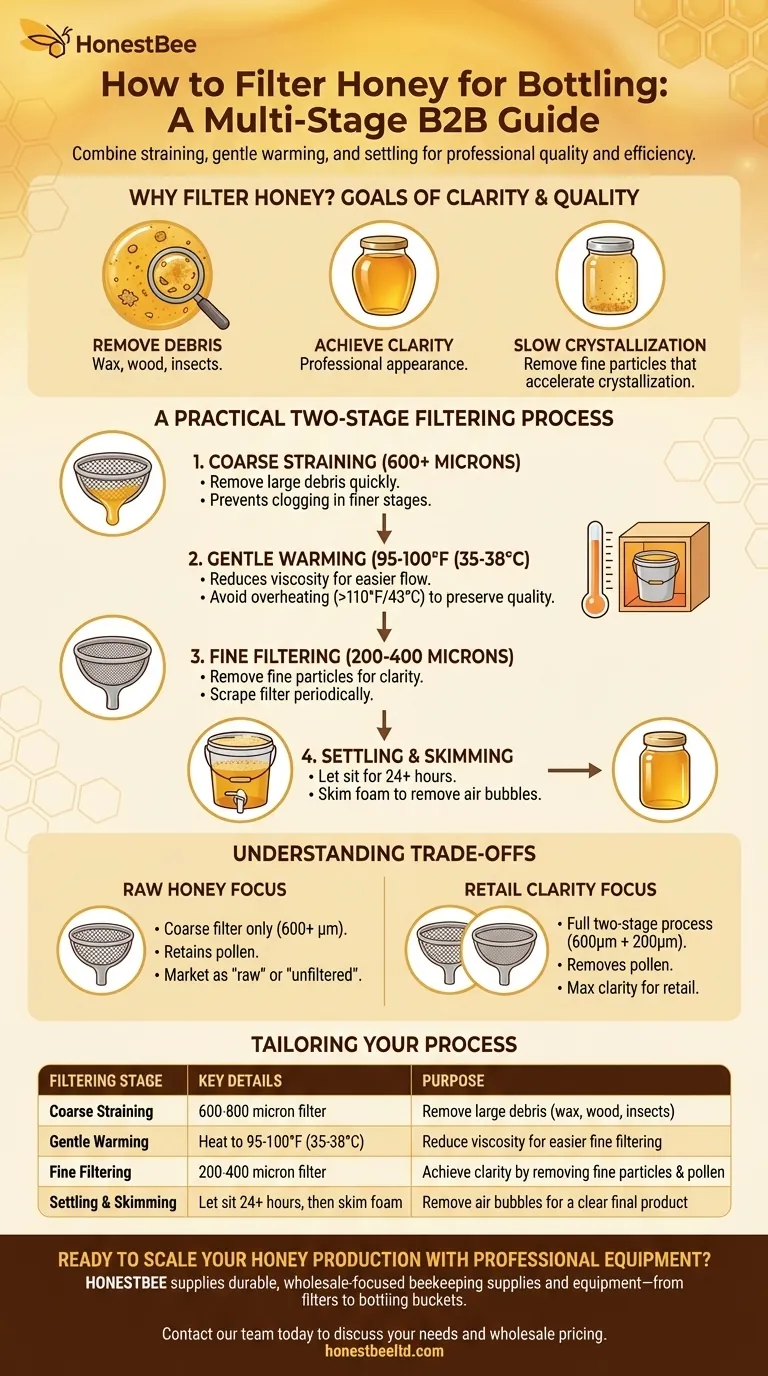

To properly filter honey for bottling, you must use a multi-stage process that combines straining, gentle warming, and settling. This typically involves passing the honey through a coarse filter (around 600 microns) to remove large debris, followed by a finer filter (200-400 microns) to achieve clarity. Allowing the honey to warm slightly and settle afterward is crucial for an efficient process and a professional-quality final product.

The key to effective honey filtering is not just the mesh of the strainer, but a deliberate process. Success depends on controlling honey's viscosity with gentle heat and allowing time for gravity to separate impurities and air.

Why Filter Honey? The Goal of Clarity and Quality

Before detailing the process, it's essential to understand the objectives. Filtering is not just about cleaning; it's about preparing the honey for a specific final product.

Removing Physical Debris

The most basic goal is to remove debris from the extraction process. This includes bits of wax cappings, wood from the frames, and any unfortunate bees or insects.

Achieving a Clear, Professional Appearance

For many consumers, clear, golden honey is the standard. Fine filtering removes smaller suspended particles, like pollen grains and "hive trash," which can make the honey appear cloudy.

Slowing Crystallization

Fine particles, including pollen and dust, can act as nucleation sites that initiate and accelerate crystallization. Removing these particles can help keep the honey in its liquid state for longer on the shelf.

A Practical Two-Stage Filtering Process

A methodical approach yields the best results without damaging the honey's delicate qualities. This process is standard for many small-scale and craft beekeepers.

Step 1: Coarse Straining (600+ Microns)

Immediately after extraction, the honey should be poured through a coarse filter. A 600-micron or 800-micron filter is ideal for this first pass.

This initial step is designed to catch all the large debris quickly without clogging. It prepares the honey for the next, finer stage.

Step 2: The Importance of Gentle Warming

Honey is viscous, meaning it flows slowly. When gently warmed, its viscosity drops dramatically, allowing it to pass through finer filters with ease.

The ideal temperature is 95-100°F (35-38°C). You can achieve this by placing your honey bucket in a warm room, a "hot box" with a low-wattage lightbulb, or even a vehicle on a sunny day.

Step 3: Fine Filtering (200-400 Microns)

Once warmed, the honey is ready for its final filtering. A 200-micron or 400-micron filter will remove the vast majority of remaining fine particles.

Because these filters are so fine, they can clog. Work patiently and scrape the collected material from the filter surface periodically to maintain flow.

Step 4: Settling and Skimming

After the final filtering, pour the honey into a clean bottling bucket equipped with a honey gate (a type of spigot). Let it sit undisturbed for at least 24 hours.

This settling period allows microscopic air bubbles, which were introduced during extraction and filtering, to rise to the surface. This forms a thin layer of foam that can be skimmed off just before bottling, ensuring perfectly clear honey in the jar.

Understanding the Trade-offs

Filtering is a balance between purity and preservation. Your choice of process depends entirely on your end goal.

Filter Mesh vs. "Raw" Honey

Many consumers seek out "raw" honey, believing it contains beneficial pollen and enzymes. Aggressive filtering can remove this pollen.

If you intend to market your honey as raw, it is standard practice to use only a coarse filter (600 microns or larger) to remove only the largest non-honey debris.

The Critical Impact of Heat

While warming honey is essential for efficient filtering, overheating is destructive. Temperatures above 110°F (43°C) can begin to degrade the beneficial enzymes and delicate flavor compounds that make your honey unique.

Never heat honey quickly or directly. Gentle, low, and slow warming is the only acceptable method.

Final Preparation and Hygiene

The final step before bottling is ensuring your equipment is pristine. Bottles must be perfectly clean and dry.

Any moisture inside the bottle can increase the honey's overall water content, creating a risk of fermentation and spoilage over time.

Making the Right Choice for Your Goal

Your filtering strategy should align directly with the product you wish to create.

- If your primary focus is crystal-clear honey for retail: Use the full two-stage process (600 micron, then 200 micron) with gentle warming and a 24-hour settling period.

- If your primary focus is marketing "raw" or "unfiltered" honey: Use only a single, coarse straining (600+ micron) to remove large debris while retaining all pollen.

- If your primary focus is honey for personal use: A single pass through a medium filter (around 400 microns) after warming is often the perfect balance of clarity and simplicity.

By mastering this process, you gain complete control over the quality, appearance, and character of your final product.

Summary Table:

| Filtering Stage | Key Details | Purpose |

|---|---|---|

| Coarse Straining | 600-800 micron filter | Remove large debris (wax, wood, insects) |

| Gentle Warming | Heat to 95-100°F (35-38°C) | Reduce viscosity for easier fine filtering |

| Fine Filtering | 200-400 micron filter | Achieve clarity by removing fine particles and pollen |

| Settling & Skimming | Let sit 24+ hours, then skim foam | Remove air bubbles for a clear final product |

Ready to Scale Your Honey Production with Professional Equipment?

As a commercial beekeeper or distributor, you need reliable, efficient tools to maintain the highest quality standards. HONESTBEE supplies durable, wholesale-focused beekeeping supplies and equipment—from coarse and fine filters to bottling buckets with honey gates—designed for high-volume operations.

Let us help you streamline your filtering and bottling process for a superior product. Contact our team today to discuss your equipment needs and wholesale pricing.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

- Professional Stainless Steel Honey Filter with Support Handle

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

People Also Ask

- What are the technical advantages of using a vacuum filtration system? Speed and Clarity for Separating Extracts

- What role does industrial honey filtration play? Enhance Market Value with Professional Processing Equipment

- Why is a high vacuum filtration system necessary for propolis ethanol extracts? Ensure Purity & Industrial Efficiency

- What issues does a honey filtration system address? Ensure Purity & Safety Before Final Packaging

- How does a honey filtering machine contribute to product quality? Elevate Your Honey to Premium Market Standards

- How can a honey filtering machine be utilized for filtering raw honey? Maximize Purity and Commercial Value

- What function does honey filtration and clarification equipment serve? Enhance Purity and Value in Your Production

- What role does large-scale honey concentration and filtration equipment play? Elevate Your Regional Brand Standards