When choosing honey packaging, you must evaluate the container material, its form factor, your production scale, and your target market. The decision balances the premium appeal of glass jars, the versatility of plastic, and the convenience of squeeze bottles or pouches against the operational costs of filling, capping, and labeling.

Your choice of packaging is not just about holding honey; it is a strategic decision that defines your brand's identity, operational efficiency, and connection with your customer. The right container serves as a crucial marketing tool that protects the product while communicating its value.

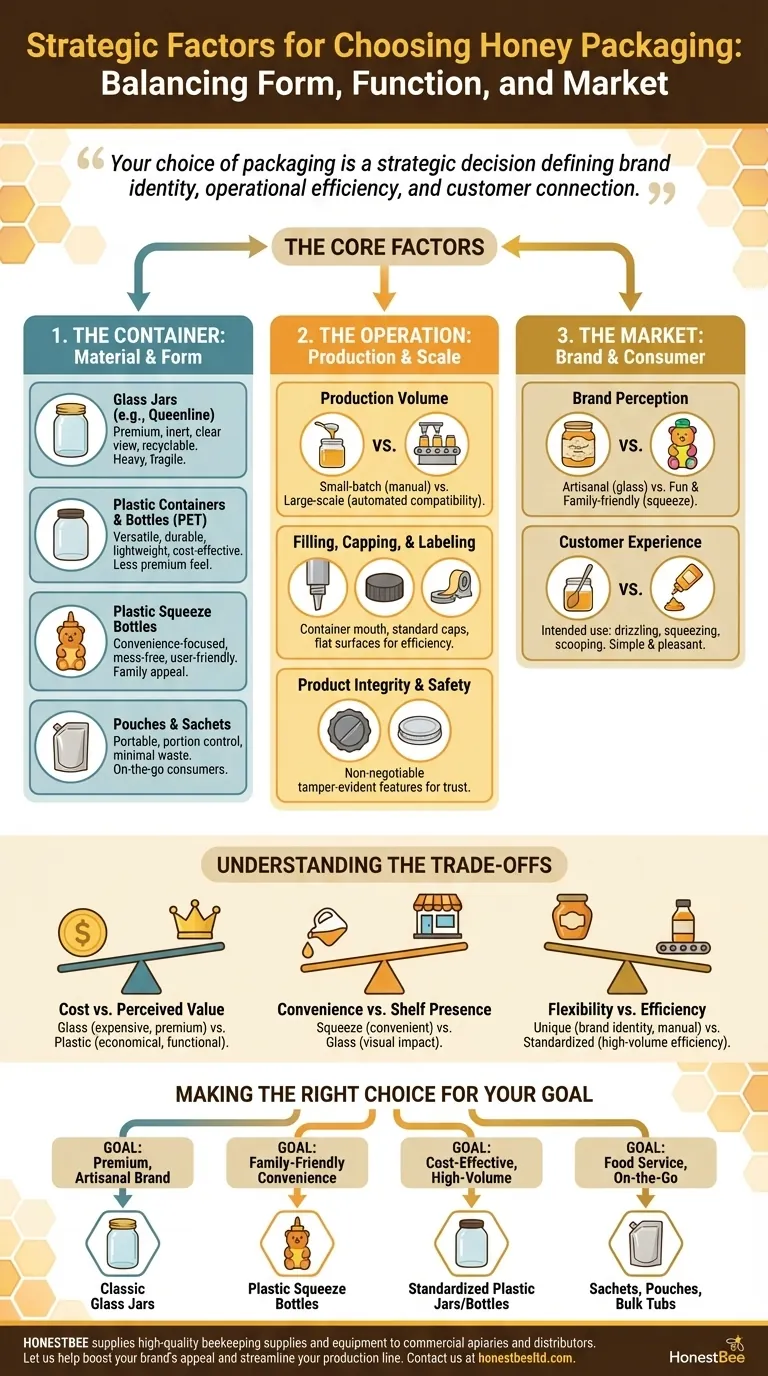

The Core Factors in Your Packaging Decision

Choosing the right honey packaging requires a holistic view. It's a system where the container, your production process, and your market strategy must align. We can break this down into three critical areas.

1. The Container: Material and Form

The physical container is the most visible part of your product and makes an immediate statement about its quality and intended use.

Glass Jars (e.g., Queenline)

Glass is the traditional, premium choice. It is inert, impermeable, and offers a pristine view of the honey, signaling high quality and purity to the customer. It is also infinitely recyclable. However, glass is heavier and more fragile, increasing shipping costs and risk of breakage.

Plastic Containers & Bottles

Plastic (often PET) is a versatile and durable option. It's lightweight, shatter-resistant, and can be molded into various shapes, making it a cost-effective and practical choice for shipping and retail. Clarity can rival glass, but it may not convey the same premium feel.

Plastic Squeeze Bottles

This form factor prioritizes user convenience. Squeeze bottles are ideal for families and everyday use, allowing for easy, mess-free dispensing. They are inherently user-friendly and appeal to a market focused on practicality over artisanal presentation.

Pouches and Sachets

Flexible pouches and single-serving sachets are excellent for portability and portion control. They are lightweight and minimize packaging waste, making them a strong choice for on-the-go consumers, food service applications, or product samples.

2. The Operation: Production and Scale

Your packaging choice directly impacts your production line. A container that is difficult to fill or cap can create significant bottlenecks and increase labor costs.

Production Volume

The number of units you plan to produce is a primary driver. A small-batch apiary can manually fill and label unique jars, but a large-scale operation needs a container standardized for automated machinery.

Filling, Capping, and Labeling

Consider how your chosen container will work with equipment. Does the mouth opening allow for efficient filling? Is there a standard cap available? Does the container shape provide a flat, consistent surface for easy label application? Mismatches here lead to inefficiency and added expense.

Product Integrity & Safety

Tamper-evident seals are non-negotiable for building consumer trust and ensuring safety. Features like induction-sealed liners, shrink bands over the lid, or "pop-up" safety buttons on metal lids provide a clear visual indicator that the product is untouched.

3. The Market: Brand and Consumer

Ultimately, your packaging must appeal to your target customer. It is your product’s first and most direct form of communication on a crowded shelf.

Brand Perception

A classic glass queenline jar immediately communicates an artisanal, high-quality product. A brightly colored plastic squeeze bear appeals to a fun, family-oriented market. Your packaging must align with the story you want to tell about your honey.

Customer Experience

Think about how the end-user will interact with the product. Is it for drizzling over yogurt, squeezing into tea, or scooping out for a recipe? The form of the container should make that intended use as simple and pleasant as possible.

Understanding the Trade-offs

There is no single "best" packaging; every choice involves balancing competing priorities. Being aware of these trade-offs is key to making an informed decision.

Cost vs. Perceived Value

Glass is generally the most expensive option in terms of both material and shipping weight. However, it commands a higher price point and conveys a premium image that can justify the cost. Plastic is more economical but may not stand out as a luxury product.

Convenience vs. Shelf Presence

A plastic squeeze bottle is highly convenient for the consumer at home but may lack the visual impact and classic aesthetic of a well-shaped glass jar on a retail shelf. Your choice depends on whether you prioritize ease of use or point-of-sale appeal.

Flexibility vs. Efficiency

Unique, custom-shaped containers can create a strong brand identity and help you stand out. However, they almost always complicate the automation process, making them better suited for smaller, manual operations than for high-volume production lines seeking maximum efficiency.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary business objective.

- If your primary focus is a premium, artisanal brand: Choose classic glass jars to signal quality, purity, and a traditional aesthetic.

- If your primary focus is family-friendly convenience: Select plastic squeeze bottles for their durability, ease of use, and mess-free dispensing.

- If your primary focus is cost-effective, high-volume production: Use standardized plastic jars or bottles that are compatible with efficient, automated filling and labeling equipment.

- If your primary focus is the food service or on-the-go market: Opt for single-serve sachets, pouches, or bulk plastic tubs for portability and portion control.

By aligning your container with your operational capabilities and market goals, your packaging becomes your most powerful silent salesperson.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Container Material | Glass (premium), Plastic (versatile), Squeeze Bottles (convenient), Pouches (portable) |

| Production Scale | Small-batch (manual) vs. Large-scale (automated machinery compatibility) |

| Target Market | Artisanal (glass), Family-friendly (squeeze bottles), Food service (sachets/pouches) |

| Key Trade-offs | Cost vs. Perceived Value, Convenience vs. Shelf Presence, Flexibility vs. Efficiency |

Ready to find the perfect honey packaging solution for your operation? HONESTBEE supplies high-quality beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through our wholesale-focused operations. We can help you select the right containers to boost your brand's appeal and streamline your production line. Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Hexagonal Glass Honey Jars with Metal Lug Caps Elegant Versatile Packaging

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Classic Drum Shaped Glass Honey Jar with Airtight Lid

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

- Natural Wood Honey Dipper for Tea Coffee and Desserts

People Also Ask

- What is done with the honey after extraction and filtering? From Purification to Perfect Packaging

- What are the primary functional benefits of high-standard glass packaging for honey? Protect Purity and Brand Value

- How many jars of honey do you get from a hive? Unlock Sustainable Harvesting Secrets

- How does the appearance of glass jar packaging affect the sales and perception of honey? Boost Your Premium Brand Value

- Why are transparent glass containers utilized in honey storage stability studies? Simulating Real-World Quality Decay