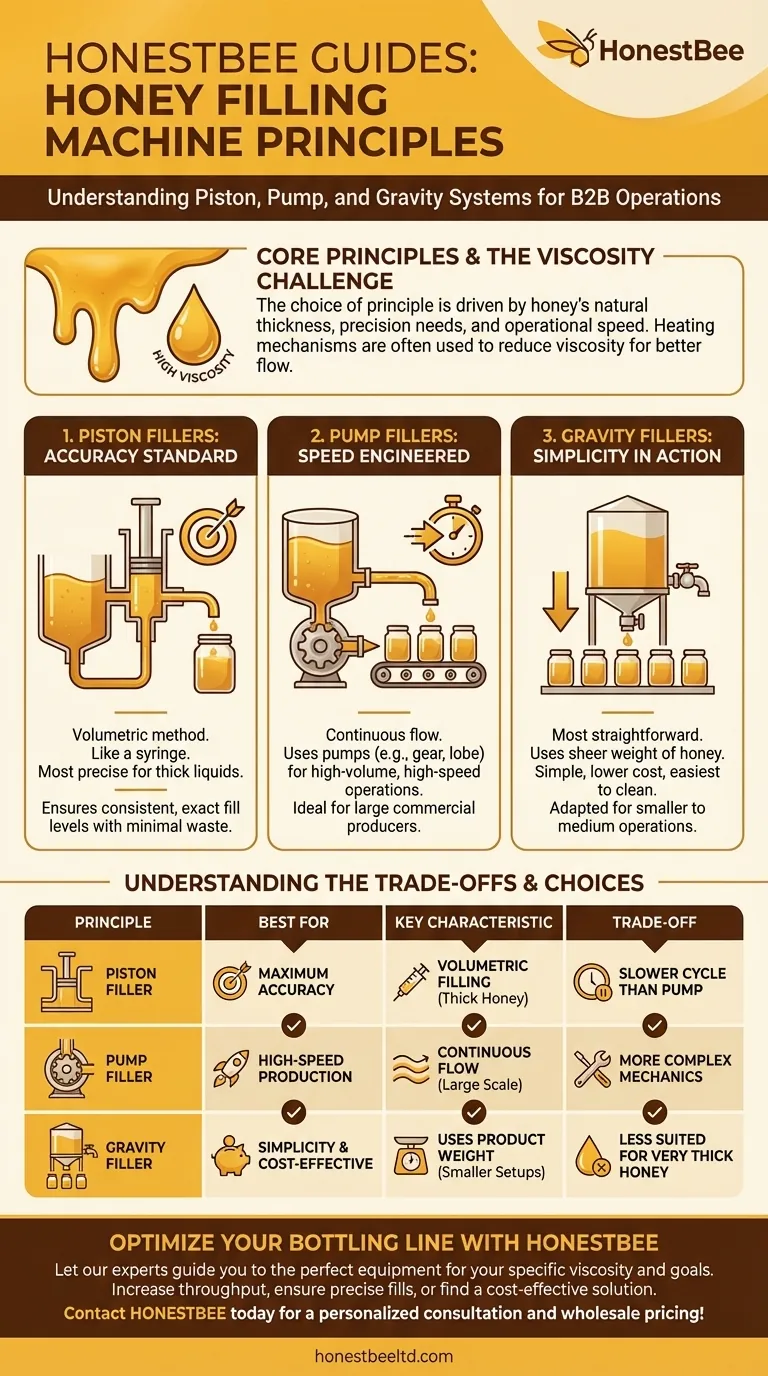

At their core, honey filling machines operate on one of three main principles. These are piston filling, pump-based filling, and gravity filling. The choice of which principle to use is driven by the honey's viscosity, the need for precision, and the desired operational speed.

The fundamental challenge in bottling honey is managing its high viscosity. Piston fillers offer the most precise solution for thick honey, while pump and gravity systems provide alternatives optimized for speed and simplicity, respectively.

The Core Filling Principles Explained

To select the right equipment, you must first understand the mechanics behind each filling method and how it interacts with a product like honey.

Piston Fillers: The Standard for Accuracy

A piston filler works much like a large syringe. A piston retracts within a cylinder, drawing in a precise, pre-set volume of honey.

The piston then pushes forward, dispensing that exact amount into the container. This volumetric method is extremely accurate and is the preferred choice for thick, viscous liquids, ensuring minimal waste and consistent fill levels.

Pump Fillers: Engineered for Speed

Pump-based systems are designed for high-volume, high-speed operations. These machines use various types of pumps (such as gear pumps or lobe pumps) to regulate and propel a continuous flow of honey into the jars.

The fill volume is typically controlled by the timing of the pump's operation or a flow meter. This method is ideal for large commercial producers where throughput is a critical metric.

Gravity Fillers: Simplicity in Action

A gravity filler is the most straightforward of the principles. It operates by holding the honey in a tank positioned above the filling nozzles.

When a valve opens, the sheer weight of the honey causes it to flow down and fill the containers below. While best suited for thinner liquids, this method can be adapted for honey, particularly in small to medium-sized operations where simplicity and lower cost are priorities.

Why Honey's Viscosity is the Deciding Factor

Honey's natural thickness presents the primary obstacle in any bottling process. The machine's design must directly address this characteristic to function effectively.

The Challenge of Thick Honey

High viscosity makes honey flow slowly and unevenly, which can lead to inaccurate fills and the introduction of air bubbles. A machine that cannot handle this thickness will be inefficient and produce an inconsistent final product.

The Role of Heating Mechanisms

To counteract high viscosity, many honey filling machines incorporate heating systems. These gently warm the honey in the holding tank or on its way to the nozzle.

This warming process reduces the honey's viscosity, allowing it to flow more smoothly and quickly. The result is a faster, more accurate fill with fewer air bubbles, all without compromising the honey's natural integrity.

Understanding the Trade-offs

No single principle is universally superior. The optimal choice depends on balancing the competing demands of accuracy, speed, and operational complexity.

Accuracy vs. Speed

Piston fillers offer unmatched volumetric accuracy, which is critical for high-value products. However, their cycle-based operation (draw, then dispense) can be slower than the continuous flow of a pump-based system designed for maximum throughput.

Complexity vs. Simplicity

Gravity fillers are mechanically simple, making them easier to operate, clean, and maintain. In contrast, automated piston and pump systems are more complex but provide the speed, efficiency, and consistency required for commercial-scale production.

Product Handling

All professional-grade machines are designed to handle honey gently. The goal is to move the product efficiently without damaging its delicate structure or introducing unwanted air. The choice of principle is less about quality and more about matching the mechanics to your production volume.

Making the Right Choice for Your Goal

Your specific production needs will determine which filling principle is the most logical investment for your operation.

- If your primary focus is maximum accuracy and consistent volume: A piston filler is the ideal choice, as its volumetric action is perfectly suited for viscous honey.

- If your primary focus is high-speed, commercial-scale production: A pump-based system will deliver the throughput necessary to meet high demand.

- If your primary focus is a cost-effective solution for a smaller operation: A gravity filler offers a simple and reliable method, especially if your honey is less viscous or warmed before filling.

Ultimately, understanding these core principles empowers you to select the technology that best aligns with your product and your business goals.

Summary Table:

| Principle | Best For | Key Characteristic |

|---|---|---|

| Piston Filler | Maximum Accuracy | Volumetric filling for thick, viscous honey |

| Pump Filler | High-Speed Production | Continuous flow for large-scale operations |

| Gravity Filler | Simplicity & Cost-Effectiveness | Uses product weight, ideal for smaller setups |

Ready to Optimize Your Honey Bottling Line?

Choosing the right filling principle is critical for the efficiency and profitability of your commercial apiary or distribution business. At HONESTBEE, we specialize in supplying high-performance beekeeping equipment, including honey filling machines tailored for wholesale operations.

We can help you:

- Increase throughput with high-speed pump fillers for large-scale production.

- Ensure precise fills and minimize waste with accurate piston fillers for high-value honey.

- Find a cost-effective solution with reliable gravity systems for smaller batches.

Let our experts guide you to the perfect equipment for your specific honey viscosity and production goals. Contact HONESTBEE today for a personalized consultation and wholesale pricing!

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- How does the filling station work in a honey stick machine? Achieve Perfect Fill Accuracy

- What impact do honey processing and filling machines have on apiaries affected by Varroa? Offset Costs with Efficiency

- What are the different types of honey fillers? A Guide to Manual, Semi & Fully-Automatic Fillers

- How do automated honey-filling and hive-making machines support Varroa mite control in commercial apiaries?

- How does the use of standardized honey-filling machines improve distribution efficiency? 5 Key Benefits for Scale

- What are the primary advantages of high-precision honey-filling machines? Boost Efficiency & Quality in Commercial Labs

- What are the working principles of a honey filling machine? Master Precision and Viscosity Control

- How do high-precision honey filling machines manage diverse SKU requirements? Optimize Production with Flexible Tooling