In simple terms, a 4-side seal package is a flat pouch or sachet that is sealed along all four of its edges. It is typically constructed from two flat pieces of flexible packaging material with the product placed in between. This method creates a completely enclosed, often hermetic, container.

The 4-side seal format is not just a packaging type; it's a strategic choice for when product protection and barrier integrity are non-negotiable. Its value lies in providing a superior hermetic seal, making it the industry standard for sensitive medical, pharmaceutical, and food products.

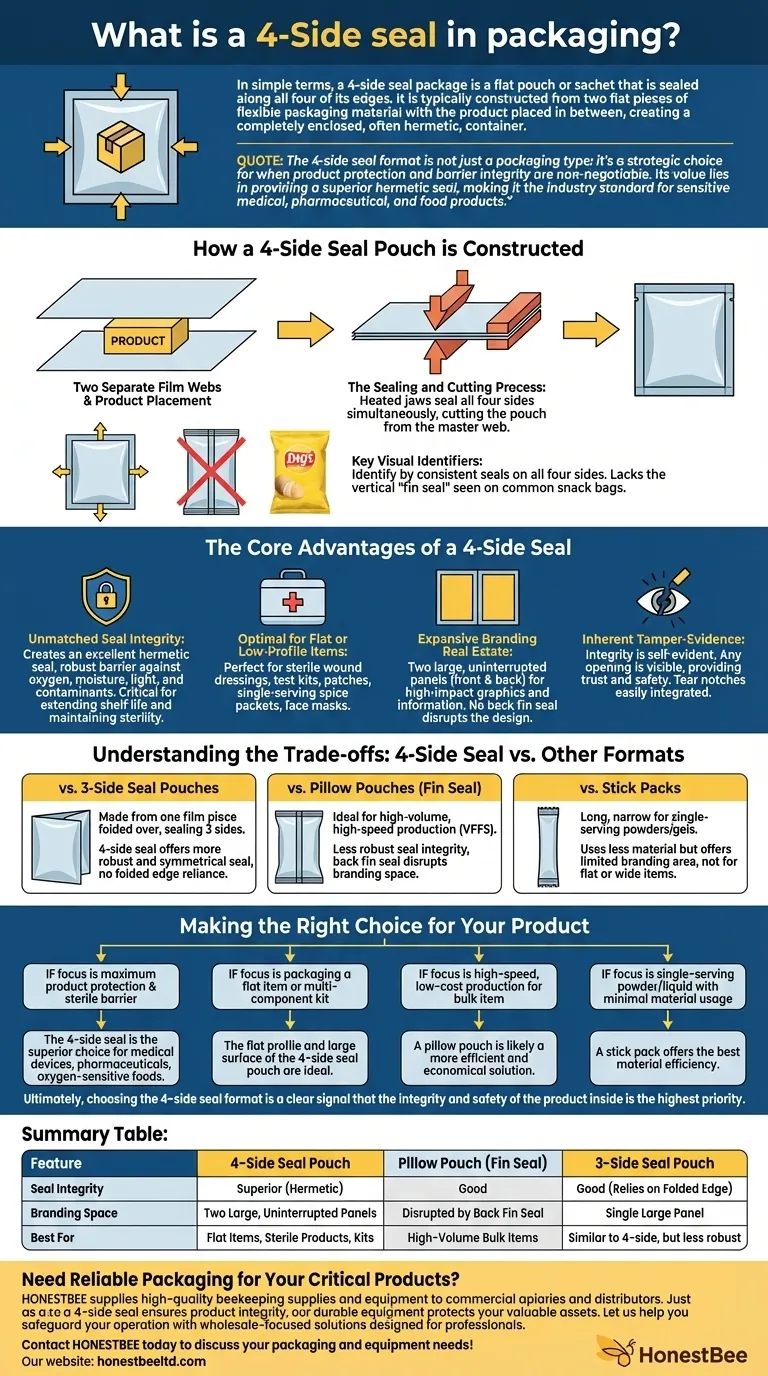

How a 4-Side Seal Pouch is Constructed

Understanding the construction of a 4-side seal pouch reveals why it is so reliable. The process is precise and fundamentally different from other common flexible packaging types.

Two Separate Film Webs

Unlike a pillow pouch that is formed from a single piece of film wrapped into a tube, a 4-side seal pouch begins as two separate, flat webs of material.

The product is placed between these two layers before they are sealed together.

The Sealing and Cutting Process

The two layers of film, with the product inside, are then sealed by heated jaws that press down on all four sides simultaneously. This action seals the pouch and typically cuts it from the master web of material in a single motion.

This process ensures that each of the four edges has a strong, independent seal.

Key Visual Identifiers

You can easily identify a 4-side seal pouch by its appearance. It is a flat pouch with a consistent seal on the top, bottom, left, and right sides.

Crucially, it lacks the vertical "fin seal" seen on the back of common snack bags (pillow pouches).

The Core Advantages of a 4-Side Seal

Choosing this format provides distinct benefits centered on protection, presentation, and user convenience.

Unmatched Seal Integrity

This is the primary reason to choose a 4-side seal. The complete, four-sided closure creates an excellent hermetic seal, providing a robust barrier against oxygen, moisture, light, and contaminants. This is critical for extending shelf life and maintaining product sterility.

Optimal for Flat or Low-Profile Items

The inherently flat profile makes it the perfect choice for products like sterile wound dressings, diagnostic test kits, transdermal patches, single-serving spice packets, or cosmetic face masks.

Expansive Branding Real Estate

Because it's made from two flat sheets, the pouch offers two large, uninterrupted panels (front and back) for high-impact graphics and essential information. There is no fin seal on the back to disrupt the design.

Inherent Tamper-Evidence

The integrity of the pouch is self-evident. Any puncture, tear, or opening of a seal is immediately visible to the end-user, providing a high degree of trust and safety. Tear notches are also easily integrated for convenient opening.

Understanding the Trade-offs: 4-Side Seal vs. Other Formats

No single packaging format is perfect for every application. The choice often involves balancing protection, cost, and production speed.

vs. 3-Side Seal Pouches

A 3-side seal pouch is made from one piece of film folded over, creating seals on the other three sides. While similar, the 4-side seal is often considered to have a more robust and symmetrical seal, as it doesn't rely on a folded edge.

vs. Pillow Pouches (Fin Seal)

Pillow pouches are ideal for high-volume products like potato chips because they can be formed and filled at very high speeds on vertical-form-fill-seal (VFFS) machines. However, their seal integrity is generally less robust than a 4-side seal, and the back fin seal disrupts branding space.

vs. Stick Packs

Stick packs are long, narrow pouches ideal for single-serving powders or gels. They use significantly less material than a 4-side seal pouch for a similar volume, but offer very limited surface area for branding and are not suitable for flat or wide items.

Making the Right Choice for Your Product

Selecting the correct packaging format requires aligning the package's strengths with your product's specific needs and your brand's goals.

- If your primary focus is maximum product protection and a sterile barrier: The 4-side seal is the superior choice for medical devices, pharmaceuticals, and oxygen-sensitive foods.

- If your primary focus is packaging a flat item or a multi-component kit: The flat profile and large surface of the 4-side seal pouch are ideal.

- If your primary focus is high-speed, low-cost production for a bulk item: A pillow pouch is likely a more efficient and economical solution.

- If your primary focus is a single-serving of powder or liquid with minimal material usage: A stick pack offers the best material efficiency.

Ultimately, choosing the 4-side seal format is a clear signal that the integrity and safety of the product inside is the highest priority.

Summary Table:

| Feature | 4-Side Seal Pouch | Pillow Pouch (Fin Seal) | 3-Side Seal Pouch |

|---|---|---|---|

| Seal Integrity | Superior (Hermetic) | Good | Good (Relies on Folded Edge) |

| Branding Space | Two Large, Uninterrupted Panels | Disrupted by Back Fin Seal | Single Large Panel |

| Best For | Flat Items, Sterile Products, Kits | High-Volume Bulk Items | Similar to 4-side, but less robust |

Need Reliable Packaging for Your Critical Products?

HONESTBEE supplies high-quality beekeeping supplies and equipment to commercial apiaries and distributors. Just as a 4-side seal ensures product integrity, our durable equipment protects your valuable assets. Let us help you safeguard your operation with wholesale-focused solutions designed for professionals.

Contact HONESTBEE today to discuss your packaging and equipment needs!

Visual Guide

Related Products

- Automatic Continuous Heat Sealing Machine

- HONESTBEE Pneumatic Flat Surface Labeling Machine

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

People Also Ask

- How do I choose a heat sealer? A Guide to Matching the Right Machine to Your Needs

- How do I choose a sealing machine? Find the Perfect Sealer for Your Packaging Line

- Why is it important to regularly inspect the seal on honey jars? Protect Purity and Extend Shelf Life Successfully

- What is a sealing machine? Protect Your Product Quality and Brand Reputation

- Why is specialized sealing equipment necessary for the packaging of bee pollen? Protect Quality and Shelf Life

- How do light-proof and anti-oxidation sealing machines maintain the quality of Royal Jelly? Protect Bioactive 10-HDA

- What is the role of a sealing mechanism in a packaging machine? Ensure Product Integrity and Long-Term Freshness

- Why is a vacuum packaging machine used for sealing bee drone comb samples? Ensure Optimal Nutrient Preservation