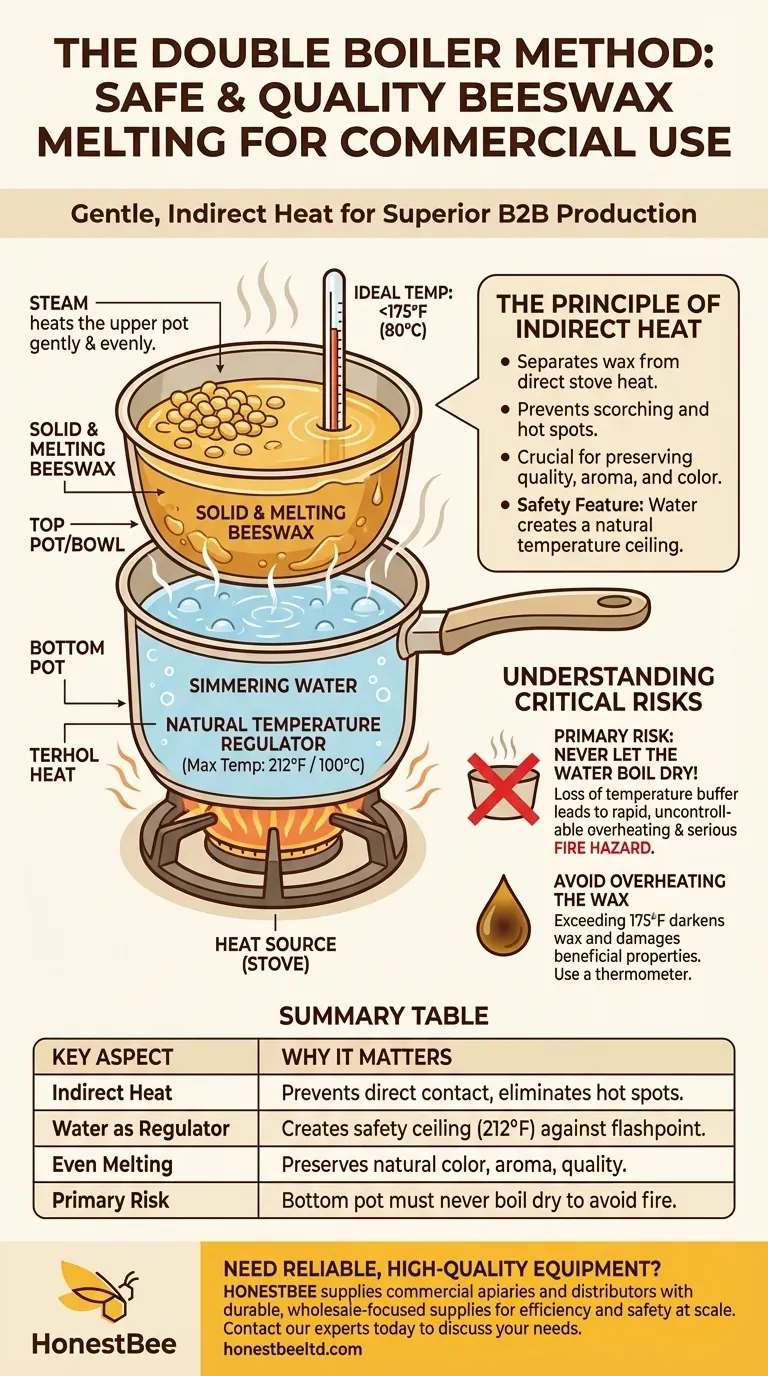

The double boiler method works by using steam as a gentle, indirect heat source. It consists of two stacked pots: the bottom pot holds simmering water, and the top pot holds the beeswax. The steam from the water heats the upper pot, melting the wax evenly and preventing it from scorching or reaching its dangerous flashpoint.

The core problem with melting beeswax is that it is both flammable and easily damaged by direct heat. The double boiler solves this by using water as a natural temperature regulator, ensuring the wax melts safely and gently without degrading its quality.

The Principle of Indirect Heat

The effectiveness of the double boiler method lies in its ability to separate the beeswax from the direct heat source of the stove. This simple separation is the key to both safety and quality control.

How It Works: The Two-Chamber System

A double boiler is essentially a two-chamber system. The lower chamber holds water, which is heated by the stove. The upper chamber, which can be a metal bowl or a smaller saucepan, rests above the water and holds the beeswax.

The heat is transferred from the stove to the water, which then turns to steam. This steam gently and uniformly heats the bottom and sides of the upper chamber, causing the wax to melt without creating intense hot spots.

Why Water is the Key Safety Feature

Water is the most critical element in this process. Because water boils at 212°F (100°C), it creates a natural temperature ceiling for the system.

As long as there is water in the bottom pot, the temperature of the steam heating the wax will not significantly exceed this limit. This prevents the beeswax from overheating to its flashpoint, which is the temperature at which its vapors can ignite.

Achieving an Even, Gentle Melt

Direct heat on a pan can create hot spots that scorch and discolor the wax, altering its natural properties and aroma.

The double boiler's indirect heat ensures a slow, even melt. This is crucial for preserving the delicate quality of the beeswax, especially for use in cosmetics, balms, or high-quality candles. The beeswax melting point is around 144°F (62°C), and this method keeps the temperature well within a safe working range.

Understanding the Critical Risks

While the double boiler is a safe method, it is not without risks if operated improperly. Understanding these potential pitfalls is essential for avoiding accidents and ensuring a good outcome.

The Primary Risk: Never Let the Water Boil Dry

The most significant danger is allowing the water in the bottom pot to boil away completely.

If the bottom pot runs dry, you have lost your temperature buffer. The direct heat from the stove will now make contact with the pot holding the wax, causing the temperature to rise rapidly and uncontrollably. This can quickly scorch the wax and create a serious fire hazard.

Avoid Overheating the Wax

Even with water in the pot, you should still manage your heat source. The ideal temperature for melted beeswax is just above its melting point, generally not exceeding 175°F (80°C).

Pushing the temperature higher can cause the wax to darken and can damage its beneficial properties. Use a thermometer to monitor the temperature and keep your stove on a medium-low setting.

Making the Right Choice for Your Goal

Your approach should be guided by what you intend to do with the melted beeswax.

- If your primary focus is safety and basic melting: Always ensure the bottom pan has plenty of water and never leave the stove unattended.

- If your primary focus is preserving the wax's natural color and aroma: Use a thermometer to keep the temperature below 175°F (80°C) at all times.

- If your primary focus is efficiency: Use smaller beeswax pellets or grated chunks, as they will melt much faster and more evenly than a large, solid block.

Ultimately, the double boiler method provides the control needed to handle beeswax safely and effectively for any project.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Indirect Heat | Prevents direct contact with the stove, eliminating hot spots and scorching. |

| Water as a Regulator | Creates a natural temperature ceiling (212°F / 100°C) for safe melting. |

| Even Melting | Preserves the wax's natural color, aroma, and beneficial properties. |

| Primary Risk | The bottom pot must never boil dry to avoid a fire hazard. |

Need reliable, high-quality equipment for your beekeeping operation? Melting wax safely is just one part of a successful harvest. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused supplies needed for efficiency and safety at scale. Contact our experts today to discuss your equipment needs and ensure the quality of your products from hive to harvest.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What equipment is commonly used for heating and processing honey? Essential Tools for Every Beekeeper

- What is the effect of heating on honey? Preserve Quality with Controlled Warming

- What is melter honey used for? A Low-Cost Ingredient for Bakers and Brewers

- How to permanently decrystallize honey? Embrace Its Natural State for Maximum Quality

- What are the negative effects of overheating honey? Preserve Your Honey's Natural Quality