For commercial apiaries prioritizing honey purity and operational efficiency, screw press extraction outperforms centrifugal methods—especially with crystallized or viscous honey varieties. Here's how this compact technology preserves product quality while creating profitable byproducts.

How Honey Screw Presses Work

The Mechanics of Wax-Honey Separation

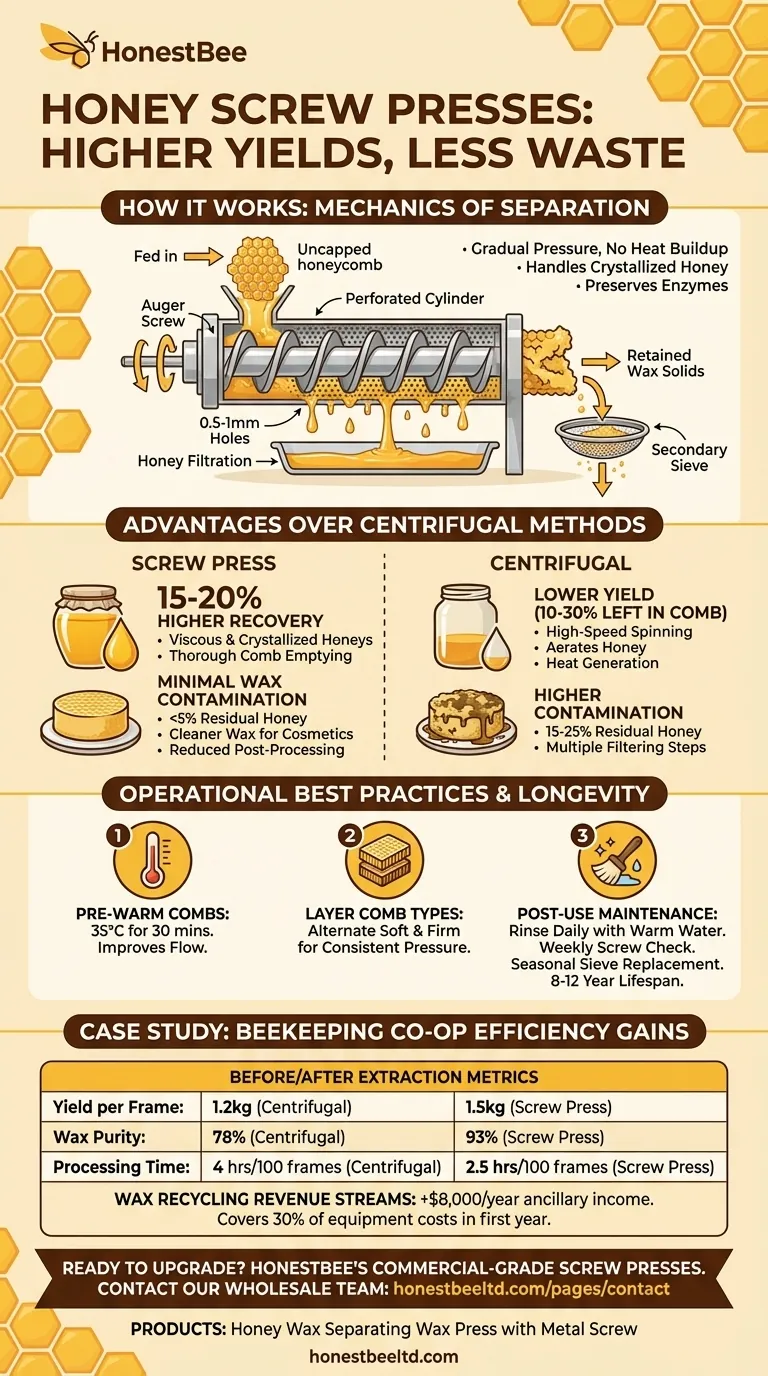

Screw presses apply gradual pressure to uncapped honeycomb, forcing honey through a perforated cylinder while retaining wax solids. Unlike centrifugal extractors that rely on high-speed spinning, this method:

- Prevents heat buildup that can degrade delicate honey enzymes

- Handles crystallized honey without requiring liquefaction

- Separates wax more cleanly for higher-grade byproducts

Key Components: Screw, Cylinder, and Sieve Synergy

- Auger Screw: Slowly compresses comb with adjustable pressure settings

- Perforated Cylinder: Filters honey through 0.5-1mm holes while trapping wax

- Secondary Sieve: Removes residual particulates for bottling-ready honey

Research shows this staged filtration preserves polyphenol levels better than centrifugal methods that can aerate honey during extraction.

Advantages Over Centrifugal Extraction

Higher Yield Rates in Viscous Honeys

Screw presses achieve approximately 15-20% greater recovery with:

- Thixotropic honeys (e.g., manuka, heather)

- Partially crystallized batches

- Comb with higher wax-to-honey ratios

The slow pressing action thoroughly empties comb cells that centrifugal force might leave 10-30% full.

Minimizing Wax Contamination

Centrifugal extraction often requires multiple filtering steps to remove wax flakes. Screw presses:

- Produce wax with under 5% residual honey (vs. 15-25% in centrifugal)

- Yield cleaner wax cakes ideal for cosmetics or candles

- Reduce post-processing labor by up to 40%

Beekeepers report this creates an additional $2-5 revenue per kg of wax compared to lower-quality centrifugal byproducts.

Operational Best Practices

Preventing Clogs in Perforated Cylinders

- Pre-warm Combs: 30 minutes at 35°C improves flow without damaging enzymes

- Layer Comb Types: Alternate soft and firm combs for consistent pressure

- Monitor Output: Clear wax buildup when flow drops by >20%

Post-Use Maintenance for Longevity

- Daily: Rinse with warm (not hot) water to preserve food-grade seals

- Weekly: Inspect screw threads for comb residue

- Seasonally: Replace nylon sieves showing wear

Properly maintained units last 8-12 years—twice the lifespan of centrifugal extractors in commercial settings.

Case Study: Beekeeping Co-op Efficiency Gains

A 300-hive operation switching to screw presses documented:

Before/After Extraction Metrics

| Metric | Centrifugal | Screw Press |

|---|---|---|

| Yield per Frame | 1.2kg | 1.5kg |

| Wax Purity | 78% | 93% |

| Processing Time | 4 hrs/100 frames | 2.5 hrs/100 frames |

Wax Recycling Revenue Streams

The co-op now supplies cosmetic-grade wax to local artisans, adding $8,000/year in ancillary income—covering 30% of equipment costs in the first year.

Ready to upgrade your extraction process? HONESTBEE's commercial-grade screw presses help beekeeping distributors and large apiaries maximize yields while producing premium wax byproducts. Contact our wholesale team for volume pricing on systems designed for 200+ hive operations.

Products You Might Be Looking For:

Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

Visual Guide

Related Products

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

Related Articles

- Beyond the Extractor: How Honey Presses Turn Waste into Profit for Commercial Apiaries

- Essential Beekeeping Tools: How Strategic Preparation Boosts Hive Health, Safety, and Honey Yields

- The Beekeeper's Dilemma: The Brutal, Beautiful Logic of the Honey Press

- Electric Wax Melters: How Modern Technology Enhances Efficiency and Savings

- Is Your Honey Press Underperforming? The Overlooked Secret to Maximizing Your Yield