At its core, a honey bottle labeling machine drives significant gains in production efficiency, reduces operational costs, minimizes costly human errors, and dramatically improves the final appearance and marketability of your product. It automates the slow, inconsistent process of manual labeling, transforming it into a fast, precise, and repeatable operation.

The decision to use a honey bottle labeling machine is about more than just speed. It represents a strategic shift from a labor-intensive process to a scalable system that ensures brand consistency and professional quality on every single unit.

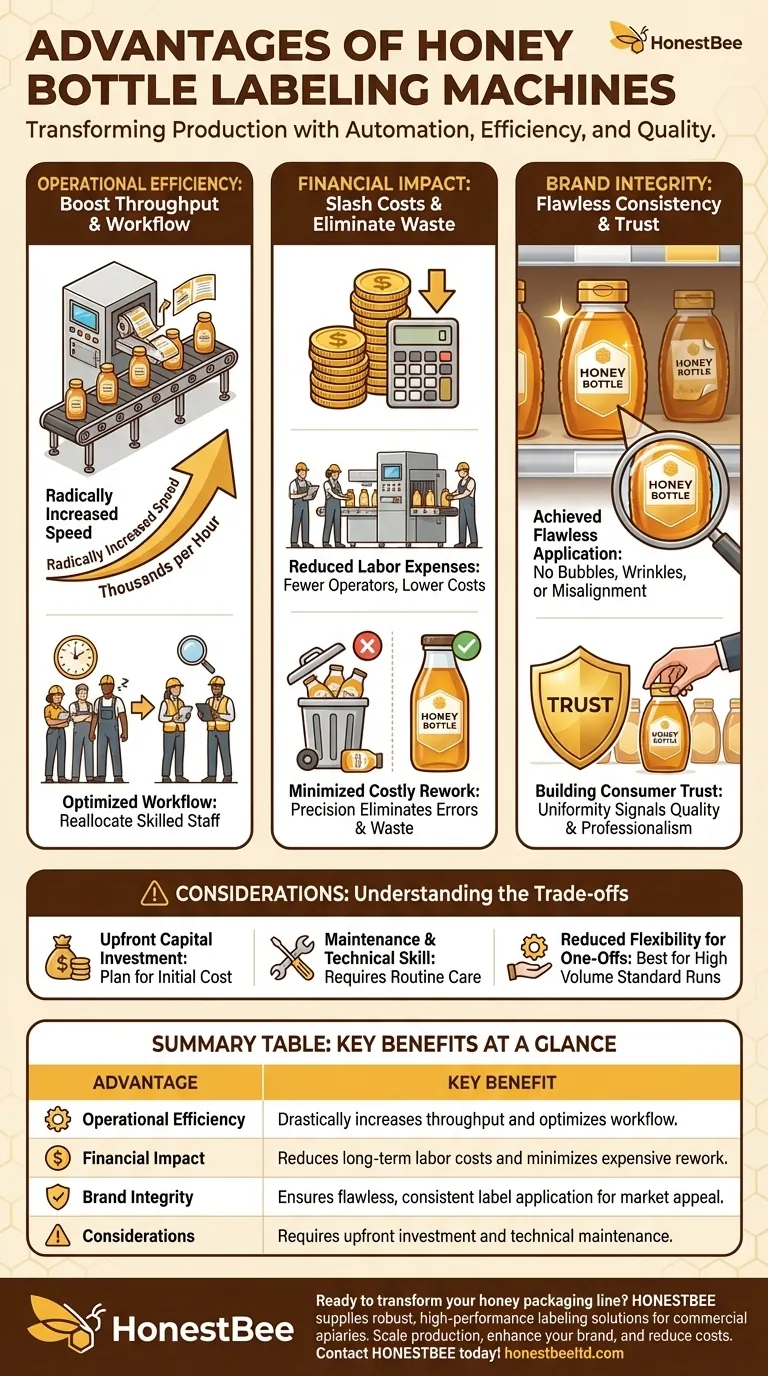

The Core Advantage: Operational Efficiency

Investing in an automated labeler fundamentally changes your production capacity. It removes one of the most common bottlenecks in a packaging line.

Radically Increasing Throughput

An automatic labeling machine operates continuously at speeds far exceeding manual or even semi-automatic methods. Where a person might label a few bottles per minute, a machine can process thousands per hour.

This dramatic increase in speed means you can meet larger orders, respond to market demand faster, and reduce the overall time from production to shelf.

Optimizing Your Workflow

By automating the repetitive task of labeling, you free up your skilled team members. They can be reallocated to more complex, value-added tasks like quality control, inventory management, or new product preparation, making your entire operation more productive.

Financial Impact: Reducing Long-Term Costs

While there is an initial investment, a labeling machine delivers a clear financial return by addressing two major sources of expense: labor and errors.

Slashing Labor Expenses

A single labeling machine requires only a few operators to manage a high-volume output. This drastically reduces the need for a large workforce dedicated to labeling.

You save not only on wages but also on the associated costs of recruitment, training, and ongoing supervision for a large manual labeling team.

Minimizing Costly Rework

Manual labeling is prone to mistakes—crooked labels, incorrect placement, or even applying the wrong label entirely. Each mistake costs time and money in wasted materials and rework.

A machine uses precise positioning and consistent application, ensuring every bottle is labeled correctly the first time, virtually eliminating these preventable losses.

Brand Integrity: The Power of Consistency

On a crowded shelf, presentation is critical. A labeling machine ensures your product looks professional and trustworthy every time.

Achieving Flawless Application

Using advanced sensors and precise mechanical settings, these machines control the exact placement and tension of each label. This results in a tight, clean fit with no bubbles or wrinkles.

This level of precision is impossible to replicate consistently by hand, and it directly contributes to a high-quality aesthetic that catches the consumer's eye.

Building Consumer Trust

A uniform, professionally labeled product line signals quality and attention to detail. This consistency builds brand recognition and consumer trust, making your product stand out against competitors with less polished packaging.

Understanding the Trade-offs

No technology is a perfect solution. Objectivity requires acknowledging the potential downsides of investing in an automatic labeler.

The Upfront Capital Investment

The primary barrier is the initial purchase price. A high-quality labeling machine is a significant capital expense that must be planned for and justified by your production volume and growth goals.

Maintenance and Technical Skill

These are mechanical systems that require routine maintenance, cleaning, and occasional troubleshooting. You will need staff with the technical aptitude to operate the machine and perform basic maintenance to prevent downtime.

Reduced Flexibility for One-Offs

While excellent for high-volume runs of a standard product, a machine can be less efficient for very small, custom, or one-off batches that require significant changeover time between different bottle sizes or label types.

Making the Right Choice for Your Goal

To determine if this investment is right for you, consider your primary business objective.

- If your primary focus is scaling up production: An automatic labeler is a non-negotiable tool for meeting higher demand and fulfilling large orders efficiently.

- If your primary focus is improving brand perception: The machine's ability to deliver a flawless, consistent finish is essential for building a premium brand identity.

- If your primary focus is controlling operational costs: The long-term savings from reduced labor and eliminated errors will provide a clear and measurable return on the initial investment.

Ultimately, adopting an automated labeler is about transforming your labeling process from a production bottleneck into a powerful competitive advantage.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Operational Efficiency | Drastically increases throughput and optimizes workflow. |

| Financial Impact | Reduces long-term labor costs and minimizes expensive rework. |

| Brand Integrity | Ensures flawless, consistent label application for market appeal. |

| Considerations | Requires upfront investment and technical maintenance. |

Ready to transform your honey packaging line? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, high-performance labeling solutions. Our wholesale-focused operations ensure you get the reliable equipment you need to scale production, enhance your brand, and reduce costs. Contact HONESTBEE today to find the perfect labeling machine for your business!

Visual Guide

Related Products

- Automatic In-Line Round Bottle Labeling Machine

- Semi Automatic Round Bottle Labeling Machine

- Professional Thermostatic Conical Honey Melter

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- How do automated filling and labeling systems facilitate quality traceability in honey packaging? Optimize Compliance

- What is the importance of high-quality printing and documentation in honey production? Elevate Your Brand & Value

- Why are professional logo design and comprehensive labeling essential for honey? Boost Your Retail Market Success

- Why is automatic labeling equipment critical for the packaging process of certified regional honey? Master Compliance

- Why is it essential to integrate a high-performance automatic labeling system? Secure Trust and Compliance in Honey

- Why is specialized honey storage and packaging equipment essential for exports? Secure Global Market Access

- What role do professional packaging containers and labeling materials play in the market transformation of honey products?

- What impact does a honey bottle labeling machine have on production costs? Lower Labor & Waste for Higher Profits