In short, after honey is packaged, it enters the global supply chain. The product is then marketed and distributed to two primary destinations: large-scale food industries that use it as an ingredient, and the retail sector for direct sale to consumers. This process transforms the packaged good into a market-ready commodity.

The packaging process isn't the end of the line; it's the critical branching point where honey is channeled into distinct international pathways, either for industrial use in other food products or for direct placement on store shelves.

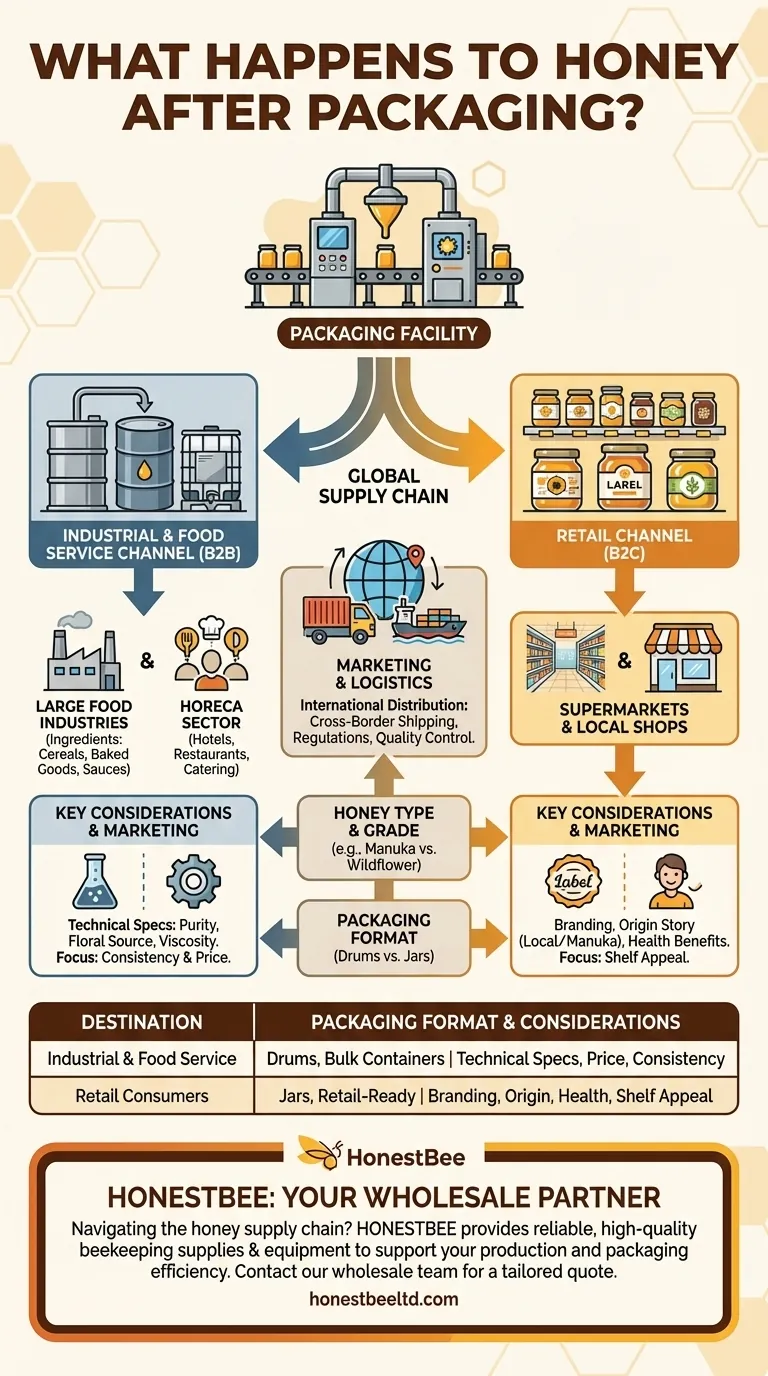

The Two Primary Distribution Channels

Once sealed in jars or industrial containers, honey embarks on one of two distinct journeys. The type of packaging often dictates its destination, separating the bulk supply chain from the consumer-facing one.

The Industrial & Food Service Channel

A significant portion of honey is packaged in large drums or containers for business-to-business (B2B) sales. These are not the jars you see in a grocery store.

The primary recipients are large food industries. These companies purchase honey in bulk to use as a key ingredient in other products, such as cereals, baked goods, sauces, and beverages.

Another major destination is the Horeca sector (Hotels, Restaurants, and Catering). These businesses use honey for food preparation and service, requiring larger quantities than a typical household.

The Retail Channel

This is the most familiar path for consumers. Honey is packaged in retail-ready jars using dedicated packaging lines.

From the packaging facility, these jars are distributed to wholesalers, regional distribution centers, and finally to supermarkets and local shops. Marketing plays a crucial role here, with branding, labeling, and shelf placement influencing consumer choice.

The Critical Role of Marketing and Logistics

Distribution is far more than just shipping. It involves a complex network of marketing efforts and logistical operations designed to move the product efficiently and effectively.

Differentiating the Marketing Approach

Marketing strategies differ significantly between the two channels. For industrial clients, marketing focuses on technical specifications: purity, floral source, color, and viscosity. Consistency and price are paramount.

For retail consumers, marketing focuses on brand story, origin (e.g., "local" or "Manuka"), and perceived health benefits. The label and jar design are essential marketing tools.

Navigating International Distribution

The reference to "international" distribution highlights the global nature of the honey market. This process involves complex logistics.

Producers must manage cross-border shipping, adhere to import/export regulations for different countries, and ensure quality control throughout transit. This global movement allows honey from one region to reach consumers and industries worldwide.

Understanding the Key Considerations

The final path of a batch of honey is not random. It is determined by several factors that are decided long before it reaches the end of a packaging line.

Impact of Honey Type and Grade

The floral source and quality of the honey often determine its final market. A rare, high-grade honey like Manuka is almost always destined for high-margin retail jars. In contrast, a common wildflower or clover honey might be directed toward industrial use where its flavor profile is valued for consistency in bulk.

The Influence of Packaging Format

As noted, the choice between a small glass jar and a 55-gallon drum is the most direct signal of intent. Modern facilities run separate, specialized lines for each format because they serve entirely different customers with unique logistical needs.

Making Sense of the Journey

Understanding these post-packaging steps provides a clear picture of how honey gets from the producer to your pantry or into your favorite foods.

- If you are a consumer buying a jar: The honey you hold has been through a retail-focused journey of branding, marketing, and distribution designed to appeal directly to you.

- If you are a business using honey as an ingredient: The honey you source arrives through an industrial supply chain where bulk efficiency, technical specifications, and consistent quality are the primary concerns.

Ultimately, the journey honey takes after packaging is a deliberate process that ensures this versatile natural product reaches the right customer in the right format.

Summary Table:

| Destination | Packaging Format | Key Considerations |

|---|---|---|

| Industrial & Food Service | Drums, Bulk Containers | Technical specs (purity, viscosity), price, consistency |

| Retail Consumers | Jars, Retail-ready Packaging | Branding, origin story, health benefits, shelf appeal |

Are you a commercial apiary or distributor navigating the honey supply chain?

HONESTBEE is your trusted partner for wholesale beekeeping supplies and equipment. We understand the critical importance of reliable, high-quality gear for both honey production and the packaging process that follows. Whether you're supplying the industrial sector or the retail market, our products support the efficiency and scale your operation demands.

Let's discuss how our equipment can enhance your productivity. Contact our wholesale team today to get a quote tailored to your commercial needs.

Visual Guide

Related Products

- Classic Drum Shaped Glass Honey Jar with Airtight Lid

- Hexagonal Glass Honey Jars with Metal Lug Caps Elegant Versatile Packaging

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- Why are glass containers prioritized over plastic for organic honey? Preserve Purity and Enzyme Activity

- What are the advantages of glass containers for honey? Elevate Quality and Market Value with Premium Packaging

- Why are professional-grade glass honey jars essential? Protect Product Quality and Build Market Credibility Today

- What are the advantages of glass honey containers? Preserve Purity and Flavor with Superior Storage Solutions

- What are the steps for preparing jars for bottling honey? Guide to Professional Honey Sanitation & Packaging