In honey processing, uncapping is the essential first step to releasing honey from the comb. It is the process of manually or mechanically removing the thin wax "caps" that bees build to seal each cell of the honeycomb. By breaking this wax seal, beekeepers expose the liquid honey, making it possible to extract it from the comb.

Uncapping is not merely about removing wax; it is the critical gateway to efficient honey extraction. Without properly uncapping the comb, even the most powerful extractor is rendered useless, as the honey remains trapped within its sealed wax cells.

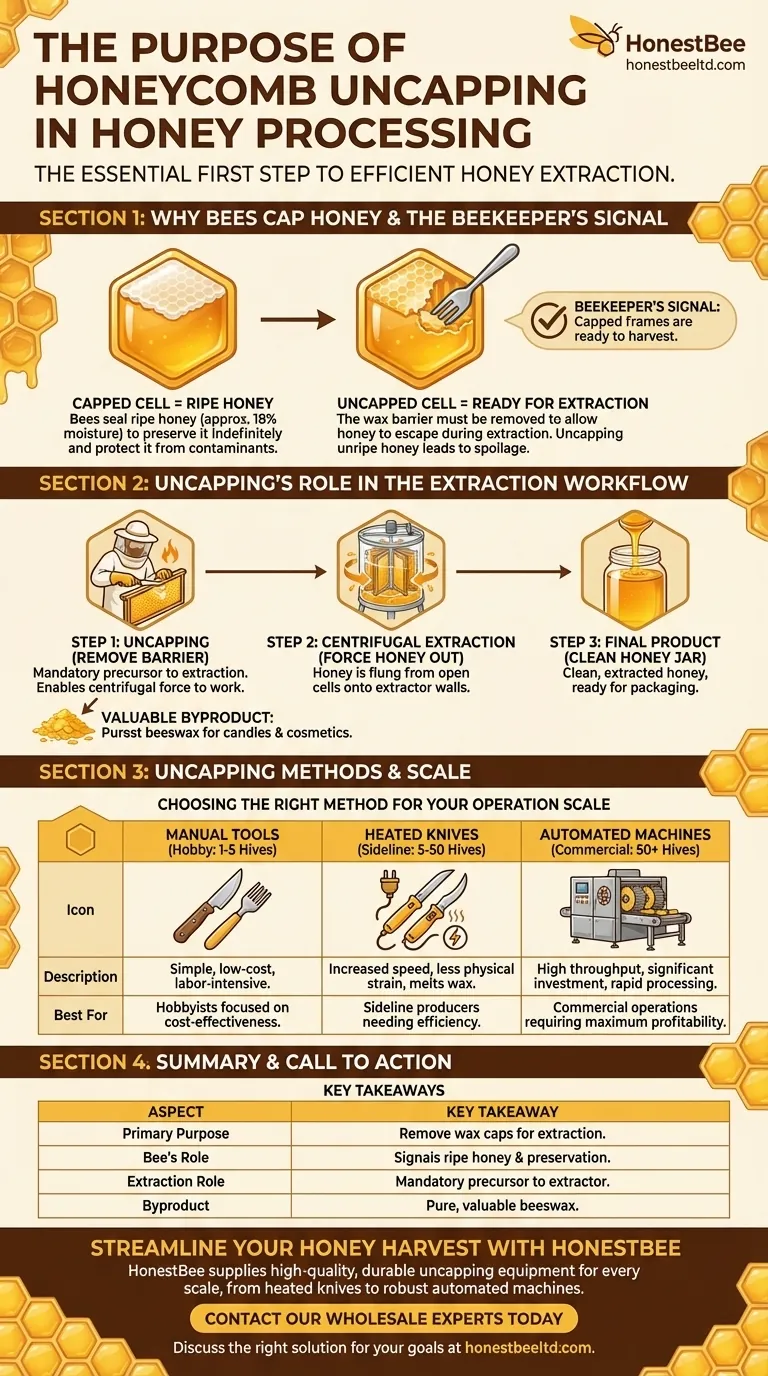

Why Bees Cap Honey in the First Place

To understand why uncapping is necessary, we must first understand why bees cap their honey. This is not a random act but a crucial part of their own food preservation process.

A Sign of "Ripe" Honey

Bees place nectar into honeycomb cells and then fan it with their wings to evaporate moisture. When the water content drops to around 18%, the honey is considered "ripe" and will not ferment.

At this point, the bees seal the cell with a fresh wax cap. This airtight seal protects the honey from moisture and contaminants, preserving it indefinitely for their winter food supply.

The Beekeeper's Signal

For a beekeeper, a frame of capped honey is the definitive signal that the honey is ready for harvest. Extracting uncapped or "unripe" honey with high moisture content will lead to fermentation and spoilage.

Uncapping's Role in the Extraction Workflow

Honey processing is a sequence of steps designed to move honey from the hive to the jar cleanly and efficiently. Uncapping is the mandatory starting point for extraction.

The Precursor to Extraction

The wax cap, while excellent for preservation, creates a barrier. Before honeycombs are placed into an extractor, this barrier must be removed from both sides of the frame.

Enabling Centrifugal Force

A honey extractor works by spinning frames at high speed. This centrifugal force flings the liquid honey out of the cells and onto the walls of the extractor drum, where it drains to the bottom.

If the cells remain capped, the honey has nowhere to go. Uncapping provides the exit path, allowing the extractor to do its job effectively.

The Source of a Valuable Byproduct

The wax cappings removed during this process are not waste. They are considered the purest beeswax in the hive and are highly prized. These cappings can be melted and filtered to create clean beeswax for candles, cosmetics, or new foundation for beehive frames.

Understanding the Trade-offs and Methods

The method used for uncapping depends entirely on the scale of the operation, from a single hobbyist hive to a large commercial facility. Each method has distinct implications.

Manual Tools: Knives and Forks

For small-scale beekeepers, the most common tools are uncapping knives or forks (also called scratchers). A knife is used to slice off the top layer of cappings in a single sheet.

An uncapping fork is used to scratch open the caps, which is useful for frames with uneven or low-lying capped areas that a knife would miss. These methods are simple and low-cost but labor-intensive.

Electric and Steam Knives

For sideline beekeepers, an electric or steam-heated knife is a significant upgrade. The heat melts the wax as it cuts, allowing the knife to glide through the cappings with minimal effort. This greatly increases speed and reduces physical strain.

The primary trade-off is the slight heating of the honey at the surface of the comb. While generally minimal, it is a factor for purists who insist on a completely "raw" process.

Automated Uncapping Machines

Commercial operations handling hundreds or thousands of frames rely on automated uncapping machines. These devices use heated blades, flails, or rotating brushes to uncap entire frames in seconds.

While incredibly efficient, these machines represent a significant capital investment and require careful calibration to avoid damaging the wooden frames or the underlying honeycomb structure.

Making the Right Choice for Your Goal

Your uncapping method should directly align with the scale of your beekeeping operation and your efficiency goals.

- If your primary focus is hobby beekeeping (1-5 hives): A simple cold uncapping knife and a scratcher fork are perfectly sufficient and the most cost-effective choice.

- If your primary focus is sideline production (5-50 hives): Investing in an electric or steam-heated knife will dramatically improve your speed and make processing days far less strenuous.

- If your primary focus is commercial operation (50+ hives): An automated uncapping machine is an essential piece of equipment for achieving the throughput needed to be profitable.

Ultimately, proper uncapping is the foundation upon which an efficient and successful honey harvest is built.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Purpose | To remove wax caps, allowing honey to be extracted from the comb. |

| Bee's Role | Capping signals honey is ripe (low moisture) and preserves it. |

| Extraction Role | Mandatory precursor to using a centrifugal extractor. |

| Byproduct | Cappings are a source of pure, valuable beeswax. |

| Method Choice | Depends on operation scale: manual knives, heated knives, or automated machines. |

Ready to Streamline Your Honey Harvest?

For commercial apiaries and beekeeping equipment distributors, efficient uncapping is the foundation of a profitable operation. HONESTBEE supplies the high-quality, durable uncapping equipment you need to maximize throughput and honey quality, from heated knives for sideline producers to robust automated machines for large-scale facilities.

Contact our wholesale experts today to discuss the right uncapping solution for your scale and goals.

Visual Guide

Related Products

- Professional Honey Uncapping Roller for Efficient Harvesting

- Professional Honey Uncapping Fork Tool with Customizable Tine Options

- Stainless Steel Dual Blade Uncapping Plane

- Professional Bent Tine Honey Uncapping Fork with Ergonomic Grip

- Professional Stainless Steel Double-Sided Honey Uncapping Knife

People Also Ask

- What is uncapping honey? Unlock the Key Step to Efficient Honey Harvesting

- What is an electric heating honey scraper and how does it work? Streamline Your Honey Harvest

- What is the best method for uncapping honey? A Guide to Speed vs. Comb Preservation

- What are two methods for crushing comb to extract liquid honey from a top-bar hive? Master Extraction Techniques.

- What is an uncapping roller? The Essential Tool for Bee-Centric Beekeepers