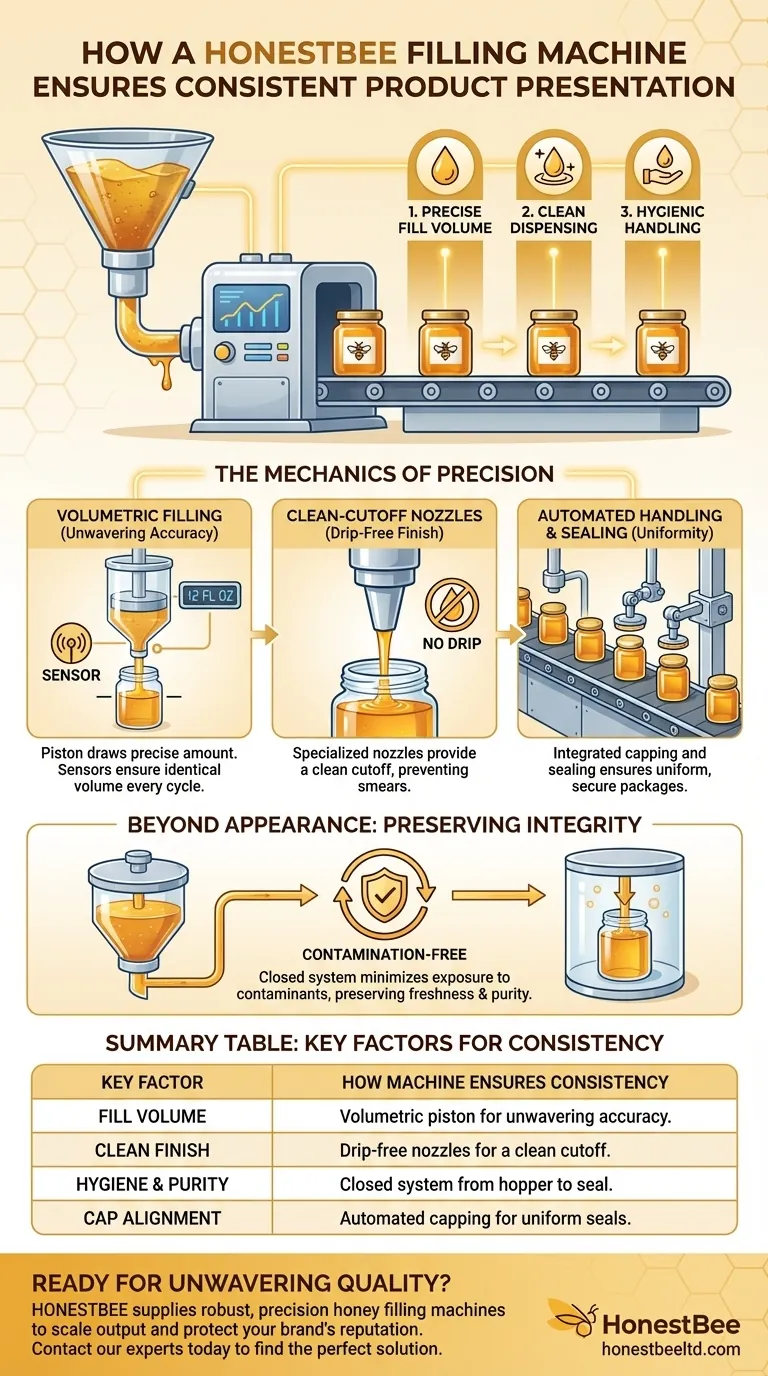

A honey filling machine ensures consistent product presentation by automating the three factors that define a professional-looking product: precise fill volume, clean dispensing, and hygienic handling. This technology removes the variability inherent in manual processes, guaranteeing that every jar, bottle, or container meets the same high standard of quality and appearance.

The core function of a honey filling machine is not just to dispense honey, but to codify your brand's promise of quality into a physical, repeatable form. It transforms the final product from a variable craft into a consistent, professional offering that builds consumer trust.

The Mechanics of Precision

To understand how these machines achieve such consistency, we must look at the specific mechanisms that control the process. Each element is designed to eliminate a potential source of human error or inconsistency.

Volumetric Filling for Unwavering Accuracy

At the heart of most honey fillers is a volumetric piston or a similar dispensing system. An operator inputs the exact volume to be dispensed, such as 12 fluid ounces.

For every cycle, the machine draws that precise amount of honey from a hopper and dispenses it into the container. Sensors and actuators govern this process, ensuring the volume is identical time after time, which eliminates the unprofessional look of underfilled or overfilled jars.

Clean-Cutoff Nozzles for a Drip-Free Finish

Product presentation is instantly ruined by drips and smears on the container's threads or label. Honey filling machines use specialized drip-free nozzles.

These nozzles provide a clean cutoff the moment the fill is complete, preventing residual honey from stringing or dripping. This ensures a clean package that is ready for immediate capping without manual wiping.

Automated Handling and Sealing

Consistency extends beyond the fill level. Fully automated lines integrate filling with capping and sealing.

This ensures every cap is applied with the same torque and every seal is perfectly aligned. The result is a secure, tamper-evident package that looks uniform and professional on the retail shelf.

Beyond Appearance: Preserving Product Integrity

True product presentation is also about the quality of the product inside the package. Automated filling plays a critical role in maintaining the honey's purity.

A Contamination-Free Workflow

Honey filling machines create a closed system, moving the product from a sealed hopper directly into the final container. This minimizes the honey's exposure to airborne dust, microbes, and other contaminants.

By automating the process from filling to sealing, the machine preserves the freshness and natural purity of the honey, which is a core component of a premium brand's presentation.

Understanding the Trade-offs

While the benefits are clear, adopting this technology requires a realistic understanding of its operational demands and limitations.

The Initial Investment

Automated and semi-automated equipment represents a significant capital expenditure compared to manual filling. The return on investment comes from increased speed, reduced product waste, and enhanced brand value over time.

Managing Honey's Viscosity

Honey's thickness changes dramatically with temperature. An unheated, highly viscous honey can strain the machine and lead to inaccurate fills. Most professional operations require integrated heating elements in the hopper to maintain a consistent temperature and viscosity for reliable filling.

Rigorous Cleaning and Maintenance

To ensure the hygienic benefits, these machines demand strict cleaning protocols. They must be disassembled and sanitized regularly to prevent cross-contamination and bacterial growth, adding to the operational overhead.

Making the Right Choice for Your Operation

The decision to invest in a honey filling machine should be aligned with your specific business goals.

- If your primary focus is moving beyond manual filling: A semi-automatic tabletop piston filler provides a major leap in consistency and speed without the cost of a fully automated line.

- If your primary focus is scaling for wholesale or retail: An integrated filling and capping line is essential to produce a consistent, shelf-ready product at a high volume.

- If your primary focus is premium or raw honey: Prioritize a machine built entirely from food-grade stainless steel with components that are easy to disassemble for thorough, verifiable cleaning.

Ultimately, investing in the right filling technology is an investment in your brand's promise of quality, from the first jar to the millionth.

Summary Table:

| Key Factor | How the Machine Ensures Consistency |

|---|---|

| Fill Volume | Uses a volumetric piston system for unwavering accuracy, eliminating under/overfilling. |

| Clean Finish | Employs drip-free nozzles for a clean cutoff, preventing smears on container threads. |

| Hygiene & Purity | Creates a closed system from hopper to seal, minimizing contamination risk. |

| Cap Alignment | Integrated automated capping ensures uniform, tamper-evident seals on every jar. |

Ready to build a brand known for its unwavering quality? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the robust, precision honey filling machines needed to produce a consistently professional product. Our wholesale-focused operations ensure you get the right equipment to scale your output and protect your brand's reputation. Contact our experts today to find the perfect filling solution for your operation.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What technical advantages do automated honey filling and packaging machines provide? Elevate Your Retail Compliance

- What role do honey filling machines play in enhancing the value of organic honey? Protect Purity and Scale Your Brand

- How do automated honey-filling machines enhance product quality? Advanced Precision for Commercial Apiaries

- Why is high-precision honey-filling equipment essential? Ensure Consistency for Fir and Chestnut Honey

- What kinds of products and containers can volumetric liquid machines fill? Versatile Filling Solutions Explained

- Why is food-grade stainless steel recommended for honey filling machines? Ensure Purity & Compliance

- How do industrial honey filling machines assist honey producers? Unlock Retail Success & Higher Margins

- How do industrial-grade honey filling machines enhance commercial value? Scale Your Brand with Precision Technology