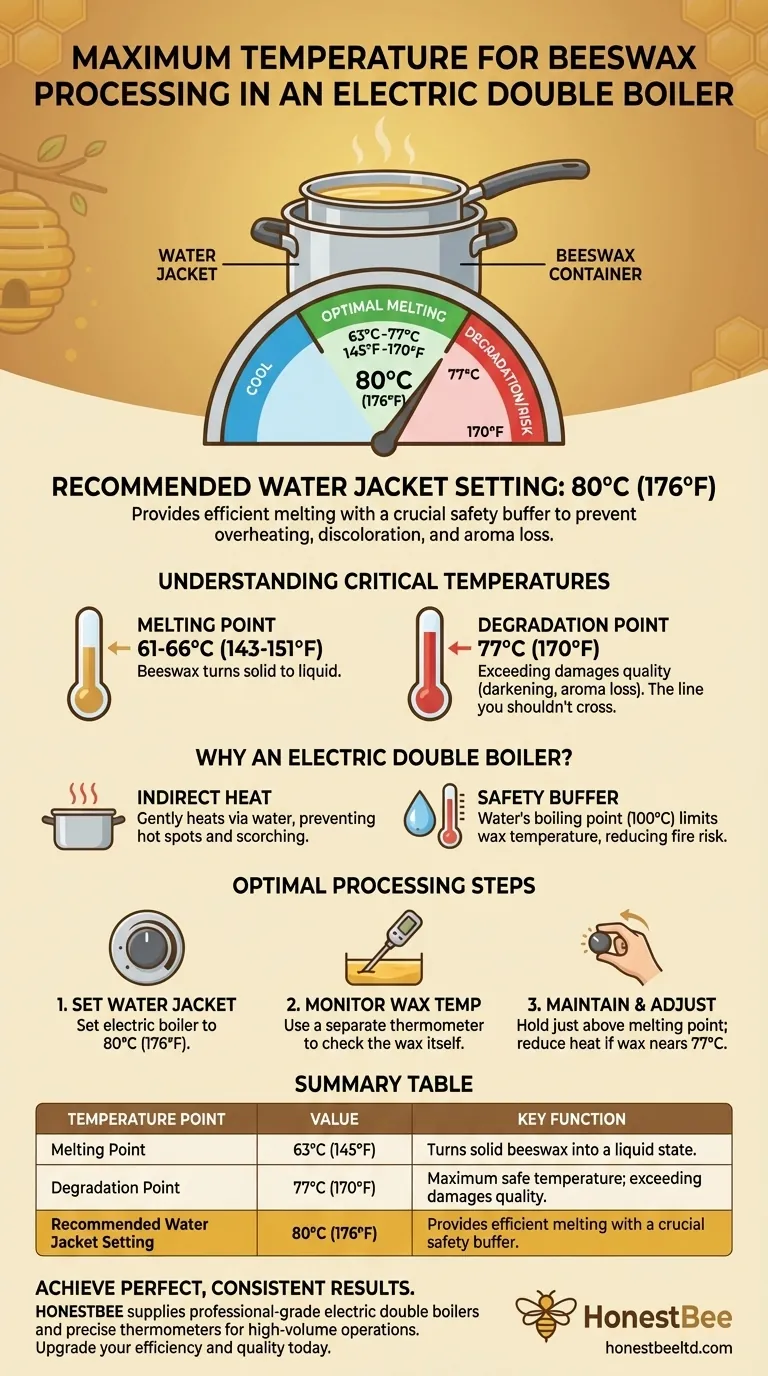

For your electric double boiler, the recommended maximum temperature setting for the water jacket is 80°C (176°F). This setting provides enough heat to melt the beeswax efficiently while creating a crucial safety buffer to prevent the wax itself from overheating, which can cause discoloration and a loss of its natural aroma.

The core challenge in processing beeswax is not just melting it, but doing so gently. You must raise the wax above its melting point of approximately 63°C (145°F) without letting it exceed its degradation point of 77°C (170°F). The double boiler is the essential tool for achieving this precise control.

Understanding the Critical Temperatures of Beeswax

To handle beeswax correctly, you must understand two key temperature thresholds. These numbers dictate the entire process.

The Melting Point: Turning Solid to Liquid

Beeswax begins to melt when it reaches a temperature between 61-66°C (143-151°F). Your goal is to get the entire volume of wax just above this range so it becomes a workable liquid.

The Degradation Point: The Line You Shouldn't Cross

If beeswax is heated beyond 77°C (170°F), it begins to degrade. The natural golden color can darken or "scorch," and the delicate, honey-like aroma will be lost. Exceeding this temperature damages the very qualities that make beeswax valuable.

Why a Double Boiler is Non-Negotiable

Using a double boiler, especially an electric one with temperature control, is the standard for a reason. It is fundamentally a tool for managing risk and ensuring quality.

Indirect Heat for Quality Control

A double boiler melts the wax with indirect heat. The unit heats the water, and the water, in turn, gently heats the container holding the wax. This prevents hot spots that can scorch the wax, which is a common problem with direct heat methods.

A Built-in Safety Buffer

The water in the lower pan acts as a temperature regulator. Because water boils at 100°C (212°F), it creates a natural temperature ceiling, making it much harder to dangerously overheat the wax to its flashpoint, which poses a significant fire risk.

The Optimal Melting Process

Setting the dial is only one part of the process. True quality control comes from monitoring the wax itself.

Setting the Water Jacket

Begin by setting your electric double boiler's water temperature to 80°C (176°F). This provides a gentle, consistent heat source that is warm enough to melt the wax but low enough to give you a margin of safety.

Monitoring the Wax Temperature

The water temperature is not the same as the wax temperature. Use a separate, accurate thermometer (like a digital probe or candy thermometer) to monitor the temperature of the wax itself. This is the most important measurement.

What to Look For

Once the wax is fully melted, your goal is to hold it just above its melting point. If you see the temperature climbing toward 77°C (170°F), you can turn down or temporarily shut off the heat. An electric unit will automatically cycle its heating element to maintain the set water temperature.

Understanding the Trade-offs and Risks

While a double boiler is safe, awareness of potential issues is key to a flawless process.

The Risk of Overheating

The most common mistake is focusing only on the boiler's setting and not the wax's actual temperature. Setting the boiler too high (e.g., to a full boil at 100°C) significantly reduces your margin for error and can quickly overheat the wax past its 77°C (170°F) degradation point.

Preventing Water Contamination

Ensure the inner bowl or pan rests securely on the lip of the outer pot. You want to prevent any steam or water droplets from getting into your beeswax, as this can cause sputtering when pouring and affect the final quality of your candles or cosmetics.

The Danger of the Flashpoint

Never leave melting beeswax unattended. While a double boiler minimizes the risk, it's important to know that beeswax has a flashpoint (the temperature at which its vapors can ignite) of around 204°C (400°F). Never attempt to melt beeswax with direct heat, such as in a pan directly on a stove.

Making the Right Choice for Your Goal

Use these guidelines to tailor the process to your specific outcome.

- If your primary focus is preserving the natural color and aroma: Keep your wax temperature consistently below 77°C (170°F) by carefully monitoring it with a separate thermometer.

- If your primary focus is safety and efficiency: Set your electric double boiler's water jacket to 80°C (176°F) and never leave the unit unattended while it is operating.

- If you are filtering the wax: Allow the wax to melt completely and hold it at a stable temperature around 70°C (158°F) to ensure it stays liquid as you pour it through your filters.

By understanding the properties of the wax and using your equipment correctly, you can achieve perfect, repeatable results every time.

Summary Table:

| Temperature Point | Value | Key Function |

|---|---|---|

| Melting Point | 63°C (145°F) | Turns solid beeswax into a liquid state. |

| Degradation Point | 77°C (170°F) | Maximum safe temperature; exceeding it damages wax quality. |

| Recommended Water Jacket Setting | 80°C (176°F) | Provides efficient melting with a crucial safety buffer. |

Achieve Perfect, Consistent Beeswax Processing Every Time

As a commercial apiary or beekeeping equipment distributor, your reputation depends on the quality of your products. Properly processed beeswax is fundamental. HONESTBEE supplies the professional-grade electric double boilers and precise thermometers you need to master this critical step.

We understand the demands of high-volume operations. Our wholesale-focused approach provides you with reliable, durable equipment that ensures safety and preserves the valuable qualities of your beeswax.

Ready to upgrade your processing efficiency and product quality?

Contact HONESTBEE today to discuss your commercial beekeeping supply needs and discover how our equipment can support your business goals.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- What factors should be considered when choosing a wax melter? Optimize Your Beekeeping Efficiency

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards