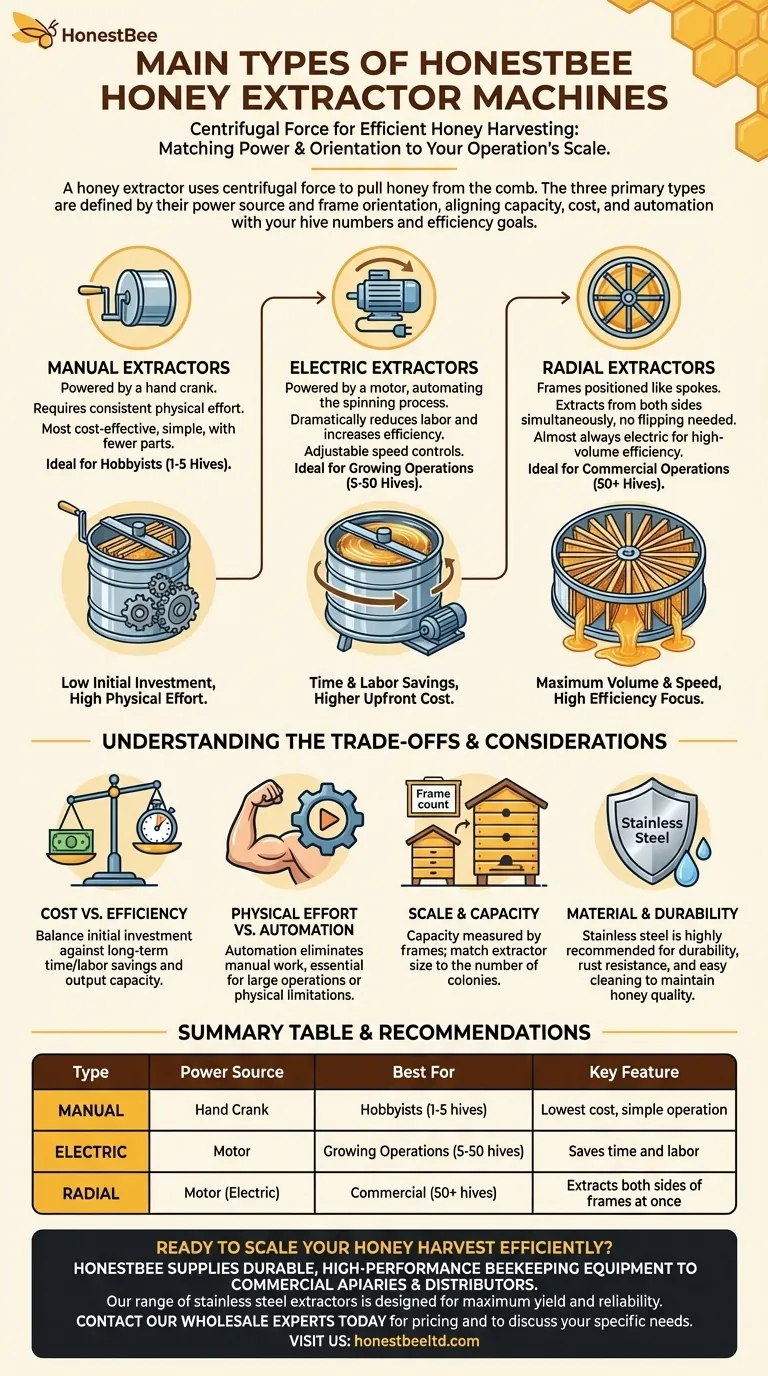

At its core, a honey extractor is a machine that uses centrifugal force to pull honey from the comb. The three primary types are defined by their power source and frame orientation: manual extractors, which you power by hand; electric extractors, which use a motor; and radial extractors, which arrange frames for maximum speed and are almost always electric. Choosing the right one depends entirely on the scale of your beekeeping operation.

The decision is not about finding the "best" extractor, but about aligning the machine's capacity, cost, and level of automation with your specific number of hives and your goals for efficiency.

The Three Core Extractor Designs

The fundamental differences between honey extractors come down to how they are powered and how they hold the honeycomb frames. These two factors determine the machine's speed, labor requirement, and suitability for your apiary.

Manual Extractors

A manual honey extractor is powered by a hand crank. This requires consistent physical effort to spin the internal basket fast enough to extract the honey.

They are the most cost-effective option, making them the standard choice for hobbyists or beekeepers with only a few hives. Their simplicity also means there are fewer mechanical parts that can fail.

Electric Extractors

An electric honey extractor replaces the hand crank with a motor. This automates the spinning process, dramatically reducing labor and increasing efficiency.

These machines are ideal for medium to large-scale operations where manually cranking for hours is impractical. Many models offer adjustable speed controls, giving you more precise command over the extraction process.

Radial Extractors

The term radial extractor refers to how the frames are positioned inside the drum. The frames are arranged like spokes on a wheel, with the top bar facing outward.

This design allows honey to be extracted from both sides of the comb simultaneously, eliminating the need to stop and flip the frames. Because of their focus on high-volume efficiency, radial extractors are almost always electric and are the preferred choice for large and commercial beekeeping operations.

Understanding the Trade-offs

Selecting an extractor involves balancing initial cost against long-term efficiency and labor. What is a smart investment for one beekeeper is an unnecessary expense for another.

Cost vs. Efficiency

A manual extractor represents the lowest initial investment, but its efficiency is limited by your physical stamina. An electric model costs more upfront but provides significant savings in time and labor, increasing your overall output capacity.

Physical Effort vs. Automation

The primary benefit of an electric extractor is the near-elimination of physical work. For beekeepers with many hives or physical limitations, automation is not a luxury—it's a necessity for a sustainable harvesting process.

Scale and Capacity

An extractor's capacity is measured by the number of frames it can hold. A small 2-frame manual extractor is perfect for a backyard beekeeper. In contrast, a commercial operation with 200 or more colonies requires a large radial extractor that can process dozens of frames at once to be viable.

Material and Durability

Regardless of type, stainless steel construction is highly recommended. It is far more durable than plastic, resists rust, and is much easier to clean and sanitize, which is critical for maintaining honey quality.

Making the Right Choice for Your Operation

Choose the extractor that directly matches the scale and ambition of your beekeeping.

- If your primary focus is hobby beekeeping (1-5 hives): A simple, cost-effective manual extractor is the most practical and economical choice.

- If your primary focus is a growing operation (5-50 hives): An electric tangential or a small electric radial extractor will provide the efficiency you need to save significant time and labor.

- If your primary focus is a commercial operation (50+ hives): A large-capacity, electric radial extractor is the only tool that can handle the required volume and speed.

Ultimately, the right extractor is a tool that empowers you to harvest your honey efficiently, without becoming a bottleneck in your operation.

Summary Table:

| Type | Power Source | Best For | Key Feature |

|---|---|---|---|

| Manual | Hand Crank | Hobbyists (1-5 hives) | Lowest cost, simple operation |

| Electric | Motor | Growing Operations (5-50 hives) | Saves time and labor |

| Radial | Motor (Electric) | Commercial (50+ hives) | Extracts both sides of frames at once |

Ready to scale your honey harvest efficiently?

At HONESTBEE, we supply durable, high-performance beekeeping equipment to commercial apiaries and distributors. Our range of honey extractors, including robust stainless steel models, is designed for maximum yield and reliability in demanding environments.

Let us help you select the perfect extractor for your operation's volume and goals. Contact our wholesale experts today for pricing and to discuss your specific needs.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

People Also Ask

- What are the advantages of automated honey extractors in terms of time efficiency? Boost Your Harvest Speed

- Should I get a manual or electric honey extractor? Choose the right extractor for your beekeeping scale.

- What are radial honey extractors and what are their features? Maximize Your Honey Harvest Efficiency

- What are the two common types of honey extractors? Choose the Right Extractor for Your Apiary

- What is a machine used to remove honey from frames? The Complete Guide to Honey Extractors