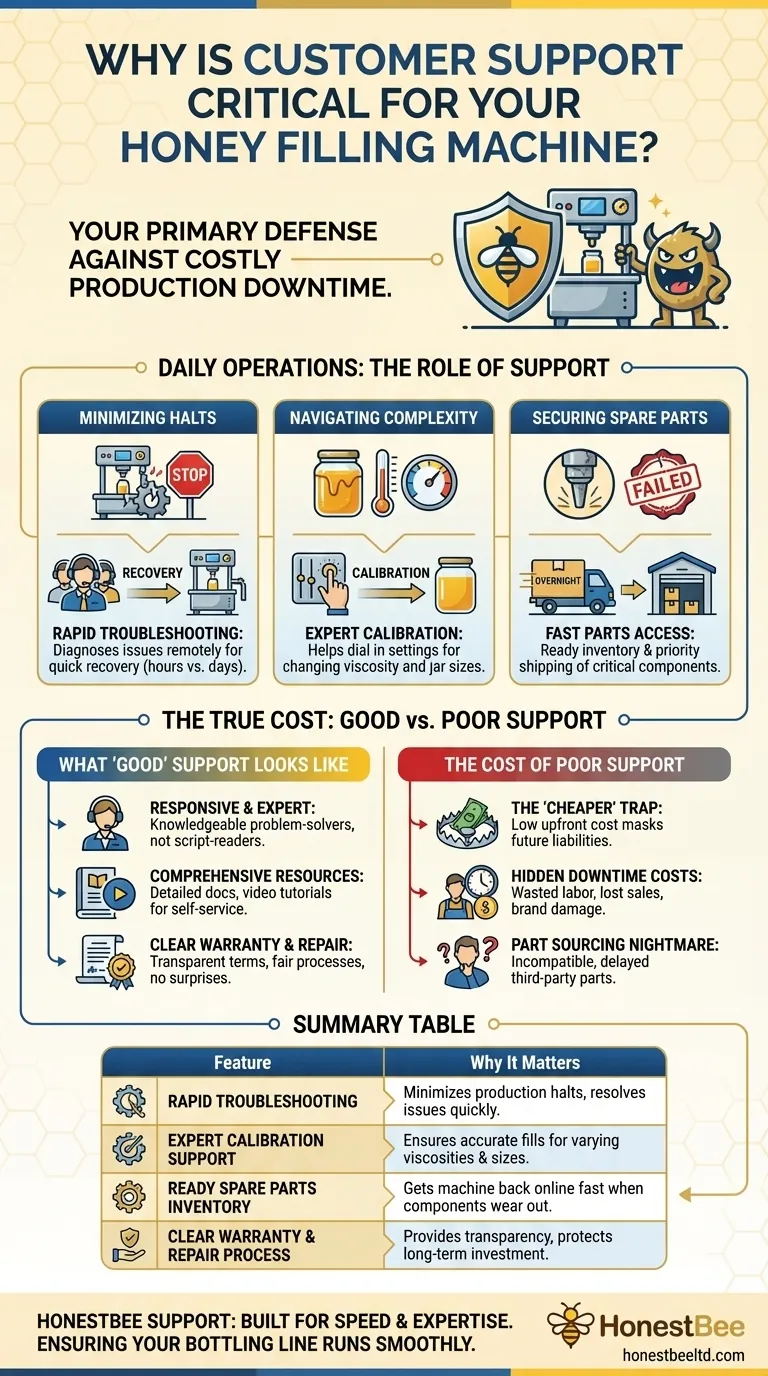

The Role of Support in Daily Operations

Purchasing the machine is only the first step. The real test of its value comes during day-to-day use, where technical and operational challenges are a certainty. Strong support is what turns those challenges from a crisis into a manageable task.

Minimizing Production Halts

Every hour your filling machine is down, you are losing revenue and potentially failing to meet order deadlines. The single most important function of customer support is to provide rapid troubleshooting and solutions.

Whether it's a software glitch, a mechanical failure, or an unexpected error, a responsive support team can diagnose the issue remotely or guide your staff through a fix, getting you back online in hours instead of days.

Navigating Operational Complexity

Honey is a unique product. Its viscosity changes with temperature and floral source, which can require frequent adjustments to the machine's filling parameters.

Good customer support provides the expertise needed for initial setup and ongoing calibration. They can help you dial in the correct settings for different jar sizes, product viscosities, and fill speeds, ensuring both accuracy and efficiency.

Securing the Lifeline: Spare Parts

All machines have components that wear out over time. A simple broken nozzle, seal, or motor can render a machine useless.

A supplier with a strong support system maintains a ready inventory of spare parts and can ship themPriority Mail overnight. Without this, you could face weeks or even months of downtime while trying to source a compatible part on your own.

What "Good" Customer Support Actually Looks Like

Not all support is created equal. Vague promises of "after-sales service" are meaningless without a clear structure. When evaluating a supplier, look for these specific indicators of quality support.

Responsiveness and Expertise

The support team should be easily accessible, with clear hours of operation. More importantly, they must possess deep technical knowledge of their own equipment. The person on the other end of the line should be able to do more than read a script; they should be a problem-solver.

Comprehensive Documentation and Training

The best suppliers empower you to solve minor issues yourself. They provide detailed manuals, video tutorials, and clear documentation for routine maintenance and troubleshooting. This proactive approach saves everyone time.

A Clear Warranty and Repair Process

Understand the warranty terms completely. Does it cover parts and labor? What is the process for a repair? Do you have to ship the machine back, or will they send a technician? A transparent and fair repair process is a hallmark of a reputable company.

Understanding the Trade-offs: The Cost of Poor Support

Often, machines with lower upfront costs achieve that price point by cutting corners on support infrastructure. This is a dangerous trade-off that can cost you far more in the long run.

The "Cheaper" Machine Trap

A machine from a supplier with a weak support system is a significant liability. The initial savings are quickly erased by the first major incident that causes extended downtime. The true cost of a machine is its purchase price plus the cost of any lost production.

Hidden Costs of Downtime

The financial impact of a non-functional filler goes beyond lost sales. It includes wasted labor costs as employees stand by, potential damage to your brand's reputation from unfulfilled orders, and the immense frustration of trying to solve a technical problem without expert help.

The Nightmare of Sourcing Parts

Without a direct line to the manufacturer for certified parts, you are left to navigate a complex market of third-party suppliers. This introduces risks of incompatibility, lower quality, and significant delays, all while your production remains at a standstill.

How to Evaluate Support Before You Buy

To make an informed decision, you must actively investigate a supplier's support system.

- If your primary focus is a small-scale or startup operation: Look for suppliers with excellent documentation, a library of video tutorials, and responsive email or phone support for self-service problem-solving.

- If your primary focus is large-scale, continuous production: Prioritize suppliers who offer formal service-level agreements (SLAs), dedicated support contacts, and options for rapid, on-site repair to maximize uptime.

- If your primary focus is versatility for multiple products: Confirm the support team has proven expertise in helping customers calibrate the machine for different container sizes and product viscosities, like honey versus jam.

Ultimately, you are not just buying a machine; you are investing in a production capability and a long-term partnership with the supplier who supports it.

Summary Table:

| Support Feature | Why It Matters for Your Honey Filler |

|---|---|

| Rapid Troubleshooting | Minimizes production halts by quickly resolving mechanical or software issues. |

| Expert Calibration Support | Ensures accurate fills for varying honey viscosities and container sizes. |

| Ready Spare Parts Inventory | Gets your machine back online fast when critical components wear out. |

| Clear Warranty & Repair Process | Provides transparency and protects your investment in the long term. |

Don't let downtime disrupt your honey production. At HONESTBEE, we understand that a honey filling machine is the heart of your operation. That's why our customer support for commercial apiaries and distributors is built for speed and expertise, ensuring your bottling line runs smoothly. We provide rapid technical assistance, expert calibration guidance, and priority access to genuine spare parts. Contact our team today to discuss your needs and discover how our wholesale-focused support guarantees your productivity.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- How do specialized honey-filling machines contribute to the processing stage? Elevate Your Branding and Hygiene

- What role do honey-filling machines play in the commercialization of wild honey? From Raw Harvest to Global Retail

- What is the process of a sachet filling machine? Optimize Your Packaging Line for Accuracy & Speed

- What are the different types of honey stick machines based on automation? Choose the Right Model for Your Apiary's Scale

- What role do automated honey filling machines play in the honey value chain? Elevate Your Apiary's Commercial Success

- What is the function of an automatic honey-filling machine in maintaining export-grade quality?

- How do honey filtration and filling machinery contribute to industrialization? Scale Your Commercial Honey Production

- What is a filling machine used for? Automate Your Production for Speed and Accuracy