At its core, filtration is the critical processing step that removes physical impurities from raw honey, such as wax particles, bee parts, and other debris collected from the hive. This purification process is essential for creating the clean, clear, and stable liquid honey that is expected in most commercial markets.

The fundamental purpose of filtration extends beyond simple cleaning. It is a strategic process designed to enhance the honey's visual appeal, extend its liquid shelf life, and ensure a consistent, high-quality product ready for bottling and sale.

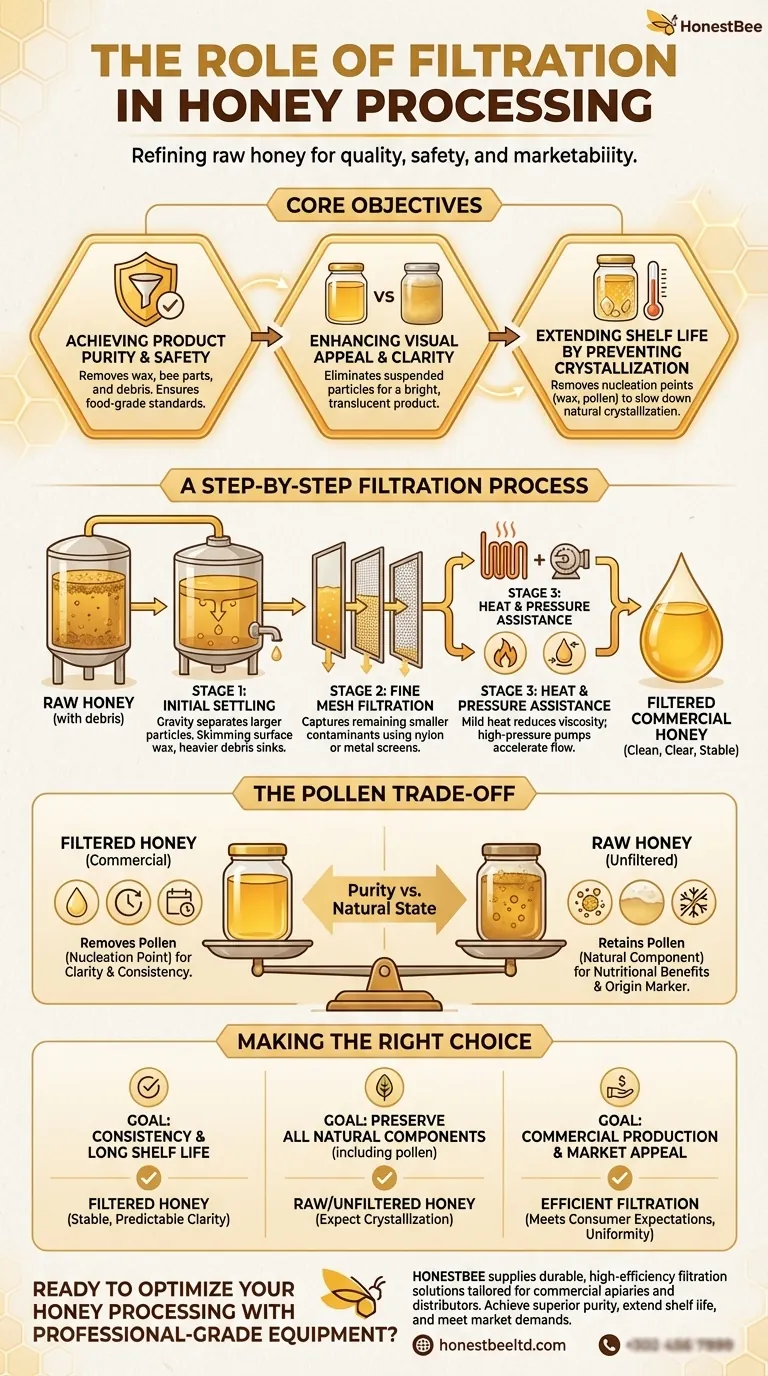

The Core Objectives of Honey Filtration

To understand its importance, we must look at the specific goals filtration achieves. It’s not about altering the honey itself, but refining it for safety, stability, and marketability.

Achieving Product Purity and Safety

The most immediate goal of filtration is to remove all visible, non-honey contaminants. This includes bits of beeswax, wood splinters from the hive frames, and other small debris.

Removing these particles is a fundamental step in quality control, ensuring the final product is pure, safe, and meets food-grade sanitation standards.

Enhancing Visual Appeal and Clarity

Consumers associate high-quality honey with a bright, clear appearance. Filtration removes fine, suspended particles that can make the honey look cloudy or murky.

This process results in a visually appealing, translucent product that is far more attractive on a retail shelf, directly impacting its marketability and consumer trust.

Extending Shelf Life by Preventing Crystallization

Many of the small particles removed during filtration—especially tiny wax and pollen grains—can act as nucleation points. These are physical "seeds" around which sugar crystals begin to form.

By filtering these particles out, the process significantly slows down the natural crystallization of honey, keeping it in a liquid state for much longer and extending its shelf life.

A Step-by-Step Look at the Filtration Process

Commercial filtration is a multi-stage process, often assisted by technology to ensure efficiency and consistency.

Initial Settling: The First Pass

Before active filtration, honey is often held in a settling tank. Here, gravity does the initial work.

Lighter particles, like larger pieces of wax, rise to the surface and are skimmed off, while heavier debris may sink. This pre-cleans the honey and reduces the load on the fine filters.

Fine Mesh Filtration: The Primary Cleaning Stage

After settling, the honey is passed through a series of fine mesh filters, typically made of nylon or metal.

These screens are designed to capture the remaining smaller particles, ensuring only pure honey passes through to the next stage.

The Role of Heat and Pressure

Honey is highly viscous, meaning it flows slowly. To aid the process, processors often apply mild heat. This reduces the honey's viscosity, allowing it to pass through the fine filters more easily without degrading its natural qualities.

In many systems, high-pressure pumps are also used to accelerate the flow of honey through the filters, shortening processing time and boosting overall efficiency.

Understanding the Trade-offs

While filtration is essential for the commercial honey industry, it's important to recognize what is being changed. The key point of debate centers on one specific particle.

The Removal of Pollen

Very fine filtration systems can remove most of the pollen grains naturally present in honey. For commercial producers, this is a desirable outcome, as pollen also acts as a nucleation point for crystallization.

However, for consumers seeking "raw" honey, pollen is a valued component. It is often believed to contain unique nutritional benefits and serves as a definitive marker of the honey's floral and geographic origin.

Purity vs. Natural State

The decision to filter, and to what degree, represents a trade-off between different product goals.

Commercial honey prioritizes clarity, consistency, and a long liquid shelf life. Unfiltered or "raw" honey prioritizes retaining all of its natural components, accepting a cloudier appearance and faster crystallization as a result.

Making the Right Choice for Your Goal

Ultimately, the type of honey you choose depends on your priorities.

- If your primary focus is consistency and a long liquid shelf life: Standard filtered honey is the definitive choice for its stability and predictable clarity.

- If your primary focus is preserving all natural components, including pollen: Seek out specifically labeled "raw" or "unfiltered" honey, and expect it to crystallize over time.

- If your primary focus is commercial production and market appeal: An efficient filtration system is non-negotiable for meeting consumer expectations and ensuring product uniformity.

Understanding the function of filtration empowers you to choose a product that aligns perfectly with your definition of quality.

Summary Table:

| Key Aspect | Role of Filtration |

|---|---|

| Purity & Safety | Removes wax, bee parts, and debris to meet food-grade standards. |

| Visual Appeal | Eliminates cloudiness for a clear, market-ready product. |

| Shelf Life | Reduces nucleation points to delay crystallization. |

| Process Efficiency | Uses heat and pressure for faster, consistent results. |

Ready to optimize your honey processing with professional-grade filtration equipment?

At HONESTBEE, we supply durable, high-efficiency beekeeping supplies and equipment tailored for commercial apiaries and distributors. Our filtration solutions help you achieve superior product purity, extend shelf life, and meet market demands with confidence.

Contact us today to discuss your wholesale needs and discover how our expertise can enhance your operation's productivity and profitability.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Stainless Steel Honey Filter with Support Handle

People Also Ask

- What technical challenges does honey filtration equipment address? Optimize Purity and Quality in Post-Processing

- How do high-precision processing and filtration systems assist in meeting organic honey quality compliance?

- How is honey filtered after extraction? Choose the Right Method for Raw or Commercial Honey

- What is the purpose of using a standard grading sieve before filling propolis powder? Optimize Capsule Quality

- What are the benefits of using honey distribution centers? Scale Your Trade with Industrial Storage and Filtration

- How do honey refining and filtering machines enhance value? Elevate Purity & Market Price in Post-Processing

- How do fermentation tanks and filtration systems support mead production? Elevate Honey into Premium Value-Added Goods

- Why is the use of high-density filter cloth necessary during the processing of stingless bee honey? Ensure Pure Quality