When it comes to bottling your honey, the choice between manual and automated filling hinges on three critical factors: speed, consistency, and scale. Automated filling systems are designed for high-volume, rapid production with minimal variation between jars. In contrast, manual filling offers a low-cost, flexible solution ideal for smaller operations where precision is secondary to craftsmanship.

The decision is not about which method is inherently "better," but which tool is right for your specific goals. This is a strategic choice that balances initial investment against long-term operational efficiency and brand identity.

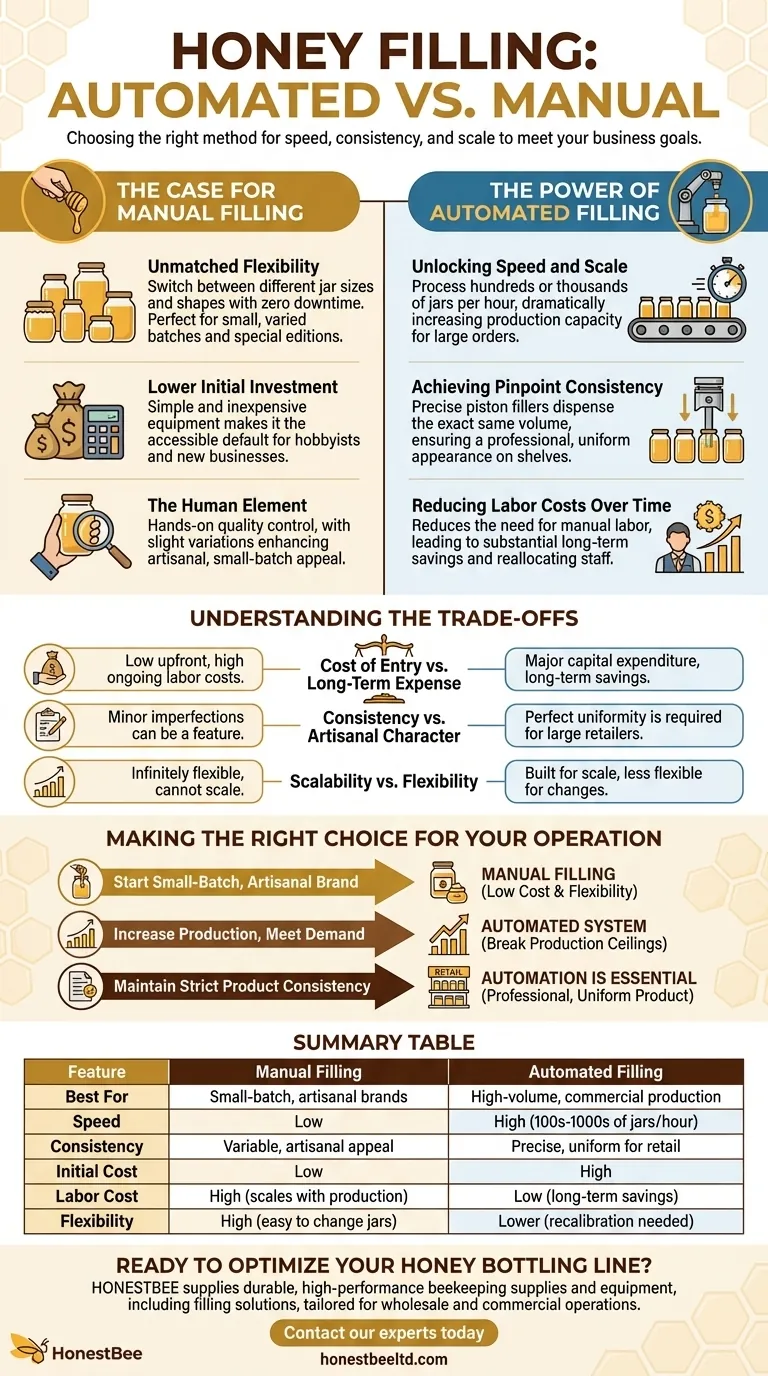

The Case for Manual Filling

For many beekeepers and artisanal producers, manual filling is the most logical and accessible starting point. It provides complete control over the process with a minimal financial barrier to entry.

Unmatched Flexibility

Manual filling allows you to switch between different jar sizes, shapes, and closure types with zero downtime. This is perfect for handling small, varied batches or special editions of unique honey varietals.

Lower Initial Investment

The primary advantage of manual filling is its low cost. The equipment needed is simple and inexpensive, making it the default choice for hobbyists, farm stands, and new businesses operating on a tight budget.

The Human Element

While less consistent than a machine, manual filling allows for hands-on quality control. You can personally inspect each jar, and the slight variations in fill level can even enhance the product's artisanal, small-batch appeal.

The Power of Automated Filling

As an operation grows, manual filling quickly becomes a bottleneck. Automation addresses this by introducing speed, precision, and efficiency that are impossible to achieve by hand.

Unlocking Speed and Scale

An automated filling line can process hundreds or thousands of jars per hour, dramatically increasing your production capacity. This leap in efficiency is essential for meeting the demands of larger orders and wholesale partners.

Achieving Pinpoint Consistency

Automated systems use precise mechanisms like piston fillers to dispense the exact same volume of honey into every single jar. This eliminates over-fills that waste product and under-fills that can damage consumer trust, ensuring a professional and uniform appearance on the retail shelf.

Reducing Labor Costs Over Time

While the initial investment in an automated filler is significant, it reduces the need for manual labor dedicated to the repetitive task of bottling. This can lead to substantial long-term savings and allows you to reallocate staff to more valuable activities.

Understanding the Trade-offs

Choosing a filling method requires an objective look at the compromises involved. Each approach has clear benefits and limitations that will directly impact your business.

Cost of Entry vs. Long-Term Expense

Manual filling has a very low upfront cost but high, ongoing labor costs that scale with production. Automation is the reverse: a major capital expenditure that pays for itself over time through reduced labor and increased output.

Consistency vs. Artisanal Character

The perfect uniformity of automated filling is a requirement for most large retailers. However, some brands build their identity around a handcrafted image, where the minor imperfections of manual filling can be a feature, not a bug.

Scalability vs. Flexibility

Automation is built for scale but can be less flexible. Changing jar sizes or product types may require significant time for recalibration. Manual methods are infinitely flexible but simply cannot scale to high-volume production.

Making the Right Choice for Your Operation

Align your equipment choice with the specific needs and future vision of your honey business.

- If your primary focus is starting a small-batch, artisanal brand: Manual filling offers the low cost and flexibility you need to get started and experiment.

- If your primary focus is increasing production to meet growing demand: An automated system is the most effective way to break through production ceilings and improve efficiency.

- If your primary focus is maintaining strict product consistency for retail partners: Automation is essential for delivering the professional, uniform product that wholesalers and supermarkets expect.

Ultimately, the right filling method is the one that best supports your operational scale and business goals.

Summary Table:

| Feature | Manual Filling | Automated Filling |

|---|---|---|

| Best For | Small-batch, artisanal brands | High-volume, commercial production |

| Speed | Low | High (100s-1000s of jars/hour) |

| Consistency | Variable, artisanal appeal | Precise, uniform for retail |

| Initial Cost | Low | High |

| Labor Cost | High (scales with production) | Low (long-term savings) |

| Flexibility | High (easy to change jars) | Lower (recalibration needed) |

Ready to Optimize Your Honey Bottling Line?

Whether you're a commercial apiary scaling up or a distributor supplying equipment, the right filling system is key to efficiency and profitability. HONESTBEE supplies durable, high-performance beekeeping supplies and equipment, including filling solutions, tailored for wholesale and commercial operations.

Contact our experts today to discuss how we can help you select the perfect equipment to meet your production goals and boost your bottom line.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- 10L Stainless Steel Electric Honey Press Machine

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What technical advantages do industrial-grade honey filling machines provide? Boost Your Commercial Honey Quality

- How do industrial honey filling machines assist honey producers? Unlock Retail Success & Higher Margins

- What are the advantages of integrating professional-grade honey-filling machines? Scaling Your Production for Growth

- What are the key features of honey-filling machines? Optimize Your Apiary with Precision Filling Technology

- How do automatic quantitative filling systems ensure consistency in honey? Achieve Perfect Flavored Honey Precision

- How does automatic filling equipment ensure the quality of honey collected from wild floral sources? | HONESTBEE Guide

- What equipment is used for bottling honey cleanly and efficiently? Professional Filling Solutions for Every Scale

- Why is the use of industrial-grade automatic filling machines significant for Eucalyptus honey? Ensure Quality & Purity