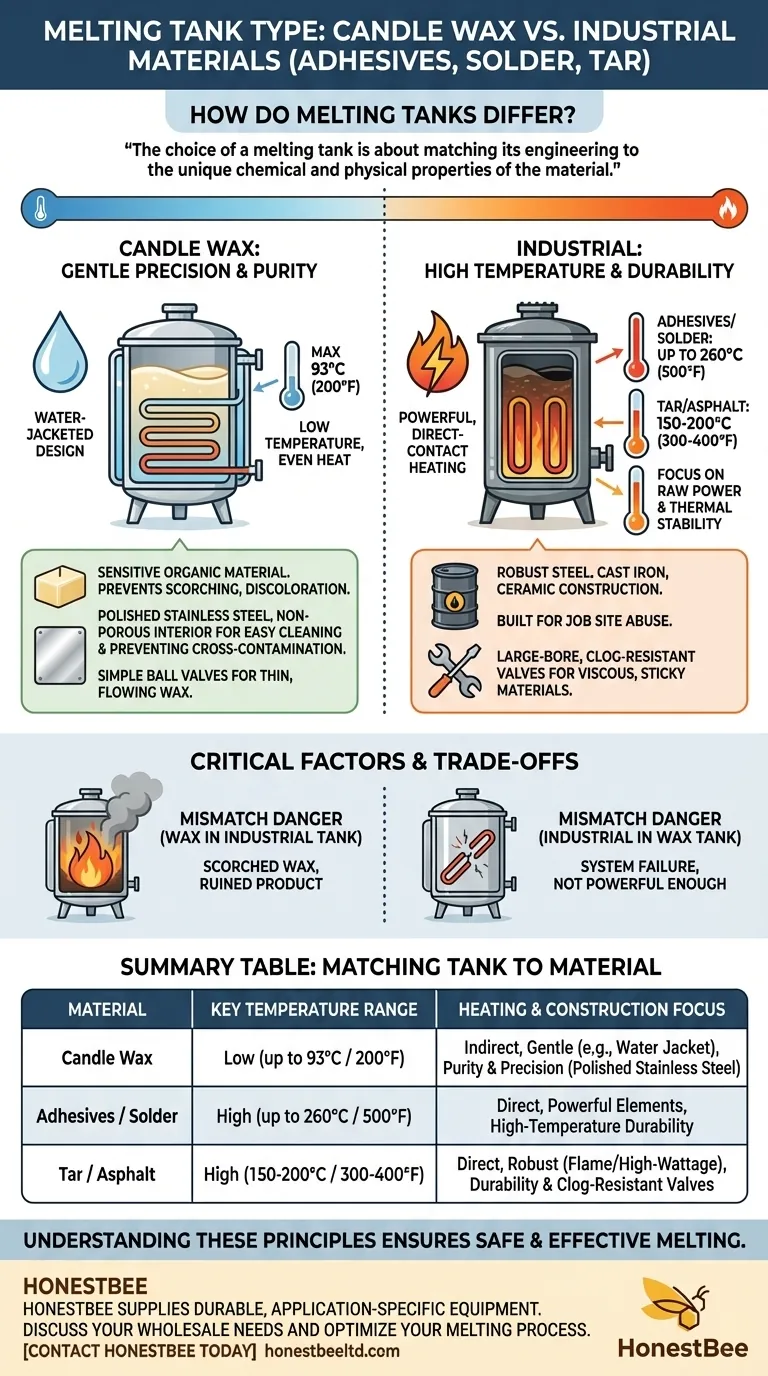

The fundamental differences between a melting tank for candle wax and one for industrial materials like adhesives, solder, or tar are driven by three factors: required temperature, the precision of heat control, and the need to prevent product contamination. Candle wax is a delicate organic material requiring low, even heat, whereas industrial compounds demand high temperatures and durability over finesse.

The choice of a melting tank is not about the tank itself, but about matching its engineering to the unique chemical and physical properties of the material. Mismatching the tool to the substance risks destroying the product, damaging the equipment, or creating a significant safety hazard.

The Critical Factor: Operating Temperature

The single greatest differentiator between these tanks is the temperature range they are built to handle. This dictates the heating method, power requirements, and materials used in construction.

The Low-Temperature Precision of Candle Wax

Candle wax, especially organic soy wax, is extremely sensitive to heat. It can be ruined at temperatures over 60°C (140°F) and must never be heated above 93°C (200°F) to prevent scorching, discoloration, and damage to its scent-holding properties.

This requires tanks with gentle, indirect heating methods, such as a water-jacketed design, which provides exceptionally even heat distribution and prevents hot spots that would burn the wax.

The High-Temperature Demands of Adhesives and Solder

Industrial adhesives and solder operate at the other end of the spectrum. Many hot-melt adhesives require temperatures up to 260°C (500°F) to achieve the correct viscosity and bonding characteristics.

These tanks utilize powerful, direct-contact heating elements designed for rapid heating and sustaining high temperatures. The focus is on raw power and thermal stability, not the gentle precision needed for wax.

The Robust Heating for Tar

Tar and asphalt must be heated to a high temperature, often in the 150-200°C (300-400°F) range, to become liquid enough for application. Because of its high viscosity, the tank must provide sustained, powerful heat to the entire volume.

The engineering priority for a tar kettle is durability and power, often using direct-flame or high-wattage electric elements in a heavy-duty steel vessel. Precision is secondary to the need to simply liquefy a thick, dense material.

Material Purity and Tank Construction

Beyond temperature, the tank's internal surface and material composition are dictated by the end product's requirements for purity.

Why Candle Wax Demands a Polished Finish

For candle making, preventing cross-contamination between different colors or scents is critical. A small amount of a previous batch's dark red wax or cinnamon scent can ruin a new batch of white, lavender-scented wax.

Therefore, candle wax melters are almost always made of stainless steel with a highly polished, non-porous interior. This makes the tank easy to clean thoroughly between batches, ensuring product purity.

Function Over Finesse for Industrial Materials

For materials like tar, solder, or many industrial adhesives, absolute purity is not the primary concern. The focus is on durability and heat resistance.

Tar kettles are made of thick, rugged steel, built to withstand job site abuse. Solder pots are often made of cast iron or ceramic, chosen for their ability to handle extreme temperatures without degrading. Cleaning is for maintenance, not to prevent subtle contamination.

Understanding the Trade-offs

Using the wrong type of tank is not just inefficient; it is often dangerous and destructive.

The Danger of Mismatching Equipment

You cannot use a high-temperature tar heater for candle wax. The aggressive, direct heating would scorch the wax almost instantly, rendering it useless.

Conversely, a candle wax melter would be destroyed by any attempt to melt solder in it. Its heating elements are not powerful enough to reach the required temperature, and the system is not designed for such thermal stress.

Viscosity and Dispensing Challenges

The design of the dispensing valve is also a critical difference. Candle wax is thin and flows easily when melted, allowing for simple ball valves.

Tar is incredibly thick and sticky, requiring large-bore, clog-resistant valves specifically designed to handle viscous materials without seizing up. An adhesive tank will have a valve system matched to that specific adhesive's flow properties at temperature.

Matching the Tank to Your Material

Choosing the right equipment comes down to a clear understanding of your material's properties and your final goal.

- If your primary focus is product quality and purity (like candle making): Prioritize tanks with indirect heating (like a water jacket), precise digital temperature controls, and a polished stainless steel interior.

- If your primary focus is high-temperature industrial bonding (like adhesives or solder): You need a tank with powerful, direct heating elements and materials capable of sustaining temperatures well over 200°C (400°F).

- If your primary focus is bulk melting of viscous materials (like tar or asphalt): Look for robust, heavy-duty steel construction with powerful heating and large, clog-resistant valves designed for thick substances.

Understanding these core engineering principles ensures you select a tool that is not only effective but also safe and protective of your valuable materials.

Summary Table:

| Material | Key Temperature Range | Primary Heating Method | Tank Construction Focus |

|---|---|---|---|

| Candle Wax | Low (up to 93°C / 200°F) | Indirect, Gentle (e.g., Water Jacket) | Purity & Precision (Polished Stainless Steel) |

| Adhesives / Solder | High (up to 260°C / 500°F) | Direct, Powerful Elements | High-Temperature Durability |

| Tar / Asphalt | High (150-200°C / 300-400°F) | Direct, Robust (Flame/High-Wattage) | Durability & Clog-Resistant Valves |

Equip Your Operation with the Right Melting Tank

Selecting the correct melting equipment is critical for product quality, efficiency, and safety. Whether you are a commercial candlemaker requiring precise temperature control or an industrial distributor handling high-temperature adhesives, the right tank makes all the difference.

HONESTBEE supplies durable, application-specific beekeeping and related equipment to commercial apiaries and distributors. We understand the importance of robust, reliable tools for demanding operations.

Contact HONESTBEE today to discuss your wholesale equipment needs and ensure your melting process is optimized for success.

Visual Guide

Related Products

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Stainless Steel Uncapping Tank with Stand and Strainer

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Professional Honey Storage Tank with Agitation System

People Also Ask

- What are the benefits of precise temperature control in honey heating tanks? Preserve Quality and Efficiency

- How does a honey heating tank preserve the quality of honey? Gentle Heat for Purity & Flavor

- What is the primary function of a honey heating tank? Master Your Honey Processing with Precision Control

- What is the primary role of a honey heating tank? Enhance Your Honey Processing Flow and Quality

- Why is industrial-grade constant temperature heating equipment essential for the detoxification processing of specialty honey? Ensure Consumer Safety