At its core, the honey extraction process is a systematic method for removing liquid honey from the beeswax honeycomb where bees have stored it. The primary stages involve harvesting the honeycomb frames from the hive, removing the protective wax cappings from the cells, extracting the honey, filtering out impurities, and finally, bottling the finished product.

The fundamental goal of honey extraction is to separate pure, liquid honey from the beeswax comb while maintaining its quality and cleanliness. The method you choose—whether using a mechanical extractor or a simpler crush and strain technique—will depend on your scale, budget, and long-term beekeeping goals.

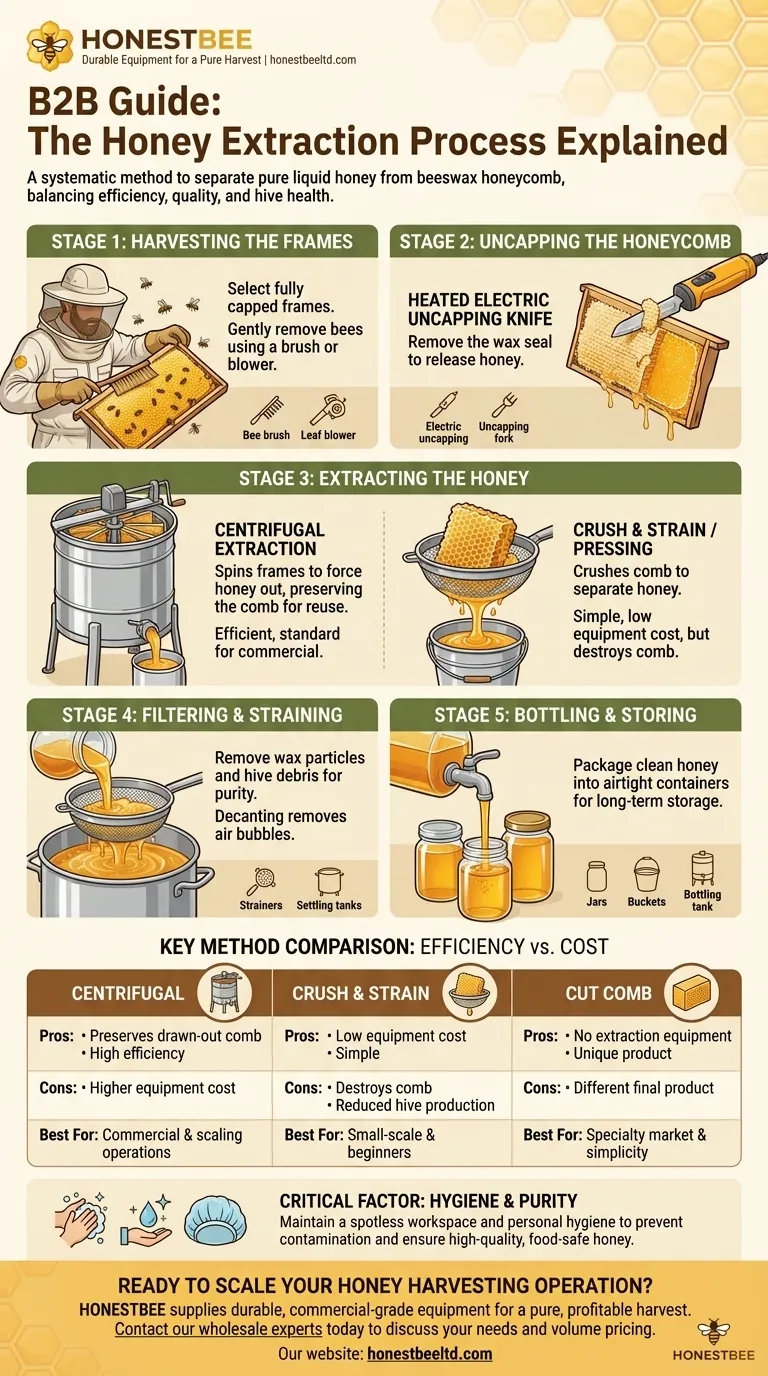

The Five Core Stages of Honey Extraction

Each stage of the extraction process serves a specific purpose, moving the honey from a protected state inside the hive to a clean, usable form.

Stage 1: Harvesting the Honey Frames

The process begins in the apiary by selecting the right frames. You are looking for frames where the bees have filled the cells with honey and sealed them with a layer of white beeswax, known as capping.

Once selected, bees must be gently removed from the frames. This is often done with a tool like a bee brush or a low-power leaf blower.

Stage 2: Uncapping the Honeycomb

Before honey can be removed, you must break the seal the bees created. This crucial step is called uncapping.

This involves carefully removing the thin wax cappings from the honeycomb cells. Common tools for this include a heated electric knife, a specialized uncapping fork, or a serrated knife.

Stage 3: Extracting the Honey from the Comb

This is where the honey is physically separated from the comb. There are two primary methods for accomplishing this.

The most common is centrifugal extraction, which uses a machine called a honey extractor. Frames are placed inside, and the extractor spins them, forcing the honey out of the cells through centrifugal force.

The alternative is the crush and strain (or pressing) method. This involves crushing the entire comb and then straining the resulting mixture of honey and wax through a filter to separate them.

Stage 4: Filtering and Straining

No matter the extraction method, the raw honey will contain small particles of beeswax and other hive debris.

The honey is poured through one or more filters or strainers to remove these impurities. Some beekeepers also let the honey sit in a tank in a process called decanting, which allows air bubbles and finer impurities to rise to the surface for skimming.

Stage 5: Bottling and Storing

Once the honey is clean and pure, it is ready for its final step. The honey is poured into clean, airtight jars for storage or sale. Properly sealed honey is a stable food that can last indefinitely.

Understanding the Trade-offs: Key Extraction Methods

The choice between extraction methods comes with significant trade-offs that affect your equipment cost and the health of your bee colony.

Centrifugal Extraction

This method is highly efficient and is the standard for most beekeepers beyond the hobbyist level.

Its greatest advantage is that it preserves the drawn-out honeycomb. The empty frames can be returned to the hive, saving the bees the immense energy required to build new wax comb from scratch.

Crush and Strain / Pressing

This technique is simple and requires very little specialized equipment, making it ideal for first-time beekeepers or those with only one or two hives.

The major drawback is that it destroys the beeswax comb. The bees must expend significant time and resources to rebuild it, which can reduce their honey production in the short term.

The Cut Comb Method

A third option avoids extraction entirely. Cut comb involves cutting out sections of the sealed honeycomb and packaging them directly. This is the simplest way to harvest honey but results in a different final product than liquid honey.

A Critical Factor: Maintaining Purity and Cleanliness

Honey is a food product, and maintaining strict hygiene is non-negotiable to prevent contamination and ensure a high-quality result.

Prepare Your Workspace

Your extraction area must be impeccably clean and free of dirt, dust, and insects. All surfaces and equipment should be washed thoroughly before you begin.

Ensure Personal Hygiene

Keep your hands and fingernails clean, tie back long hair, and avoid activities like smoking that could introduce contaminants. Treat the process with the same care you would any other food preparation.

Making the Right Choice for Your Goal

Your approach to honey extraction should align with your beekeeping philosophy and resources.

- If your primary focus is long-term hive health and efficiency: Centrifugal extraction is the superior choice because it allows you to reuse the valuable honeycomb.

- If your primary focus is a small-scale harvest with minimal investment: The crush and strain method is the most accessible and cost-effective way to get started.

- If your primary focus is simplicity and a natural product: Offering cut comb requires no extraction equipment and provides a unique product for consumption.

Ultimately, a successful extraction is a rewarding process that transforms the hard work of your bees into a pure, delicious, and shelf-stable food.

Summary Table:

| Stage | Key Action | Common Tools/Methods |

|---|---|---|

| 1. Harvesting | Select and remove capped frames from the hive. | Bee brush, leaf blower. |

| 2. Uncapping | Remove wax seals from honeycomb cells. | Uncapping knife, fork. |

| 3. Extracting | Separate honey from the comb. | Centrifugal extractor, Crush & strain. |

| 4. Filtering | Remove wax particles and debris. | Strainers, settling tanks. |

| 5. Bottling | Pour pure honey into containers for storage. | Jars, buckets, bottling tank. |

Ready to Scale Your Honey Harvesting Operation?

For commercial apiaries and beekeeping equipment distributors, efficiency and equipment reliability are paramount. HONESTBEE supplies the durable, high-capacity extraction equipment—from uncapping tools to commercial-grade honey extractors—that your business depends on for a pure, profitable harvest.

Contact our wholesale experts today to discuss your equipment needs and volume pricing.

Visual Guide

Related Products

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

People Also Ask

- What are the technical contributions of Centrifugal Honey Extractors? Maximize Harvest Efficiency & Reuse Your Combs

- How does a Centrifugal Honey Extractor contribute to the efficiency of the honey harvesting process? Maximize Your Yield

- How do electric and manual honey extractors compare? Choose the Best Tool for Your Apiary Efficiency

- Can a centrifugal honey extractor be used with a top bar hive? Why the Crush and Strain Method is Your Best Bet

- How do centrifugal honey extractors achieve high-efficiency extraction? Master the Science of Comb Preservation