Selecting the ideal honey extractor isn’t just about upfront costs—it’s about aligning equipment with your apiary’s size, labor capacity, and growth trajectory. Whether you’re a hobbyist or managing a commercial operation, this guide breaks down efficiency trade-offs, scaling thresholds, and future-proofing strategies to maximize your investment.

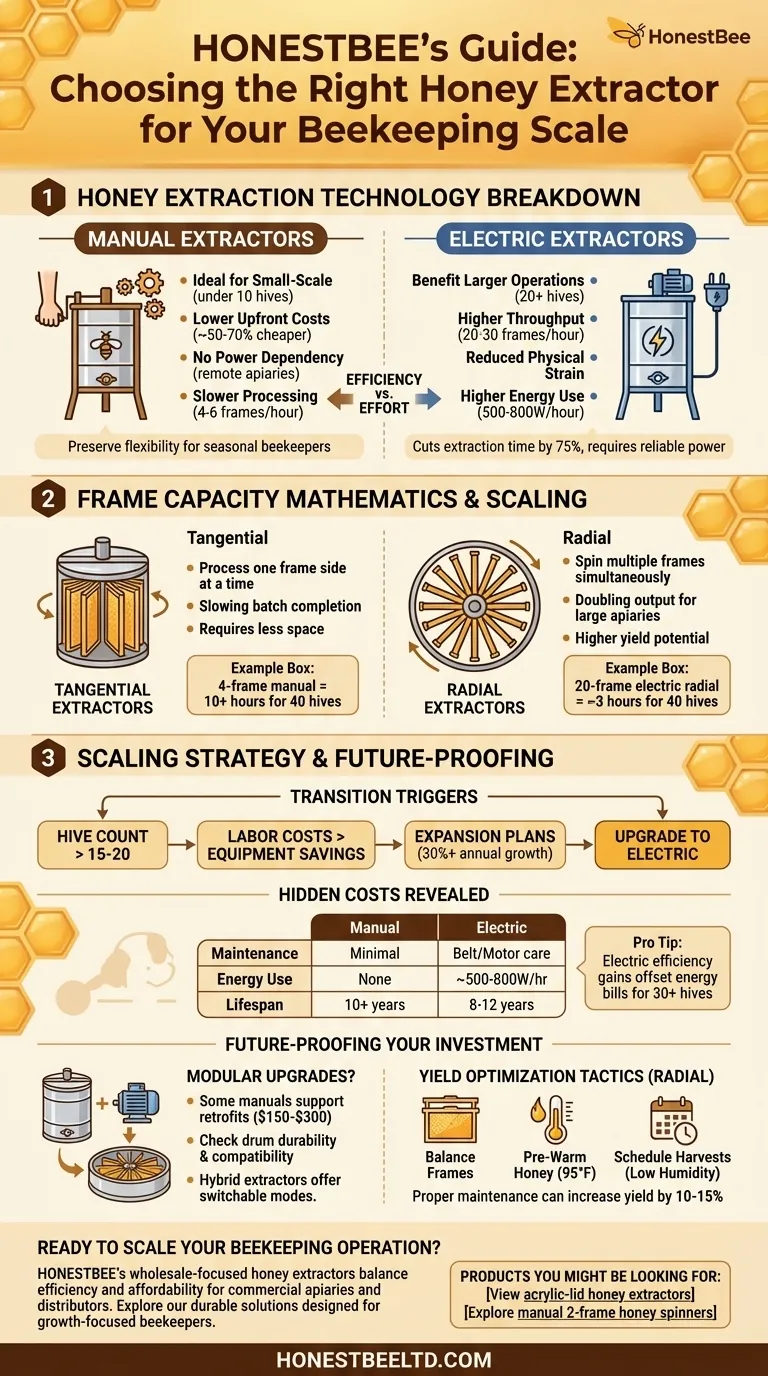

Honey Extraction Technology Breakdown

Labor vs Automation: Physical Effort Benchmarks Across Extractor Types

Manual Extractors suit small-scale beekeepers (under 10 hives) with:

- Lower upfront costs (approximately 50–70% cheaper than electric models)

- No power dependency, ideal for remote apiaries

- Slower processing: Extracts ~4–6 frames per hour due to hand-crank operation

Electric Extractors benefit larger operations through:

- Higher throughput: Processes 20–30 frames hourly with motorized spinning

- Reduced physical strain, critical for frequent harvests

- Higher energy use, requiring reliable power access

Key Consideration: Research shows electric models cut extraction time by 75%, but manual options preserve flexibility for seasonal beekeepers.

Frame Capacity Mathematics: How Design Impacts Batch Processing Speed

Extractor sizing hinges on frame capacity (typically 2–120 frames) and drum type:

- Tangential Extractors: Process one frame side at a time, slowing batch completion but requiring less space

- Radial Extractors: Spin multiple frames simultaneously, doubling output for large apiaries

Example: A 20-frame radial electric extractor completes a 40-hive harvest in ~3 hours, while a 4-frame manual system needs 10+ hours.

Scaling Strategy Alignment

Transition Triggers: Apiary Size Thresholds for Each Extractor Class

Upgrade to electric when:

- Hive count exceeds 15–20, making manual extraction impractical

- Labor costs outweigh equipment savings (e.g., hiring help for harvests)

- Expansion plans anticipate 30%+ annual hive growth

Hidden Cost Alert: Manual extractors may seem economical, but their slower speed risks honey crystallization in delayed processing.

Hidden Costs Revealed: Maintenance & Energy Draw Comparisons

| Factor | Manual Extractors | Electric Extractors |

|---|---|---|

| Maintenance | Minimal (no motor parts) | Belt replacements, motor care |

| Energy Use | None | ~500–800W per hour |

| Lifespan | 10+ years with lubrication | 8–12 years with upkeep |

Pro Tip: Electric models’ efficiency gains often offset higher energy bills for apiaries with 30+ hives.

Future-Proofing Your Investment

Modular Upgrades: Can Manual Extractors Be Motorized Later?

Some manual models support retrofit kits (~$150–$300) to add motors, but check:

- Drum durability: Older units may warp under higher RPMs

- Compatibility: Kits fit only specific brands and frame capacities

Alternative: Hybrid extractors offer switchable manual/electric modes, bridging transitional phases.

Yield Optimization Tactics for Radial Systems

Maximize electric radial extractors by:

- Balancing frames evenly to prevent motor strain

- Pre-warming honey (to 95°F) for smoother flow

- Scheduling harvests during low-humidity periods to reduce stickiness

Did You Know? Properly maintained radial systems can increase yield by 10–15% through thorough comb drainage.

Ready to Scale Your Beekeeping Operation?

HONESTBEE’s wholesale-focused honey extractors balance efficiency and affordability, helping commercial apiaries and distributors streamline harvests. Explore our durable solutions designed for growth-focused beekeepers.

Final Thought: The right extractor acts as a silent partner—whether it’s the simplicity of a hand-crank or the hum of a motor powering your honey’s journey from hive to table.

Products You Might Be Looking For:

View acrylic-lid honey extractors

Explore manual 2-frame honey spinners

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

Related Articles

- Tangential vs Radial Honey Extractors: How to Choose for Your Beekeeping Needs

- The Extractor's Edge: Why Preserving Comb is the Key to Apiary Profitability

- Honey Press vs. Extractor: Why Your Choice Defines Your Apiary's Profitability

- How to Optimize Centrifugal Honey Extraction for Different Hive Types

- How Automatic Honey Extractors Cut Costs and Boost Scalability for Commercial Beekeepers