In this context, a "Syrup Maker" is not a person or a machine, but a specific type of long-term land management strategy. It refers to a plot of land, or a forest lot, that is intentionally designed and managed over decades with the primary goal of producing maple syrup once the trees reach maturity.

The term "Syrup Maker" describes a strategic approach to forestry, treating a stand of maple trees not just as a natural woodlot, but as a long-term agricultural asset cultivated specifically for sustainable sap collection and income generation.

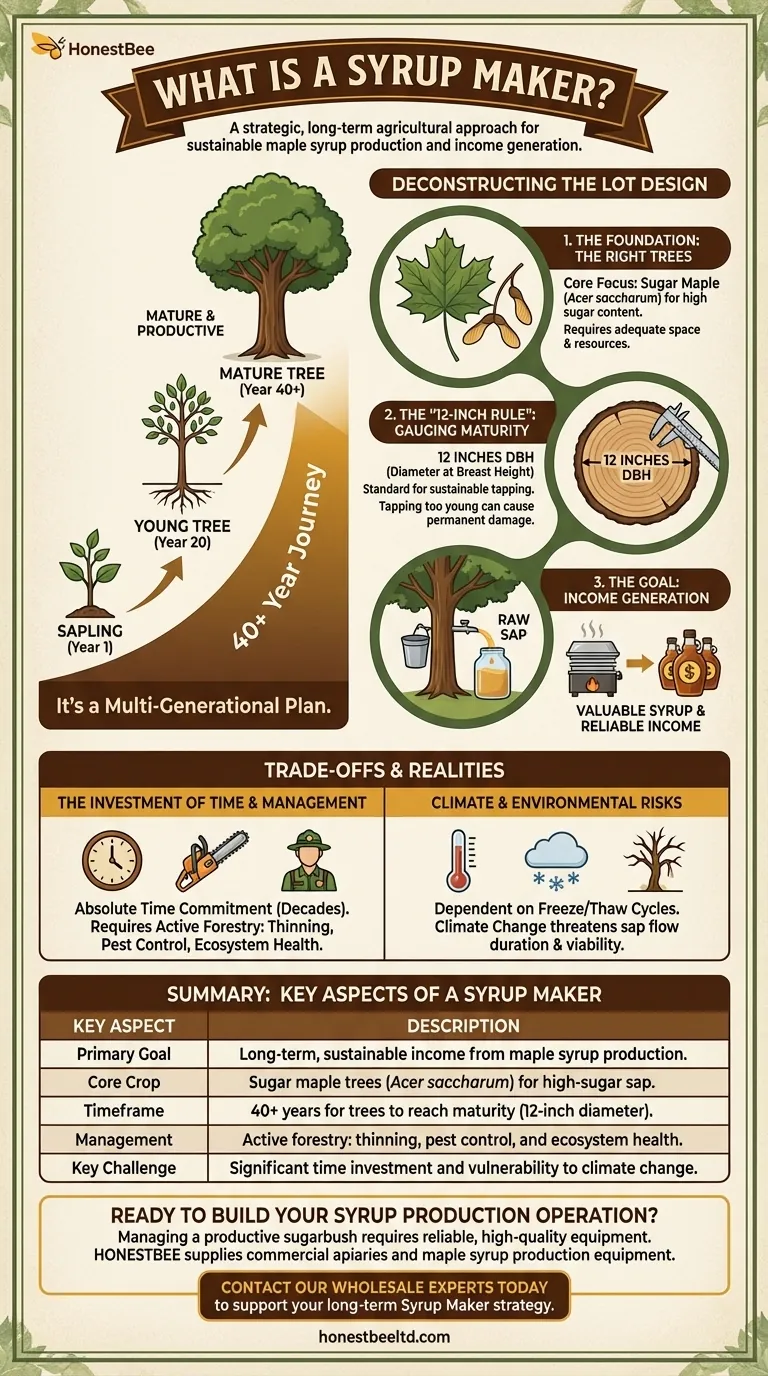

Deconstructing the "Syrup Maker" Lot Design

To understand this concept, it's best to think of a "Syrup Maker" lot like a vineyard or an apple orchard. It's a form of agriculture that requires patience, planning, and a deep understanding of the crop—in this case, the maple trees themselves.

It's a Long-Term Agricultural Plan

A Syrup Maker lot is the opposite of a short-term investment. Maple trees, particularly the prized sugar maple, can take 40 years or more to grow from a sapling to a size suitable for tapping.

This strategy requires a multi-generational outlook, focusing on creating a healthy, productive forest that will yield returns far in the future.

The Foundation: The Right Trees

The core of the design is the cultivation of specific tree species. While several maple species can be tapped, the sugar maple (Acer saccharum) is the most sought-after due to the high sugar content of its sap.

A well-managed lot will favor the growth of these high-value trees, ensuring they have adequate space, sunlight, and resources to thrive.

The "12-Inch Rule": Gauging Maturity

The reference to trees being mature enough at 12 inches refers to their diameter at breast height (DBH). This is the standard forestry measurement for a tree's trunk, taken at 4.5 feet off the ground.

Tapping a tree that is too small (under 10-12 inches in diameter) can permanently damage or kill it. The 12-inch rule is a guideline for sustainable harvesting, ensuring the tree is healthy and robust enough to handle the tapping process without long-term harm.

The Goal: Income Generation

The ultimate objective of a Syrup Maker lot is to create a reliable source of income. A healthy, mature stand of maple trees can be tapped annually for decades, producing the raw sap needed to be boiled down into valuable maple syrup.

This turns a passive forest lot into an active and productive agricultural enterprise.

Understanding the Trade-offs and Realities

While the concept is powerful, implementing a "Syrup Maker" lot design requires a clear-eyed view of its challenges and commitments. It is not a passive activity.

The Investment of Time is Absolute

The most significant factor is time. If you are planting new trees, you are not planning for an income stream in five or even ten years. You are stewarding a resource that may only become fully productive for the next generation.

Active Forest Management is Required

This is not a "plant it and forget it" strategy. A productive maple stand, often called a "sugarbush," requires constant management.

This includes thinning out competing trees to provide more sunlight to the maples, monitoring for pests and diseases, and ensuring the overall health and biodiversity of the forest ecosystem.

Climate and Environmental Risks

Maple sap flow is highly dependent on specific weather patterns: freezing nights followed by thawing days. Climate change poses a significant risk, as warmer winters and less predictable spring thaws can disrupt or shorten the sap collection season, directly impacting the lot's productivity and economic viability.

Making the Right Choice for Your Goal

Applying the "Syrup Maker" principles depends entirely on your resources and long-term objectives.

- If your primary focus is long-term, sustainable income: A "Syrup Maker" lot is a viable land-use strategy, but it requires significant acreage, decades of patience, and a commitment to active forest management.

- If your primary focus is hobbyist production: You can apply these same principles on a much smaller scale by identifying and nurturing even a few mature maple trees on your property.

- If your primary focus is land conservation: This model offers a framework for managing a forest in a way that is both ecologically healthy and economically productive, providing a strong incentive for its preservation.

Ultimately, the "Syrup Maker" concept is a powerful way to reframe a forest as a living, productive system for long-term agricultural benefit.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Goal | Long-term, sustainable income from maple syrup production. |

| Core Crop | Sugar maple trees (Acer saccharum) for high-sugar sap. |

| Timeframe | 40+ years for trees to reach maturity (12-inch diameter). |

| Management | Active forestry: thinning, pest control, and ecosystem health. |

| Key Challenge | Significant time investment and vulnerability to climate change. |

Ready to Build Your Syrup Production Operation?

Managing a productive sugarbush requires reliable, high-quality equipment. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable beekeeping supplies and maple syrup production equipment needed for large-scale, professional operations.

Contact our wholesale experts today to discuss how our equipment can support your long-term Syrup Maker strategy and enhance your operational efficiency.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Durable Customizable Blister Packing Machine

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

People Also Ask

- What role do automated honey-filling machines play in trade standards? Ensure Global Export Compliance & Consistency

- What is the significance of automated honey-filling machines? Scale Your Apiary with Precision and Efficiency

- What role do automated honey filling machines play? Elevate Efficiency & Standardization in Honey Processing

- Why is a specialized honey filling machine necessary? Meet International Standards and Preserve Premium Honey Quality

- What role does honey-filling and processing machinery play in pollination? Maximize Apiary ROI & Economic Stability