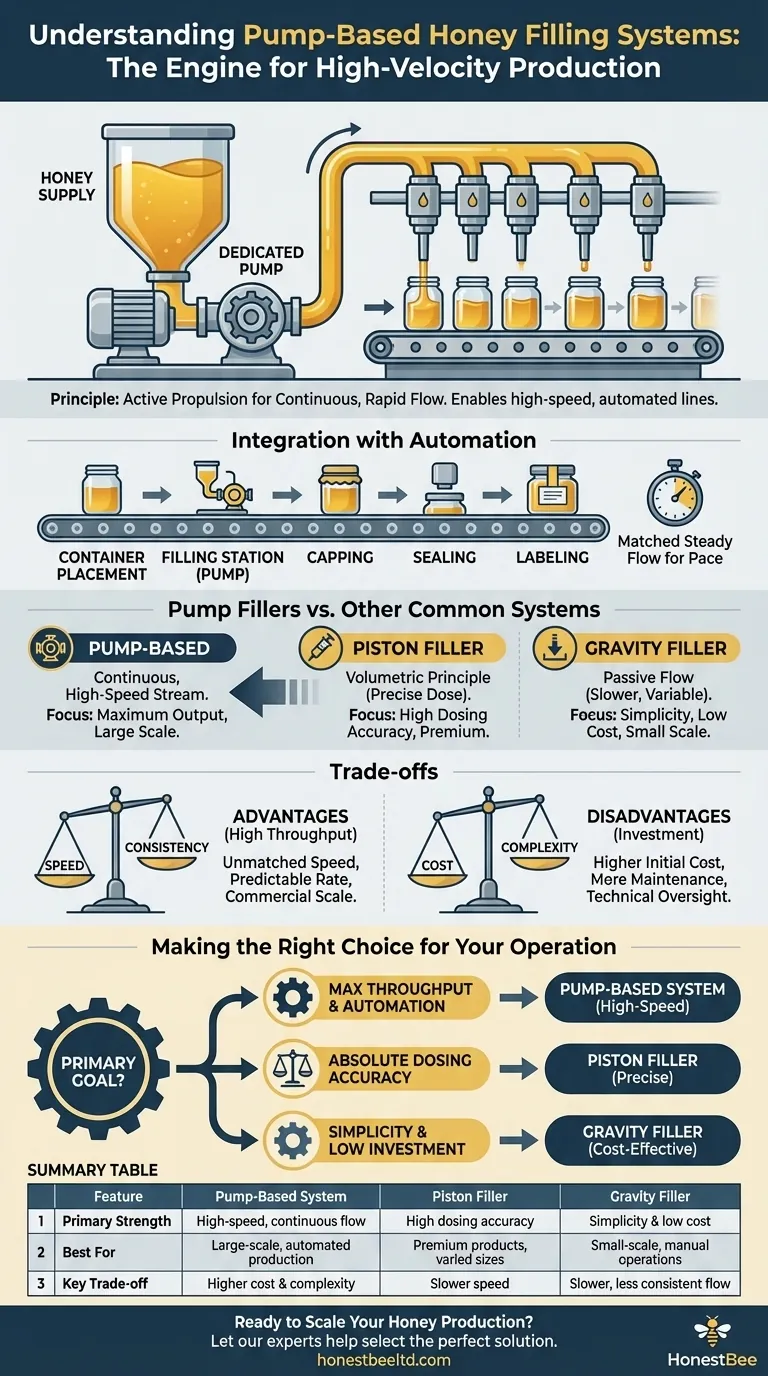

At its core, a pump-based system in a honey filling machine is an engine for high-velocity production. It uses a dedicated pump to actively move honey from a holding tank to the filling nozzle, enabling a rapid and continuous flow. This method is the standard for fully automated, high-volume operations where speed and consistent throughput are the primary objectives.

While other filling systems often operate batch-by-batch, a pump-based system creates a constant, high-speed stream of product. This makes it the definitive choice for large-scale production lines where maximizing output is the most critical measure of success.

How Pump-Based Systems Function

A pump-based filler is a key component in a larger, integrated packaging line. Its design prioritizes speed and automation above all else.

The Principle of Continuous Flow

Unlike a gravity-fed system that relies on the weight of the honey, a pump-based machine actively propels the product. The honey is stored in a large hopper and the pump ensures it is fed to the filling heads at a constant rate and pressure.

This active-propulsion method is crucial for maintaining speed, especially when dealing with the high viscosity of honey.

Integration with Automation

Pump-based systems are rarely standalone units. They are designed to integrate seamlessly into a fully automated line.

This includes automated container placement, conveyors that move jars to the filling station, and subsequent stages for capping, sealing, and labeling. The pump's steady flow matches the pace of the entire automated process.

Pump Fillers vs. Other Common Systems

The decision to use a pump system becomes clear when you compare it to the other primary methods used for honey filling. Each is engineered for a different operational priority.

Pump vs. Piston Fillers

Piston fillers operate on a volumetric principle. A piston retracts to draw a precise, pre-set amount of honey into a cylinder and then pushes it out into the container.

This method offers extremely high dosing accuracy. It is ideal for operations that require precise fill weights for a wide range of container sizes or for packaging premium products where every gram counts. Pumps prioritize speed; pistons prioritize per-unit precision.

Pump vs. Gravity Fillers

Gravity fillers are the simplest design. They use the force of gravity to allow honey to flow from an overhead tank into the containers below.

While reliable and cost-effective, they are significantly slower than pump systems. Their flow rate can also decrease as the level in the hopper drops, potentially impacting consistency. Gravity fillers are best suited for startups or small-scale operations with lower output demands.

Understanding the Trade-offs

No system is superior in all contexts. Choosing a pump-based filler involves a clear trade-off between speed and cost.

Primary Advantage: Unmatched Speed

The main reason to invest in a pump system is for maximum throughput. The continuous flow allows for more containers to be filled per minute than any other method, making it essential for commercial-scale production.

Primary Advantage: Consistent Throughput

Because the pump provides a constant, regulated flow, the production rate is highly predictable. This consistency is vital for planning and meeting the demands of large supply chains.

Key Disadvantage: Higher Initial Cost

The primary drawback is a significantly higher initial investment. The pump, its motor, and the associated control systems make this a more expensive option compared to simpler gravity or piston fillers.

Key Disadvantage: Increased Mechanical Complexity

A pump system has more moving parts than a gravity filler. This introduces more potential points for maintenance and failure, requiring a higher level of technical oversight to ensure long-term reliability.

Making the Right Choice for Your Operation

To select the correct system, you must first define your single most important production goal.

- If your primary focus is maximum throughput and full automation: A pump-based system is engineered specifically for the high-speed, continuous demands of large-scale production.

- If your primary focus is absolute dosing accuracy for varied products: A piston filler provides superior volumetric precision and is more flexible for packaging high-value honey or filling diverse container sizes.

- If your primary focus is simplicity and low initial investment: A gravity-fed system is the most cost-effective and reliable solution for small-scale, manual, or semi-automated operations.

Choosing the right filling technology is a matter of aligning the machine's core strength with your operation's most critical objective.

Summary Table:

| Feature | Pump-Based System | Piston Filler | Gravity Filler |

|---|---|---|---|

| Primary Strength | High-speed, continuous flow | High dosing accuracy | Simplicity & low cost |

| Best For | Large-scale, automated production | Premium products, varied container sizes | Small-scale, manual operations |

| Key Trade-off | Higher cost & complexity | Slower speed | Slower, less consistent flow |

Ready to Scale Your Honey Production?

At HONESTBEE, we specialize in equipping commercial apiaries and beekeeping equipment distributors with the right machinery for their operational goals. Our range of high-performance honey filling machines, including advanced pump-based systems, is designed to maximize your throughput and efficiency.

Let our experts help you select the perfect filling solution to meet your production targets. Contact us today for a personalized consultation and discover how we can support your wholesale-focused growth.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- What role do automated honey filling machines play? Elevate Efficiency & Standardization in Honey Processing

- What are the application advantages of honey filling machines? Elevate Precision and Hygiene in Your Production Chain

- What functions do professional honey filtration and filling equipment serve in the post-processing of honey? Pro Results

- What is an automatic filling valve? The Essential Component for Hydronic System Health

- What is a VFFS liquid packaging machine and how is it used for honey? Optimize Your High-Speed Sachet Production

- What is the best way to bottle honey? Preserve Quality and Maximize Your Harvest

- What is the working principle of a honey stick machine? Master High-Precision VFFS Packaging Technology

- What technical advantages do automated honey-filling machines offer? Enhance Purity and Precision in Every Bottle