At its core, a top-bar hive is defined by its simple, trough-like design. The key features are a series of removable bars from which bees build their own comb, a long horizontal body that eliminates the need for stacking heavy boxes, and sloped sides that guide natural comb construction. This design stands in contrast to the modular, multi-box Langstroth hive common in commercial beekeeping.

A top-bar hive is fundamentally a system for the beekeeper, not just a box for the bees. Its design prioritizes ease of access, minimal heavy lifting, and a less intrusive management style, making it a popular choice for hobbyists and natural beekeeping advocates.

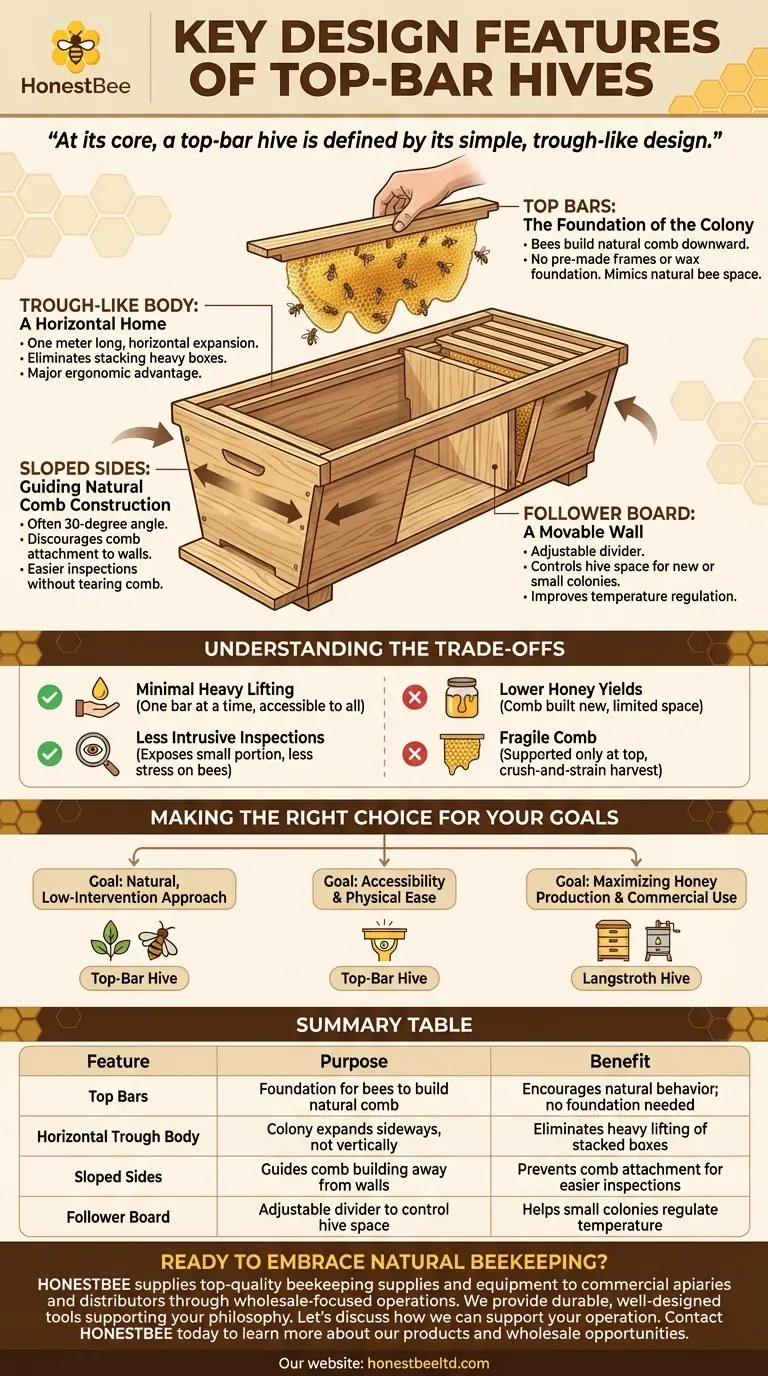

The Anatomy of a Top-Bar Hive

Understanding the purpose behind each design feature reveals the philosophy of top-bar beekeeping: working with the bees' natural tendencies in a way that is manageable for the beekeeper.

The Top Bars: The Foundation of the Colony

The single most defining feature is the set of "top bars" that rest across the top of the hive body. Bees hang from these bars and build their comb downward, just as they would in a natural cavity.

These bars are specifically sized, typically between 1 1/4 and 1 3/8 inches wide. This dimension is critical as it mimics the natural spacing bees leave between their combs, a concept known as bee space.

Unlike in a standard Langstroth hive, top-bar hives do not use pre-made frames or wax foundation. This allows bees to build their own comb at the size and scale they see fit, a key principle of "natural" beekeeping.

The Trough-like Body: A Horizontal Home

The hive body is a single, long trough, often about one meter in length. The colony expands horizontally along the bars rather than vertically through stacked boxes.

This horizontal orientation is a major ergonomic advantage. The beekeeper never has to lift heavy boxes (or "supers") that can weigh 50 pounds or more. Inspections and harvests only require lifting one bar at a time.

Sloped Sides: Guiding Natural Comb Construction

Many top-bar hive designs feature sides that slope inwards, often at a 30-degree angle. This is not merely an aesthetic choice.

The slope discourages the bees from attaching their newly built comb to the walls of the hive. This makes it far easier for the beekeeper to lift a bar out for inspection without tearing the comb and angering the colony.

The Follower Board: A Movable Wall

A critical component is the "follower board," a solid divider shaped to fit the hive's internal profile. It acts as a movable wall within the hive.

This allows the beekeeper to adjust the size of the space the bees occupy. A smaller space is easier for a new or small colony to warm and defend, improving its chances of survival and growth.

Understanding the Trade-offs

The simplicity of the top-bar hive presents a clear set of advantages and disadvantages compared to the industry-standard Langstroth hive.

Advantage: Minimal Heavy Lifting

The "one bar at a time" management style makes this hive ideal for individuals who cannot or do not want to lift heavy objects. It makes the hobby accessible to a much wider range of people.

Advantage: Less Intrusive Inspections

When inspecting a top-bar hive, you only expose a small portion of the colony at a time. This is less stressful for the bees compared to removing the entire roof and inner cover of a Langstroth hive.

Disadvantage: Lower Honey Yields

Because the comb must be built new by the bees each time, and space is more limited, top-bar hives generally produce less surplus honey than a Langstroth hive.

Disadvantage: Fragile Comb

The comb is supported only by the top bar, making it more fragile than the four-sided support of a Langstroth frame. This means honey cannot be extracted using a centrifuge; it must be harvested by crushing and straining the comb, which destroys it.

Making the Right Choice for Your Goals

Your beekeeping goals should directly inform your choice of hive style. The design of the top-bar hive makes it exceptionally well-suited for some objectives but less so for others.

- If your primary focus is a natural, low-intervention approach: The top-bar hive's design aligns perfectly by allowing bees to build their own comb with minimal heavy lifting required from you.

- If your primary focus is accessibility and physical ease of management: The top-bar hive is an excellent choice, as its horizontal design completely eliminates the need to lift heavy honey boxes.

- If your primary focus is maximizing honey production or commercial use: The modular Langstroth hive's compatibility with standard honey extraction equipment makes it the far more efficient choice.

Understanding these core design principles empowers you to select the hive that best aligns with your personal beekeeping philosophy.

Summary Table:

| Feature | Purpose | Benefit |

|---|---|---|

| Top Bars | Foundation for bees to build natural comb | Encourages natural bee behavior; no foundation needed |

| Horizontal Trough Body | Colony expands sideways, not vertically | Eliminates heavy lifting of stacked boxes |

| Sloped Sides | Guides comb building away from walls | Prevents comb attachment for easier, less intrusive inspections |

| Follower Board | Adjustable divider to control hive space | Helps small colonies regulate temperature and defend the hive |

Ready to Embrace Natural Beekeeping?

Whether you're a hobbyist starting your first colony or a distributor looking for reliable equipment, the right hive design is crucial for success. HONESTBEE supplies top-quality beekeeping supplies and equipment to commercial apiaries and distributors through our wholesale-focused operations.

We provide the durable, well-designed tools that support your beekeeping philosophy, from top-bar hives for natural management to the full range of essential gear.

Let's discuss how we can support your operation. Contact HONESTBEE today to learn more about our products and wholesale opportunities.

Visual Guide

Related Products

- Top Bar Beehive for Beekeeping Wholesales Kenya Top Bar Hive

- Long Langstroth Style Horizontal Top Bar Hive for Wholesale

- HONESTBEE Professional Multi-Functional Hive Tool with Ergonomic Wood Handle

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

People Also Ask

- Are top bar hives better? A Guide to Natural Beekeeping and Ergonomic Design

- Which is better Kenya top bar hive or Langstroth? Choose the Right Hive for Your Goals

- Why are hive inspections easier with Top Bar Hives? Achieve a Calmer, Safer Approach to Beekeeping

- How is honey harvested from a top-bar hive? A Guide to Simple, Low-Equipment Processing

- What is the quickest method to harvest honey from a top bar hive? A Guide to the Simple 'Cut and Crush' Method