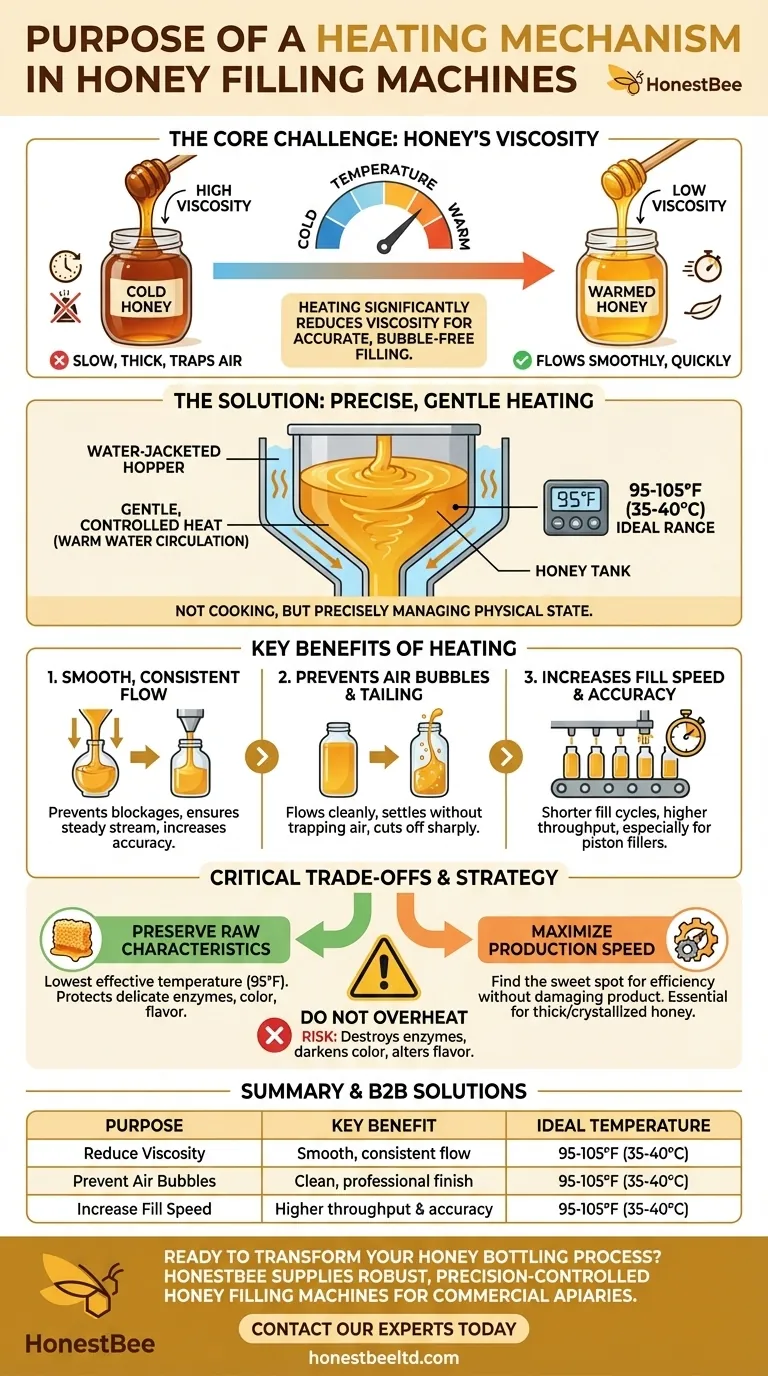

In short, a heating mechanism is used in honey filling machines to gently warm the honey, which significantly reduces its thickness or viscosity. This allows the honey to flow smoothly and quickly through the machine, ensuring each container is filled accurately and without trapping air bubbles, leading to a more efficient process and a more professional final product.

The purpose of heating is not to cook the honey, but to precisely manage its physical state. It is a critical control measure for transforming a thick, slow-moving liquid into a cooperative fluid, enabling high-speed, high-quality bottling.

The Core Challenge: Understanding Honey's Viscosity

To understand why heating is necessary, you must first understand the primary physical property that makes honey bottling a challenge: viscosity.

What is Viscosity?

Viscosity is a measure of a fluid's resistance to flow. A fluid with high viscosity, like cold honey, is "thick" and flows slowly. A fluid with low viscosity, like water, is "thin" and flows easily.

The Critical Role of Temperature

Honey's viscosity is highly dependent on its temperature. As honey is gently warmed, its viscosity drops dramatically.

This inverse relationship is the entire reason heating systems are integrated into filling machines. A small increase in temperature can make a massive difference in how the honey behaves.

How Heating Solves the Filling Problem

By reducing honey's viscosity, a heating mechanism directly solves the most common bottling frustrations and inefficiencies.

Ensuring a Smooth, Consistent Flow

Warmed, less-viscous honey moves easily through the machine's pumps, tubes, and nozzles. This prevents blockages and ensures a steady stream, which is fundamental for any automated or semi-automated process.

Preventing Air Bubbles and "Tailing"

Cold, thick honey tends to trap air as it's forced into a container, resulting in unsightly bubbles. It also creates a long, sticky string or "tail" when the fill is complete, creating a mess and wasting product. Warmed honey flows cleanly, settles without trapping air, and cuts off sharply from the nozzle.

Increasing Fill Speed and Accuracy

A machine's efficiency is measured in containers filled per hour. Because warmed honey flows faster, the fill cycle for each container is shorter, dramatically increasing overall throughput. This is especially true for piston fillers, which rely on dispensing a precise volume. Thick honey can strain the mechanism and lead to inaccurate fills, a problem that heating eliminates.

Understanding the Trade-offs and Risks

While essential, heating honey is a delicate process that requires precise control. The goal is to improve flow characteristics without damaging the product.

The Risk of Overheating

Honey is a sensitive natural product. Excessive heat will destroy its delicate enzymes, darken its color, and alter its flavor profile. Overheating can turn premium raw honey into a lower-grade product.

The Importance of Gentle, Controlled Heat

Professional-grade machines do not apply direct, harsh heat. They typically use a water-jacketed hopper, where warm water circulates around the honey tank to provide gentle, even heat.

A reliable thermostat is non-negotiable. The goal is to warm the honey to the lowest effective temperature (often just 95-105°F or 35-40°C) that achieves the desired viscosity for a smooth filling process.

Making the Right Choice for Your Operation

Use the heating mechanism as a strategic tool to meet your specific production goals.

- If your primary focus is preserving raw honey characteristics: Use the lowest possible temperature setting that still allows for a clean, efficient fill and invest in a machine with a high-quality water jacket and thermostat.

- If your primary focus is production speed and efficiency: A heating system is essential to maximize your output, but monitor the temperature carefully to find the sweet spot between speed and maintaining product quality.

- If you are working with crystallized or very thick honey (e.g., Manuka): A reliable heating element is not optional; it is a fundamental requirement for a viable bottling process.

Properly managed, a heating system transforms honey bottling from a sticky challenge into a precise, efficient, and quality-driven process.

Summary Table:

| Purpose of Heating | Key Benefit | Ideal Temperature Range |

|---|---|---|

| Reduce Viscosity | Smooth, consistent flow | 95-105°F (35-40°C) |

| Prevent Air Bubbles | Clean, professional finish | 95-105°F (35-40°C) |

| Increase Fill Speed | Higher throughput & accuracy | 95-105°F (35-40°C) |

Ready to transform your honey bottling process?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with robust, precision-controlled honey filling machines. Our wholesale-focused operations ensure you get the durable equipment you need to maximize efficiency while protecting the delicate quality of your honey.

Contact our experts today to find the perfect filling solution for your scale and quality requirements.

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What types of honey filling machines are available? Find the Perfect System for Your Apiary

- How does the temperature control system in honey filling production lines affect quality? Master Precision Processing

- How does a Semi-automated Machine differ from an Automatic Viscous Liquid Filling Machine? Key Differences Explained

- What functions do automated honey processing and filling machines provide? Secure High-Value Monofloral Honey Quality

- How do specialized machines for packing honey enhance the commercial value of honey products? Scale Your Brand Today

- How should cost-effectiveness be evaluated when choosing a honey packaging machine? Maximize ROI and Efficiency

- What is a manual honey filler and where is it used? The Essential Guide for Small-Scale Honey Bottling

- How does an overflow honey bottle filling machine work? Achieve Perfect Shelf Appeal for Your Brand