In short, the consistency of an automatic filling machine is its single greatest advantage. These systems are engineered for exceptional precision, virtually eliminating the human error and variability inherent in manual or semi-automatic processes. Each container receives the exact programmed amount of product, which directly reduces waste and improves overall product quality.

The core value of an automatic filling machine isn't just speed; it's about achieving precise, repeatable control over your product. This consistency translates directly into lower costs through reduced waste and a more professional, reliable brand image.

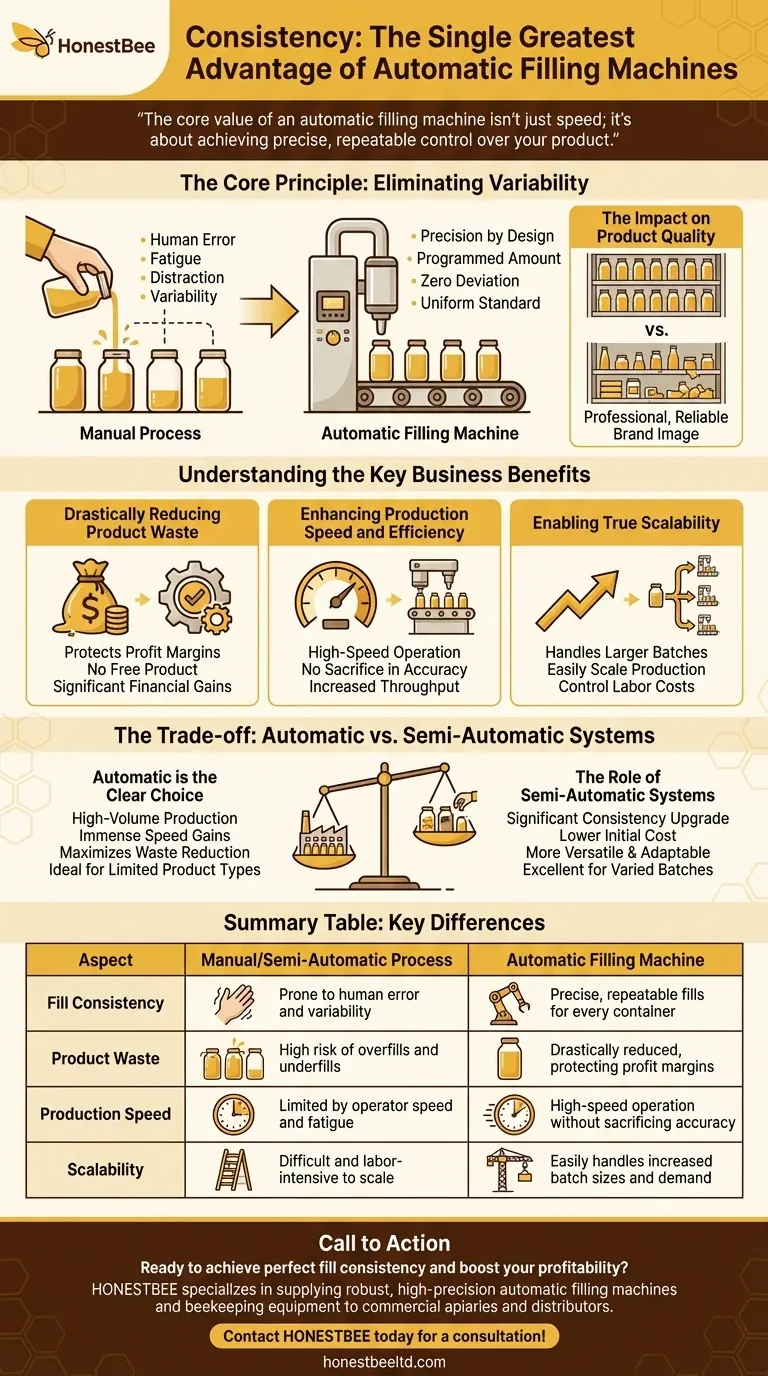

The Core Principle: Eliminating Variability

The primary function of an automatic filler is to remove variables from your packaging process. This is achieved through mechanical and digital precision that a human operator simply cannot replicate over a long production run.

Removing Human Error

Manual filling is subject to fatigue, distraction, and individual judgment. An automatic machine performs the exact same motion and dispenses the exact same volume, every single time.

This removes the possibility of over-fills (wasted product) and under-fills (unhappy customers), ensuring every unit that leaves your facility meets a uniform standard.

Precision by Design

These machines are built for one purpose: dispensing a specific quantity. Whether using a piston, pump, or auger, the mechanics are calibrated to deliver a precise volume with minimal deviation.

This engineered precision ensures that from the first container to the thousandth, the amount of product is identical.

The Impact on Product Quality

Consistency has a direct impact on customer perception. A line of perfectly and uniformly filled jars on a retail shelf looks professional and trustworthy.

Inconsistent fill levels can make a product appear low-quality or untrustworthy, even if the product itself is excellent.

Understanding the Key Business Benefits

While consistency is the technical advantage, its impact is felt across the entire business operation. The benefits go far beyond just a uniform look.

Drastically Reducing Product Waste

Even a small overfill on each container adds up to a significant financial loss over thousands of units. Automatic fillers protect your profit margins by ensuring you are not giving away free product.

Enhancing Production Speed and Efficiency

Because the process is so reliable and repeatable, automatic fillers can operate at high speeds without sacrificing accuracy. This dramatically increases your throughput compared to manual methods.

Enabling True Scalability

As your demand grows, an automatic system can easily handle larger batches. This allows your business to scale its production capacity without a proportional increase in labor costs or a decrease in quality control.

The Trade-off: Automatic vs. Semi-Automatic Systems

While fully automatic systems offer the highest level of consistency, it's important to understand where they fit in the broader landscape of filling equipment.

When Automatic is the Clear Choice

For high-volume production, especially with a limited number of product or container types, a fully automatic machine is the ideal solution. The investment is justified by the immense gains in speed, waste reduction, and labor efficiency.

The Role of Semi-Automatic Systems

Semi-automatic machines still require an operator to place containers but automate the filling action itself. They offer a significant consistency upgrade over manual methods at a lower initial cost.

These systems are often more versatile and adaptable, making them an excellent choice for businesses with a wide variety of products, container sizes, or smaller batch runs.

Making the Right Choice for Your Operation

Choosing the right equipment depends entirely on your production goals and operational scale.

- If your primary focus is maximizing throughput and minimizing waste in a high-volume operation: A fully automatic filling machine is the definitive choice for its unmatched consistency and speed.

- If your primary focus is versatility and a lower initial investment for varied product batches: A semi-automatic system provides a major boost in consistency and efficiency over manual filling while remaining adaptable.

Ultimately, investing in automated filling technology is about taking direct control over your product's quality and your operational efficiency.

Summary Table:

| Aspect | Manual/Semi-Automatic Process | Automatic Filling Machine |

|---|---|---|

| Fill Consistency | Prone to human error and variability | Precise, repeatable fills for every container |

| Product Waste | High risk of overfills and underfills | Drastically reduced, protecting profit margins |

| Production Speed | Limited by operator speed and fatigue | High-speed operation without sacrificing accuracy |

| Scalability | Difficult and labor-intensive to scale | Easily handles increased batch sizes and demand |

Ready to achieve perfect fill consistency and boost your profitability?

HONESTBEE specializes in supplying robust, high-precision automatic filling machines and beekeeping equipment to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable equipment you need to enhance product quality, reduce waste, and scale your production efficiently.

Contact HONESTBEE today for a consultation and discover the right filling solution for your high-volume operation!

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

People Also Ask

- What is the importance of professional honey filling and storage equipment for maintaining honey quality and potency?

- What is the step-by-step procedure for cleaning a honey bottling machine? A Full Guide to Food Safety

- What are the main categories of machines involved in honey packaging? Streamline Your Production for Maximum Efficiency

- How does a piston honey filling machine work? Master Precise, Hygienic Honey Packaging

- How do industrial honey-filling machines add value to Apis cerana honey? Precision Packaging for Premium Profits

- What specific issues do industrial filtration and automated filling machinery address? Ensure Honey Quality & Compliance

- What are the maintenance requirements for honey packaging machines? Prevent Downtime with a Simple Cleaning Routine

- What role do automated honey filling and packaging production lines play in honey distribution? Boost Trade Efficiency