Selecting the right honey filling machine requires a critical evaluation of your product's specific characteristics, your required production volume, and the level of automation that fits your business. The key factors are honey viscosity, container type and size, desired output speed, and the trade-offs between semi-automatic and fully automatic systems.

Choosing a honey filler is less about finding the "best" machine and more about finding the right machine for your specific operational reality. A mismatch in viscosity handling, production scale, or long-term maintainability can create significant bottlenecks and unforeseen costs.

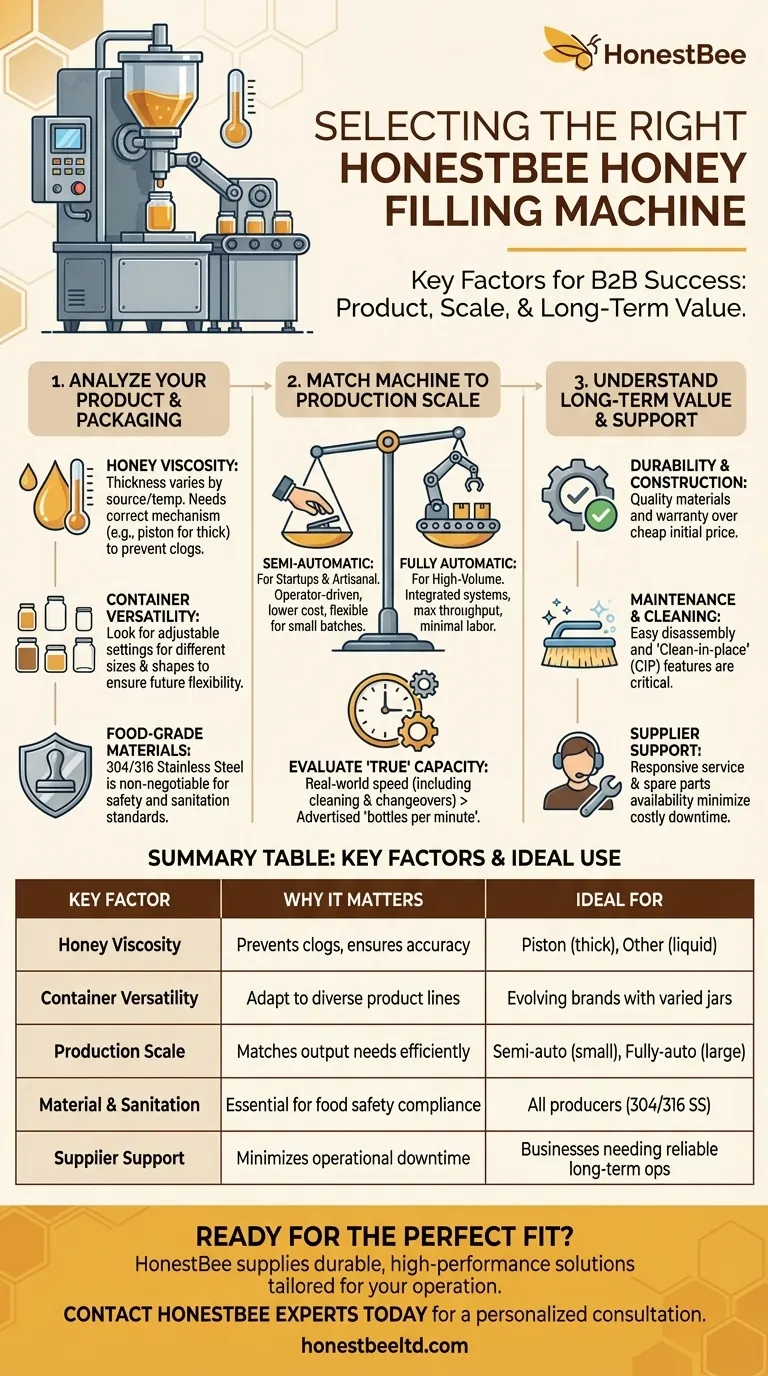

Analyze Your Product and Packaging First

Before evaluating any machine, you must have a complete understanding of what you are putting into the bottles. The product and its container dictate the fundamental requirements of the filling technology.

The Challenge of Honey's Viscosity

Honey's thickness, or viscosity, varies dramatically based on its floral source, temperature, and moisture content. This is the single most important product characteristic to consider.

A machine must be able to handle your specific product's viscosity without causing clogs or delivering inaccurate fill volumes. Thicker, crystallized honey may require a piston filler, while thinner, more liquid honey might work well with a different mechanism.

Container Size and Shape Versatility

Your machine must accommodate your current and future container lineup. A lack of flexibility can lock you into a limited range of packaging.

Look for adjustable settings for container height and fill volume. This versatility allows you to handle everything from small sample jars to large bulk containers, giving your business agility.

Ensuring Food Safety with Material Compatibility

All parts that come into contact with the honey must be made from food-grade materials, most commonly 304 or 316 stainless steel.

This is non-negotiable. It prevents corrosion, ensures the machine can be properly sanitized, and is crucial for meeting food safety standards and maintaining the purity of your product.

Match the Machine to Your Production Scale

The right machine for a small startup is entirely different from the one needed for a large industrial operation. Your choice must align with your current output needs and realistic growth plans.

Semi-Automatic: For Startups and Artisanal Producers

These machines require an operator to place containers under the fill head and typically initiate the fill cycle with a foot pedal or button.

They are ideal for small businesses due to their lower initial investment, smaller footprint, and flexibility for running small, diverse batches.

Fully Automatic: For High-Volume Operations

These are integrated systems that manage the entire process from feeding empty containers to filling and sometimes capping, all with minimal operator intervention.

They are essential for large factories and co-packers focused on maximizing throughput and minimizing labor costs per unit.

Evaluating True Production Capacity

Do not be swayed solely by the advertised "bottles per minute." This metric often represents an ideal scenario.

Consider the real-world speed, factoring in the time required for product changeovers, cleaning cycles, and potential maintenance. A machine that is easy to operate and set up will often deliver higher true output by reducing training time and user error.

Understanding the Trade-offs and Long-Term Costs

The initial purchase price is only one part of the total cost of ownership. Durability, maintainability, and supplier support are critical factors that impact your operational efficiency and long-term profitability.

The Hidden Costs of Poor Construction

A cheaper machine might seem appealing, but poor-quality motors, seals, or flimsy construction can lead to frequent breakdowns and inconsistent fills.

Durability, often indicated by the quality of materials, the manufacturer's warranty, and customer reviews, is a far better indicator of long-term value.

The Importance of Maintenance and Cleaning

Honey is sticky and can be challenging to clean. A machine designed for easy disassembly and cleaning (known as "clean-in-place" or CIP features) is critical for sanitation.

Efficient cleaning prevents cross-contamination between different honey varietals and reduces labor costs associated with sanitation shifts.

Evaluating Supplier Support and Spare Parts

Your machine is only as reliable as the support behind it. A breakdown can halt your entire production line.

Ensure the supplier offers responsive customer service and can guarantee the availability of spare parts like seals and nozzles. Good documentation and support for repairs will minimize costly downtime.

Making the Right Choice for Your Goal

Your final decision should be a strategic one based on your specific business objectives.

- If your primary focus is launching a small, artisanal brand: Prioritize a flexible, semi-automatic machine made of food-grade stainless steel that is easy to clean and can handle various jar sizes.

- If your primary focus is scaling a growing business: Invest in a robust semi-automatic or entry-level automatic machine with proven durability and adjustable settings to accommodate increasing volume and packaging diversity.

- If your primary focus is maximizing industrial output: Select a high-speed, fully automatic system from a reputable supplier with a strong track record for reliability and comprehensive post-sales support.

By aligning the machine's capabilities with your specific product, scale, and long-term vision, you can make a confident investment that supports your business's efficiency and growth.

Summary Table:

| Key Factor | Why It Matters | Ideal For |

|---|---|---|

| Honey Viscosity | Determines filling mechanism to prevent clogs and ensure accuracy. | Piston fillers for thick honey; other types for liquid honey. |

| Container Versatility | Adjustable settings allow for different jar sizes and shapes. | Businesses with diverse or evolving product lines. |

| Production Scale | Matches machine speed and automation to your output needs. | Semi-auto for startups; Fully-auto for high-volume operations. |

| Material & Sanitation | Food-grade stainless steel (304/316) is essential for safety. | All producers requiring compliance with food safety standards. |

| Supplier Support | Access to spare parts and service minimizes costly downtime. | Every business focused on long-term, reliable operation. |

Ready to invest in a honey filling machine that perfectly fits your operation?

At HONESTBEE, we supply durable, high-performance beekeeping equipment and honey filling solutions tailored for commercial apiaries and distributors. We understand the critical factors of viscosity handling, production speed, and food-grade safety. Let us help you select a machine that boosts your efficiency and supports your growth.

Contact our experts today for a personalized consultation and discover the right equipment for your business.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- How does honey filling machinery contribute to the industrialization of honey processing? Scaling Global Production

- Why is the use of industrial automatic honey filling machines necessary? Secure Premium Forest Honey Quality

- What role do honey filling machines play in enhancing the value of organic honey? Protect Purity and Scale Your Brand

- Why is high-capacity honey filling machinery necessary for Giant Honey Bees? Solve the Apis dorsata Volume Crisis

- How do industrial honey-filling machines contribute to the value chain? Unlock Commercial Success for Bee Products

- What challenges do high-efficiency honey filling machines address? Optimize Your Export Standards and Profitability

- How do honey filling machines and specialized packaging impact production? Boost Efficiency & Market Value

- Why exclude container weight in honey filling? Master Net Mass Accuracy with Industrial Machinery