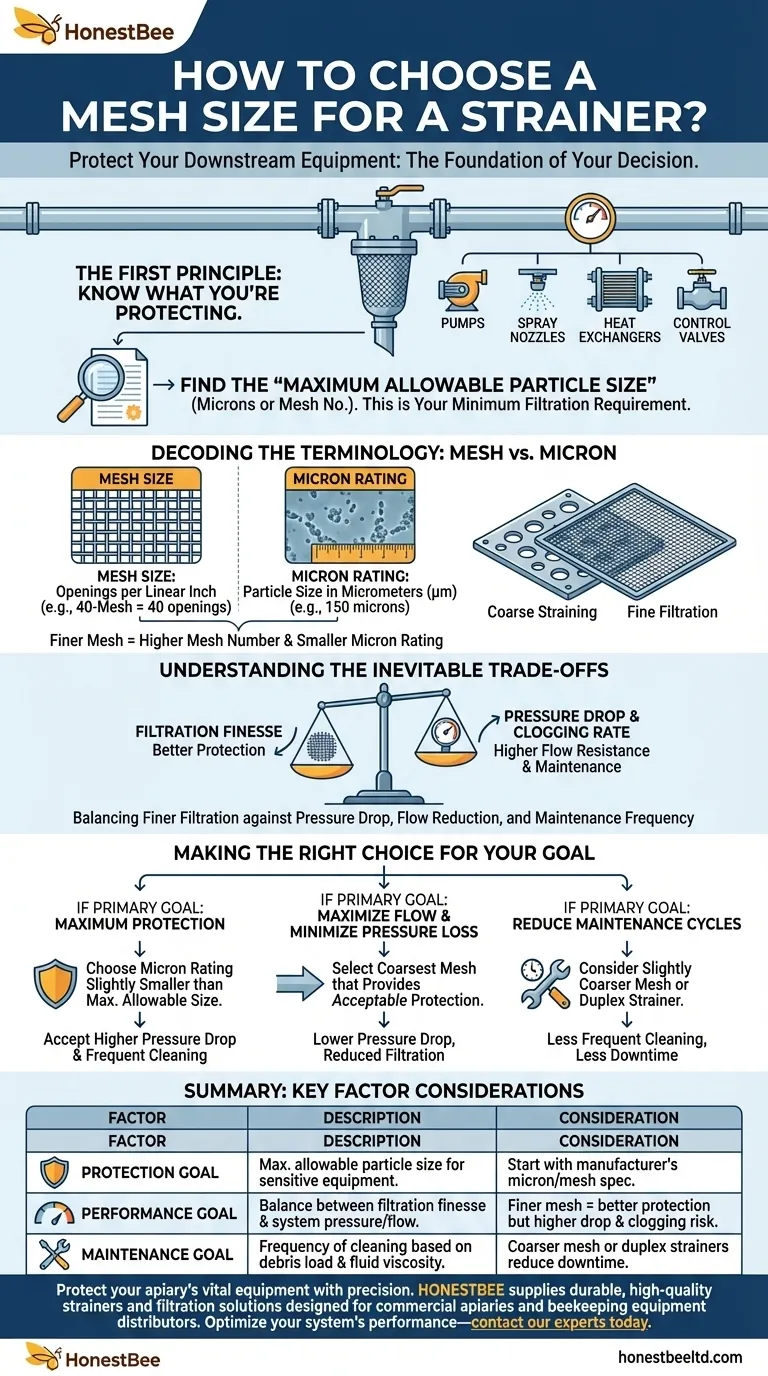

To choose the right mesh size for a strainer, you must identify the maximum particle size that your most sensitive downstream equipment can tolerate. The strainer's mesh must be fine enough to capture any particle larger than this critical dimension. This single factor—protecting your equipment—is the foundation of your entire decision.

The core challenge is not simply filtering out debris, but balancing the need for protection against the operational costs of pressure drop and flow reduction. A finer mesh offers better protection but creates more resistance in your system.

The First Principle: Know What You're Protecting

Before you can select a mesh size, you must have a clear, data-driven answer to one question: What is the most vulnerable component downstream of the strainer?

### Identify the Most Sensitive Component

Your system may have pumps, spray nozzles, heat exchangers, or control valves. Each has a different tolerance for solid particles.

The manufacturer's specification sheet for the most sensitive of these components is your primary source of truth.

### Find the "Maximum Allowable Particle Size"

Look for a specification that defines the largest particle that can safely pass through the component. This is often stated in microns (µm) or as a mesh number.

This value becomes your minimum filtration requirement. The strainer you choose must be able to stop particles of this size or larger.

Decoding the Terminology: Mesh vs. Micron

The terms "mesh" and "micron" are often used interchangeably, but they measure different things. Understanding the distinction is crucial for making an accurate selection.

### What is Mesh Size?

Mesh size refers to the number of openings in a one-inch line of screen. A higher mesh number means more openings per inch, which corresponds to smaller openings and finer filtration.

For example, a 40-mesh screen has 40 openings per inch, while a 200-mesh screen has 200.

### What is a Micron Rating?

A micron (micrometer) is a unit of length equal to one-millionth of a meter. A micron rating is the direct measurement of the size of particle that a filter can capture.

This is a more precise measurement than mesh size. For instance, a 100-mesh screen has openings of about 150 microns.

### Perforated Plate vs. Wire Mesh

For very coarse straining (e.g., removing large debris like rocks or rags), a perforated plate with holes measured in fractions of an inch (e.g., 1/8") is used.

For finer filtration, a wire mesh screen is layered over the perforated plate for support. Your final mesh selection will apply to this wire screen.

Understanding the Inevitable Trade-offs

Choosing a mesh size is an exercise in balancing competing factors. An ideal choice in one area often creates a challenge in another.

### Filtration Finesse vs. Pressure Drop

This is the fundamental trade-off. As you select a finer mesh (higher mesh number) to capture smaller particles, you increase the resistance to flow.

This resistance causes a pressure drop across the strainer. Excessive pressure drop can starve pumps, reduce system efficiency, and decrease overall throughput.

### Clogging Rate and Maintenance Frequency

A finer mesh not only has smaller holes but also less open area for fluid to pass through. It will capture more debris and clog more quickly than a coarser screen.

This directly impacts operations, as a frequently clogging strainer requires more labor for cleaning and creates more downtime.

### Fluid Viscosity and Debris Load

The properties of your process fluid matter significantly. A high-viscosity fluid (like oil) will struggle to pass through a fine mesh, creating an unacceptably high pressure drop.

Likewise, a system with a very high debris load may require a coarser mesh simply to avoid constant and immediate clogging.

Making the Right Choice for Your Goal

Your final decision should be a deliberate compromise based on your system's primary objective. Use the manufacturer's specification for your most sensitive component as your starting point, then adjust based on these operational goals.

- If your primary focus is maximum equipment protection: Choose a mesh size that provides a micron rating slightly smaller than the maximum allowable particle size for your most critical component. Accept the higher potential for pressure drop and more frequent cleaning.

- If your primary focus is maximizing flow and minimizing pressure loss: Select the absolute coarsest mesh that still provides acceptable protection for your downstream equipment. This is common in applications where flow rate is the key performance indicator.

- If your primary focus is reducing maintenance cycles: If your system has a high debris load, consider a slightly coarser mesh than the ideal specification or installing a duplex strainer that allows for cleaning without system shutdown.

Ultimately, selecting the right mesh size is a calculated decision that balances perfect protection with practical operational performance.

Summary Table:

| Key Factor | Description | Consideration |

|---|---|---|

| Protection Goal | Maximum allowable particle size for sensitive downstream equipment. | Start with manufacturer's micron/mesh spec for pumps, nozzles, valves. |

| Performance Goal | Balance between filtration finesse and system pressure drop/flow rate. | Finer mesh = better protection but higher pressure drop and clogging risk. |

| Maintenance Goal | Frequency of cleaning required based on debris load and fluid viscosity. | Coarser mesh or duplex strainers reduce downtime in high-debris systems. |

Protect your apiary's vital equipment with precision. Selecting the right strainer mesh is critical for safeguarding pumps and sprayers in honey processing and hive maintenance systems. HONESTBEE supplies durable, high-quality strainers and filtration solutions designed for the demanding needs of commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations ensure you get the reliable equipment you need to maximize uptime and protect your investment. Optimize your system's performance—contact our experts today for a consultation.

Visual Guide

Related Products

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Honey Filter with Tripod Support Stand

- Professional Stainless Steel Honey Filter with Support Handle

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

People Also Ask

- Why is the use of high-density filter cloth necessary during the processing of stingless bee honey? Ensure Pure Quality

- Why is it important to inspect and replace filters in honey filtering equipment? Protect Your Honey Quality & Equipment

- What are the benefits of drying honey filtering equipment after use? Protect Your Honey Quality & Equipment Investment

- Why is a Synthetic Cloth Mesh used in honey filtration? Ensure Purity and Chemical Integrity in Your Honey Samples

- What size mesh to strain honey? A Guide to the Standard Double-Sieve Method