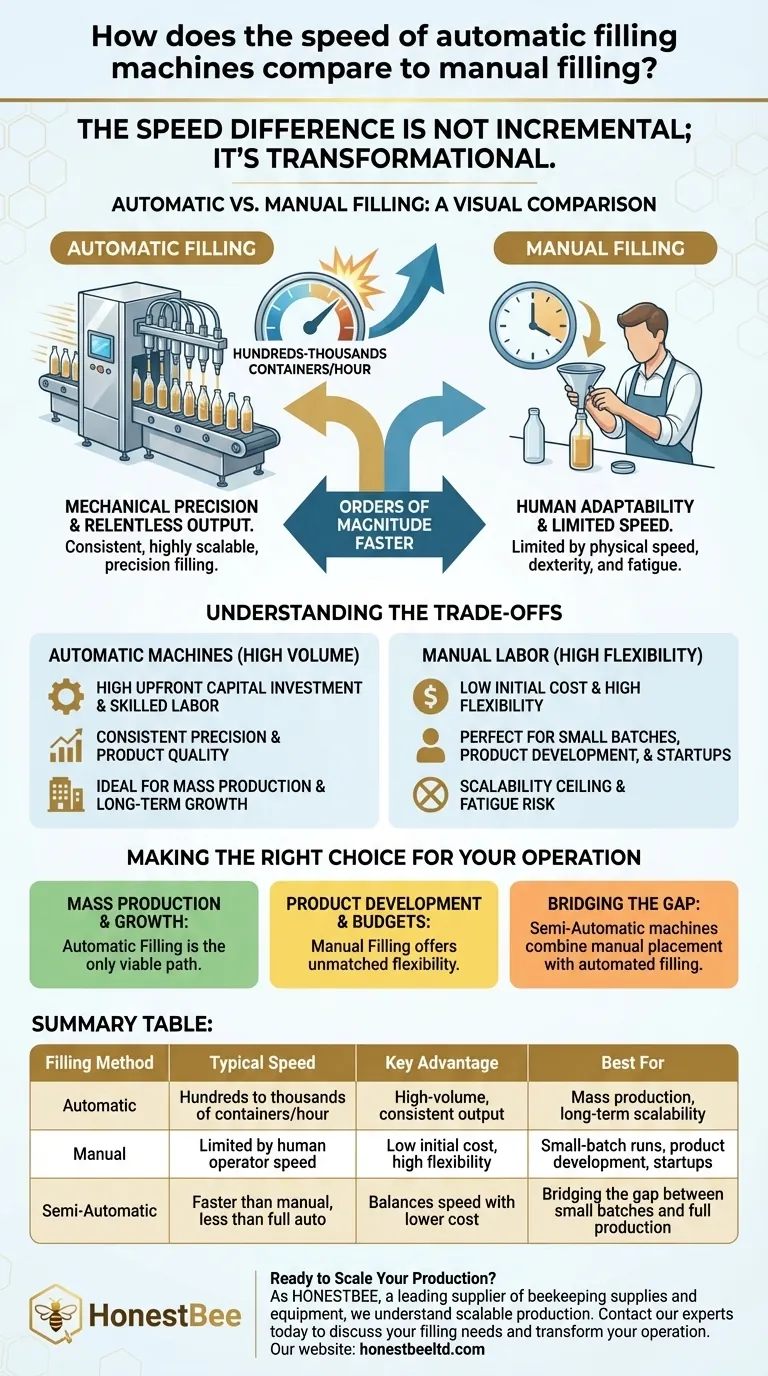

The speed difference is not incremental; it's transformational. Automatic filling machines are orders of magnitude faster than manual filling, capable of processing hundreds or even thousands of containers per hour. In contrast, manual filling is fundamentally limited by the physical speed, dexterity, and endurance of human labor.

While speed is the most obvious difference, the real decision between automatic and manual filling hinges on a deeper question: Are you optimizing for high-volume scalability or for small-scale flexibility and lower initial cost?

The Fundamental Difference in Throughput

The core distinction lies in how each method handles volume and repetition. One leverages mechanical precision for relentless output, while the other relies on human adaptability.

Defining Automatic Speed

An automatic filling machine is designed for one primary purpose: high-speed, repeatable dispensing. Its performance is measured in containers per minute (CPM) or per hour (CPH).

This mechanical nature means its speed is consistent and highly scalable. As production demands increase, the machine can run longer or faster (within its design limits) to meet the new target.

The Limitations of Manual Filling

Manual filling speed is dictated entirely by the individual operator. While a skilled worker can be efficient, they are subject to fatigue, which leads to slower speeds and increased fill inaccuracies over a shift.

Scaling up a manual operation is a linear process—to double your output, you must double your labor force, which also doubles labor costs and management complexity.

Consistency as a Byproduct of Speed

A critical benefit tied directly to the speed of automation is precision. An automatic filler will dispense the exact same volume every single time, which is crucial for product quality and cost control.

Manual filling, even with careful operators, will always have a higher degree of variability from one container to the next.

Understanding the Trade-offs

Choosing a system based on speed alone is a common mistake. The faster option is not always the better one for a specific business case.

The Cost of Automation

The primary drawback of automatic machinery is the significant upfront capital investment. These systems are complex and represent a major financial commitment.

They also require skilled operators for setup, changeovers, and maintenance, adding to the operational cost.

The Flexibility of Manual Labor

Manual filling excels in high-mix, low-volume environments. It is far more flexible and cost-effective when you are frequently changing products, formulas, or container sizes.

The initial cost is minimal, making it the ideal entry point for startups, pilot runs, or artisanal production.

The Scalability Ceiling

Manual filling has a practical scalability ceiling. At a certain point, the floor space, labor management, and quality control challenges of a large manual team become more costly and complex than investing in an automated solution.

Making the Right Choice for Your Operation

To select the right method, you must align the system's strengths with your primary business objective.

- If your primary focus is mass production and long-term growth: An automatic filling machine is the only viable path to achieve the necessary speed and scalability.

- If your primary focus is product development, small-batch runs, or budget constraints: Manual filling provides unmatched flexibility and the lowest possible barrier to entry.

- If your primary focus is bridging the gap between small batches and full-scale production: Consider semi-automatic machines that combine manual placement with automated filling to increase speed and consistency without the full cost of automation.

Ultimately, choosing the right filling method is about understanding where your business is today and where you plan for it to be tomorrow.

Summary Table:

| Filling Method | Typical Speed | Key Advantage | Best For |

|---|---|---|---|

| Automatic | Hundreds to thousands of containers/hour | High-volume, consistent output | Mass production, long-term scalability |

| Manual | Limited by human operator speed | Low initial cost, high flexibility | Small-batch runs, product development, startups |

| Semi-Automatic | Faster than manual, less than full auto | Balances speed with lower cost | Bridging the gap between small batches and full production |

Ready to Scale Your Production with the Right Filling Solution?

As HONESTBEE, a leading supplier of beekeeping supplies and equipment to commercial apiaries and distributors, we understand that efficient, scalable production is critical to your success. Whether you're moving from manual processes to your first automatic filler or upgrading your existing line for higher throughput, we provide the robust, reliable equipment you need.

Our wholesale-focused operations ensure you get commercial-grade filling solutions designed for durability and high-volume output, helping you maximize efficiency and meet growing demand.

Contact our experts today to discuss your specific needs and find the perfect filling machine to transform your operation's speed and scalability.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- What role do industrial honey-filling machines play in processing specialty honeys? Scale Your Brand for Export

- What challenges can arise from packaging honey without a suitable filling machine? Optimize Your Production Today

- What are the different types of honey stick machines based on automation? Choose the Right Model for Your Apiary's Scale

- What is the core value of automated honey filling machines? Scale Your Production and Ensure Global Quality Standards

- What is the recommended quarterly maintenance for a honey stick machine? Ensure Long-Term Reliability and Efficiency

- Why are industrial-grade honey-filling machines essential? Boost Your Commercial Scale and Export Efficiency

- How does a piston filling machine work for honey packaging? Achieve Precise, Drip-Free Filling

- How do automatic honey filling machines contribute to beekeeping sustainability? Boost Your Apiary's ROI