At their core, honey filling machines ensure product quality by applying engineered control over three critical factors: fill volume, product integrity, and hygiene. They replace manual inconsistencies with mechanical precision, creating a repeatable, contamination-free process from the holding tank to the sealed container. This systematic approach guarantees a consistent and pure product for the end consumer.

The true value of a honey filling machine is not just in its speed, but in its ability to protect the honey's natural characteristics. By precisely managing viscosity, eliminating contamination, and ensuring exact fill levels, these machines act as guardians of your product's quality and your brand's reputation.

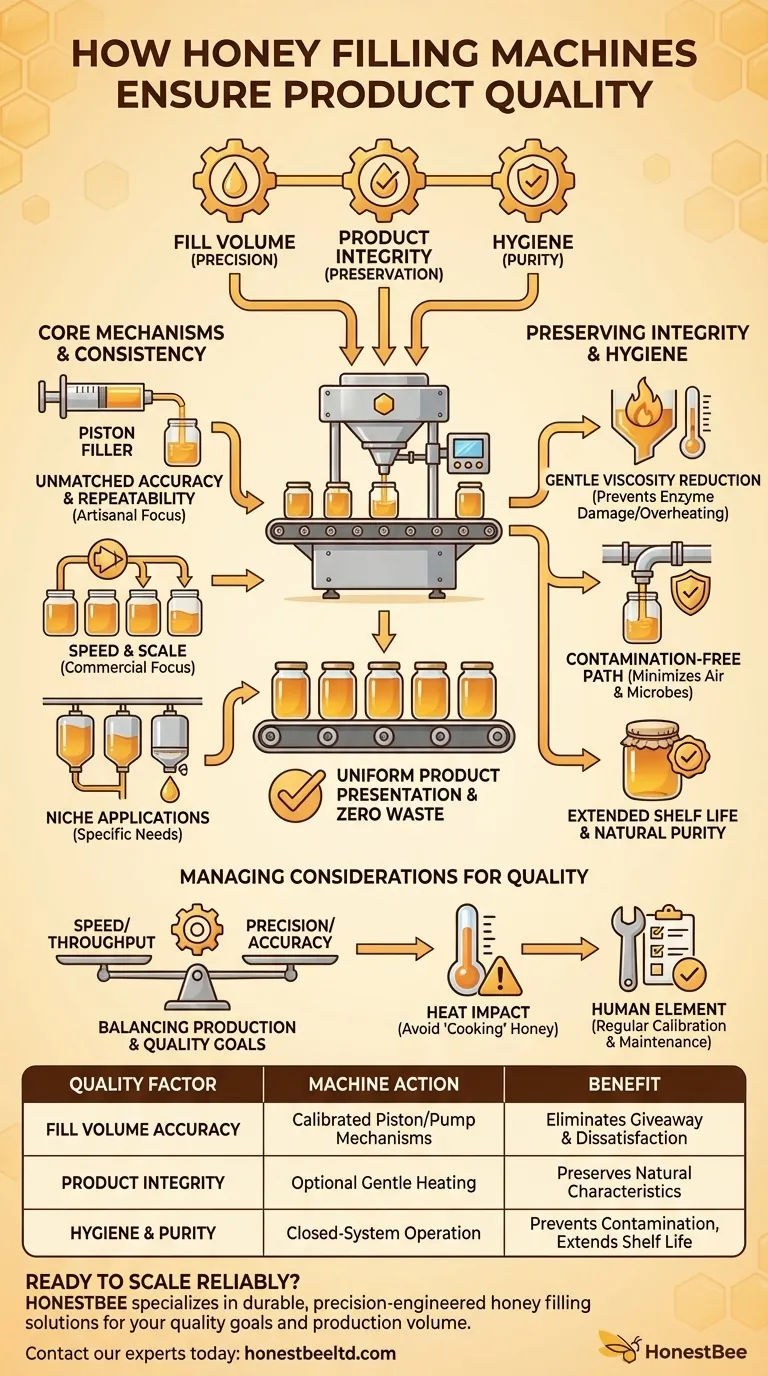

The Foundation of Quality: Precision and Consistency

A machine's primary role in quality assurance is to perform the same task perfectly, thousands of time over. This consistency is fundamental to building consumer trust.

Eliminating Volume Inaccuracy

Manual filling is prone to human error, resulting in underfilled or overfilled jars. Automated fillers, particularly piston fillers, use a calibrated cylinder to dispense an exact, pre-set volume of honey every single time.

This precision eliminates product waste from overfilling and prevents the customer dissatisfaction that comes from underfilling, ensuring every jar meets label specifications.

Ensuring Uniform Product Presentation

Consistent fill levels create a professional and reliable appearance on the retail shelf. When every jar is filled to the same height, it reinforces the perception of a high-quality, trustworthy brand.

Preserving Honey's Natural Integrity

Honey is a delicate product. Its quality can be degraded by improper handling, air exposure, or excessive heat. Filling machines are designed to mitigate these risks.

Controlled Handling to Maintain Viscosity

Honey's high viscosity makes it difficult to pour smoothly. To address this, many filling machines incorporate an optional heating mechanism in the hopper or product path.

This feature gently warms the honey just enough to reduce its viscosity for a smooth, efficient fill. Crucially, this controlled heat prevents overheating, which can destroy the delicate enzymes and subtle flavors that define high-quality honey. This also helps prevent the introduction of air bubbles.

A Closed System for Unmatched Hygiene

From the moment honey enters the machine's hopper to when the container is capped, the process occurs within a controlled or closed system. This automated workflow minimizes the product's exposure to airborne dust, moisture, and microbial contaminants.

By handling the entire process from filling to capping and sealing, the machine ensures a contamination-free path, preserving the honey's natural purity and extending its shelf life.

Understanding the Core Filling Mechanisms

Different machines use different technologies to move honey, each with specific strengths suited for different production scales and honey types.

Piston Fillers: The Standard for Accuracy

Piston fillers are the most common choice for viscous liquids like honey. They operate like a large syringe, drawing a precise volume of honey into a cylinder and then dispensing it into the container. This method offers exceptional volumetric accuracy.

Pump Fillers: Built for Speed and Scale

For high-speed, large-scale operations, pump-based systems are often used. These machines use a pump to regulate a continuous or semi-continuous flow of honey into jars. While extremely fast, they require careful calibration to maintain fill accuracy.

Gravity and Vacuum Fillers: Niche Applications

Gravity fillers rely on the weight of the honey in an overhead tank to fill containers below. This method is simpler but typically better suited for lower-viscosity liquids. Vacuum fillers create a seal on the container and use a vacuum to draw the honey in, a method prized for its consistent fill level relative to the container shape.

Understanding the Trade-offs

While beneficial, automated filling technology is not a magic bullet. Understanding its limitations is key to maximizing quality.

The Cost of High Throughput

There is often a trade-off between speed and absolute precision. A high-speed pump filler may offer incredible throughput but might exhibit slightly more volume variance than a slower, more methodical piston filler. Choosing the right machine means balancing production goals with quality standards.

The Impact of Heat

The heating function is a powerful tool, but it must be used with care. Applying too much heat in an effort to speed up the filling process can "cook" the honey, damaging its flavor profile and nutritional value. A quality machine will have a gentle and well-regulated heating system.

The Human Element: Calibration and Maintenance

A filling machine's performance is entirely dependent on proper setup and maintenance. Regular calibration is essential to ensure fill accuracy over time. Likewise, using the appropriate nozzle design and maintaining a strict cleaning protocol are non-negotiable for preventing contamination and ensuring a smooth operation.

Making the Right Choice for Your Operation

The ideal machine is one that aligns with your specific production goals and commitment to quality.

- If your primary focus is artisanal quality and maximum precision: A piston filler is the superior choice for its unmatched accuracy with viscous honey.

- If your primary focus is high-volume commercial production: A pump-based system offers the necessary speed but requires diligent calibration and quality control to maintain consistency.

- If your primary focus is preserving raw honey properties: Prioritize a machine with a gentle, precise, low-temperature heating system to protect the product's natural integrity.

Ultimately, investing in the right filling technology is a direct investment in your product's quality and your brand's long-term success.

Summary Table:

| Key Quality Factor | How the Machine Ensures It | Benefit |

|---|---|---|

| Fill Volume Accuracy | Uses calibrated piston or pump mechanisms for exact, repeatable fills. | Eliminates product giveaway and customer dissatisfaction. |

| Product Integrity | Optional gentle heating reduces viscosity without damaging enzymes or flavor. | Preserves the honey's natural characteristics and quality. |

| Hygiene & Purity | Closed-system operation from hopper to sealed container. | Prevents contamination, extends shelf life, and ensures purity. |

Ready to protect your honey's quality and scale your production reliably?

HONESTBEE specializes in supplying durable, precision-engineered honey filling machines and beekeeping equipment to commercial apiaries and distributors. Our solutions are designed to deliver the accuracy and hygiene your operation needs to build a trusted brand.

Contact our experts today to find the perfect filling machine for your quality goals and production volume.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What are pump liquid fillers and in what scenarios are they used for honey packaging? Optimize Large-Scale Production

- What is a manual honey filler and where is it used? The Essential Guide for Small-Scale Honey Bottling

- Why is specialized filling and packaging equipment indispensable for the honey export industry? Win Global Markets

- How do I choose a packaging machine? A Systematic Guide to Aligning with Your Production Needs

- What are the common parts of a honey filling machine? Explore Essential Components for Precise Bottling

- How do high-precision honey-filling machines enhance product value? Boost Your Commercial Honey Brand Value

- How do industrial honey filling machines contribute to the efficiency of honey export trade? Boost Global Trade ROI

- How should cost-effectiveness be evaluated when choosing a honey packaging machine? Maximize ROI and Efficiency