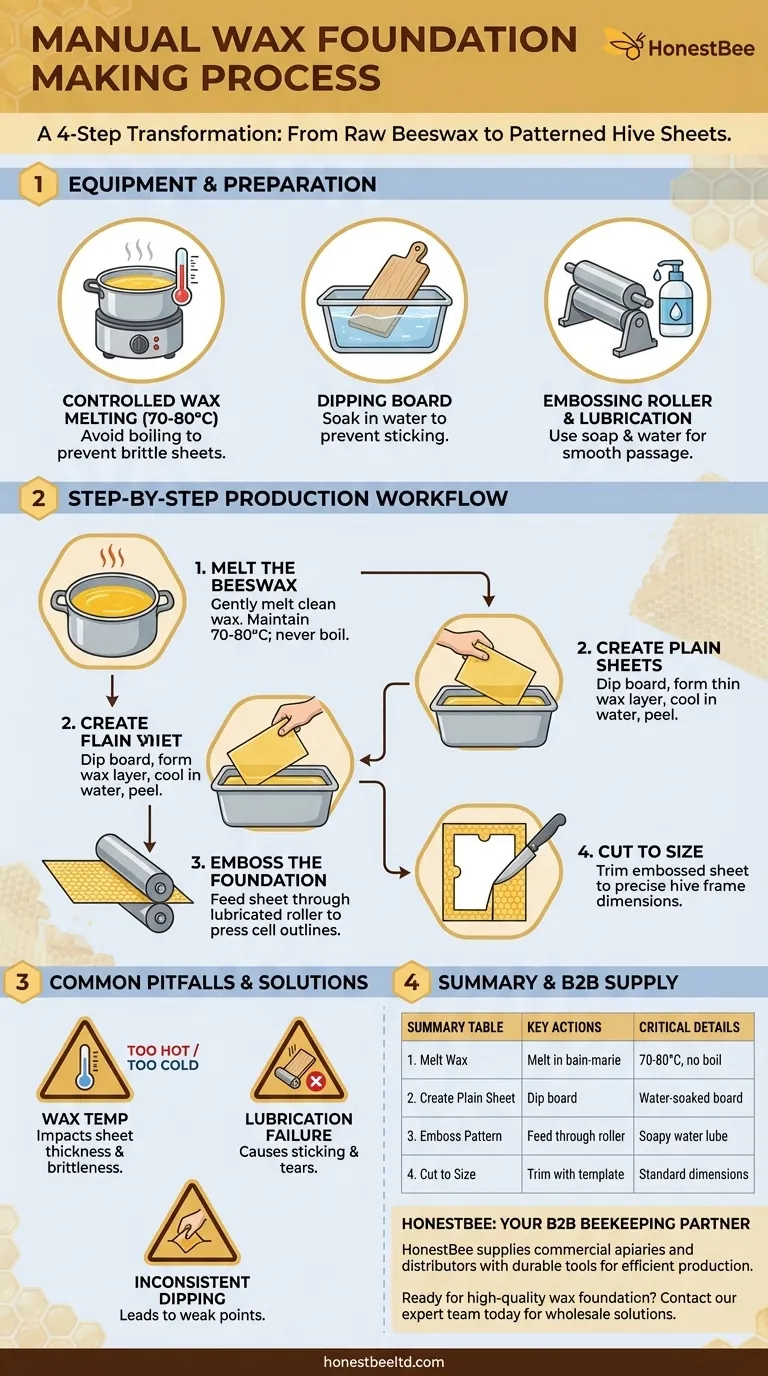

Making wax foundation by hand is a four-step process that transforms raw beeswax into patterned sheets ready for your hives. It involves carefully melting pure beeswax, creating thin, plain sheets using a dipping board, embossing these sheets with a manual roller to create the hexagonal cell pattern, and finally, cutting the foundation to the correct size for your frames.

The core principle behind making your own wax foundation is precise temperature control and mechanical imprinting. By managing the heat of the wax and properly using a lubricated embossing roller, you gain complete control over the quality and purity of a critical component in your beehive.

The Foundation of the Process: Equipment and Preparation

Before you can create the sheets, you must prepare your tools and materials correctly. Each piece of equipment serves a specific purpose, and proper preparation is the key to a smooth workflow.

Controlled Wax Melting

The process begins with melting your beeswax. This is best done in a bain-marie (a double boiler) with a thermostat-controlled element.

Maintaining a temperature between 70 and 80 degrees Celsius is critical. If the wax gets too hot or boils, its properties can be damaged, leading to brittle foundation sheets.

The Dipping Board

A simple wooden board or paddle is used to form the initial, plain sheets of wax. This board must be soaked in water for several hours before use.

The water absorbed by the wood acts as a release agent, preventing the hot wax from permanently sticking to the board and allowing you to peel the cooled sheet off easily.

The Embossing Roller

This is a heavy, purpose-built tool with the hexagonal honeycomb pattern engraved on its rollers. Its primary function is to mechanically press the cell outlines onto your plain wax sheets.

Essential Lubrication

The rollers must be lubricated to ensure the wax sheets pass through smoothly without sticking or tearing. A simple solution of soap and water works effectively as a release agent for the metal rollers.

The Step-by-Step Production Workflow

Once your equipment is prepared, you can begin the production process. This is a hands-on procedure that rewards a methodical and patient approach.

Step 1: Melt the Beeswax

Gently melt your clean beeswax in the top of the bain-marie. Monitor the temperature closely to ensure it stays within the 70-80°C range and never boils.

Step 2: Create the Plain Sheets

Dip the water-soaked wooden board into the melted wax. Submerge it for a moment and then pull it out, allowing a thin, even layer of wax to coat the surface. Dip it briefly in cool water to set the wax, then gently peel the plain sheet from the board.

Step 3: Emboss the Foundation

Lightly lubricate the embossing rollers with the soapy water solution. Carefully feed a plain wax sheet into the roller. The weight of the machine will press the hexagonal cell pattern firmly into the wax.

Step 4: Cut to Size

Using a frame template and a sharp knife or pizza cutter, trim the embossed foundation sheet to the precise dimensions required for your hive frames.

Understanding the Common Pitfalls

While the process is straightforward, a few key variables can dramatically impact your results. Understanding these helps you avoid common frustrations.

Wax Temperature is Critical

If your wax is too hot, the sheets you dip will be excessively thin and brittle. If it's too cool, the sheets will be too thick and may not take the impression from the roller cleanly.

The Importance of Lubrication

Forgetting to lubricate the dipping board (by soaking it in water) or the embossing roller (with soap suds) will cause major problems. Wax will stick tenaciously to these surfaces, ruining your sheets and requiring a difficult cleanup.

Sheet Thickness Consistency

Achieving consistent thickness comes from a smooth, even dipping motion. Rushing this step can create sheets with thick and thin spots, which can lead to weak points in the final foundation.

Making the Right Choice for Your Goal

By controlling this process, you can tailor the outcome to your specific beekeeping objectives.

- If your primary focus is quality and purity: Emphasize using clean, filtered beeswax and maintaining precise temperature control throughout the entire process.

- If your primary focus is self-sufficiency: Master a consistent workflow that allows you to efficiently recycle wax from your own cappings and old comb into new foundation.

This process places one of the most fundamental aspects of beekeeping directly in your hands.

Summary Table:

| Step | Key Action | Critical Detail |

|---|---|---|

| 1. Melt Wax | Gently melt in a bain-marie | Maintain 70-80°C; never boil |

| 2. Create Plain Sheet | Dip water-soaked board into wax | Peel cooled sheet for embossing |

| 3. Emboss Pattern | Feed sheet through lubricated roller | Use soapy water to prevent sticking |

| 4. Cut to Size | Trim sheet with a sharp tool | Fit standard hive frame dimensions |

Ready to produce your own high-quality wax foundation? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, reliable tools needed for efficient honey production. From manual rollers to full-scale melting equipment, our wholesale-focused operations ensure you get the right gear for your operation. Contact our expert team today to discuss your beekeeping supply needs and streamline your foundation production.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- Manual Spur Wheel Wire Embedder for Foundation

- Food Grade Plastic bee Foundation for Bee Frames

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How does the beeswax flatting and embossing machine prepare the wax for processing? Achieve Perfectly Uniform Wax Sheets

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction

- What equipment is needed to make beeswax foundation? A Guide to DIY Wax Sheet Production

- What precautions should be taken during the milling of wax sheets? A Guide to Producing Flawless Foundation

- What is the primary function of the manual honeycomb embossing machine? Gain Control Over Your Hive's Foundation