Whether you're a hobbyist or a commercial beekeeper, selecting the right beeswax uncapping tool can significantly impact your honey yield and operational efficiency. This guide breaks down the key considerations—from manual vs. electric tools to long-term cost factors—so you can make an informed decision tailored to your apiary’s scale and goals.

Understanding Beeswax Capping Removal

Beeswax cappings seal honeycomb cells, preserving the honey until harvest. Removing these cappings cleanly is critical to extracting honey without damaging the comb, which bees must rebuild if compromised. The right tool balances precision, speed, and ease of use.

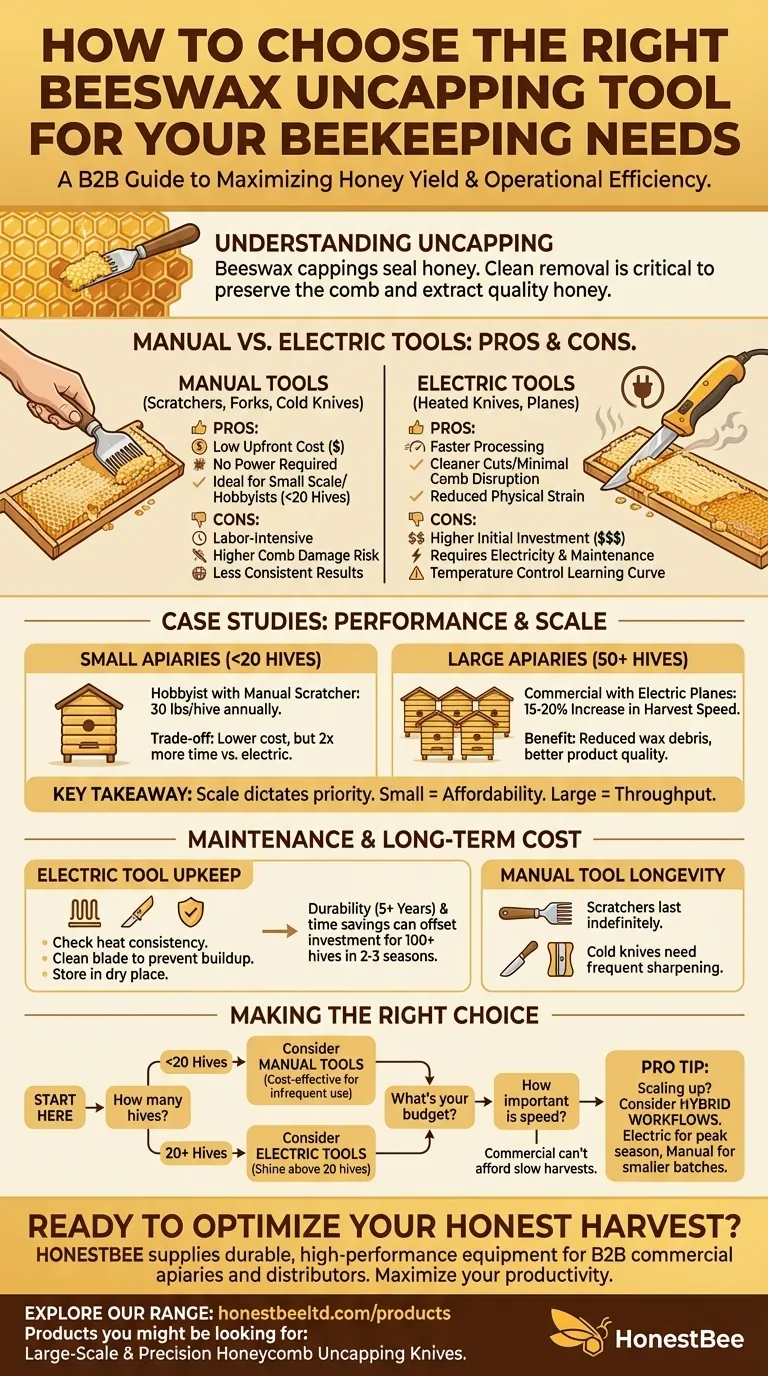

Manual vs. Electric Tools: Pros and Cons

Manual Uncapping Tools (e.g., Scratchers, Forks, Cold Knives)

- Pros:

- Low upfront cost

- No power or heating required

- Ideal for small-scale beekeepers or occasional use

- Cons:

- Labor-intensive and time-consuming

- Higher risk of comb damage

- Less consistent results

Electric Uncapping Tools (e.g., Heated Knives, Planes)

- Pros:

- Faster processing, especially for large batches

- Cleaner cuts with minimal comb disruption

- Reduced physical strain

- Cons:

- Higher initial investment

- Requires electricity and maintenance

- Learning curve for temperature control

Research shows electric tools are favored by commercial apiaries, where efficiency directly correlates with profitability. For hobbyists with under 20 hives, manual tools may suffice.

Case Studies: Tool Performance in Small and Large Apiaries

Small Apiaries (

A hobbyist using a manual scratcher reported harvesting about 30 lbs of honey per hive annually but noted the process took twice as long compared to neighbors using heated knives. The trade-off? Lower equipment costs but higher time investment.

Large Apiaries (50+ Hives)

A commercial beekeeper switched from cold knives to electric uncapping planes and saw a 15–20% increase in harvest speed. The heated blade reduced wax debris in extracted honey, improving product quality for wholesale buyers.

Key Takeaway: Scale dictates priority. Small operations value affordability; large operations prioritize throughput.

Maintenance and Long-Term Cost Considerations

Electric Tool Upkeep

- Heating Elements: Regularly check for consistent heat distribution to avoid uneven cuts.

- Blade Care: Clean after each use to prevent wax buildup, which can dull the blade.

- Safety: Store in a dry place to protect electrical components.

While electric tools cost more upfront, their durability (often 5+ years with proper care) and time savings can offset the investment. For example, a beekeeper harvesting 100+ hives yearly might recoup the cost of an electric knife in 2–3 seasons through labor savings.

Manual Tool Longevity

- Scratchers and forks last indefinitely but may require replacement due to bending or rust.

- Cold knives need frequent sharpening to maintain effectiveness.

Making the Right Choice for Your Apiary

Ask yourself:

- How many hives do I manage? Electric tools shine above 20 hives.

- What’s my budget? Manual tools are cost-effective for infrequent use.

- How important is speed? Commercial beekeepers can’t afford slow harvests.

Pro Tip: If you’re scaling up, consider hybrid workflows—use electric tools for peak season and manual backups for smaller batches.

Ready to Optimize Your Honey Harvest?

HONESTBEE supplies durable, high-performance beekeeping equipment tailored to commercial apiaries and distributors. Whether you need electric uncapping knives for large-scale efficiency or manual tools for precision, our wholesale-focused solutions help you maximize productivity. Explore our range to find the perfect fit for your operation.

Final Thought: The best tool isn’t just about price—it’s about how seamlessly it integrates into your beekeeping workflow, saving you time and preserving your honey’s quality.

Products You Might Be Looking For:

View large-scale beekeeping uncapping tools

Explore precision honeycomb uncapping knives

Visual Guide

Related Products

- Stainless Steel Dual Blade Uncapping Plane

- Professional Compact Multi-Function Uncapping Knife for Beekeeping

- Professional Honey Uncapping Fork Tool with Customizable Tine Options

- Professional Honey Uncapping Roller for Efficient Harvesting

- Professional Honey Scraper for Efficient Apiary Maintenance

Related Articles

- Hot Knife vs. Heat Gun: How Beekeepers Can Optimize Uncapping Efficiency

- Why Uncapped Honeycombs Demand Caution: Science-Based Beekeeping Practices

- Comprehensive Guide to Uncapping Honey Frames for Beekeepers

- How to Uncap Wax Like a Pro: Maximizing Honey Yield While Protecting Your Combs

- The Bottleneck in the Honey House: Choosing the Right Uncapping Tool for Your Scale