To calibrate a honey refractometer, you should use the specific reference solution that typically comes with the device. This liquid is labeled with a known moisture content value, providing a precise baseline. If a reference solution is not available, pure olive oil can be used as a reliable alternative to calibrate the refractometer to the 27% water content mark.

While specific calibration liquids provide the direct answer, achieving a truly accurate honey reading is a systematic process. Calibration is the critical first step, but temperature, sample application, and cleaning are equally vital for ensuring the measurement is reliable.

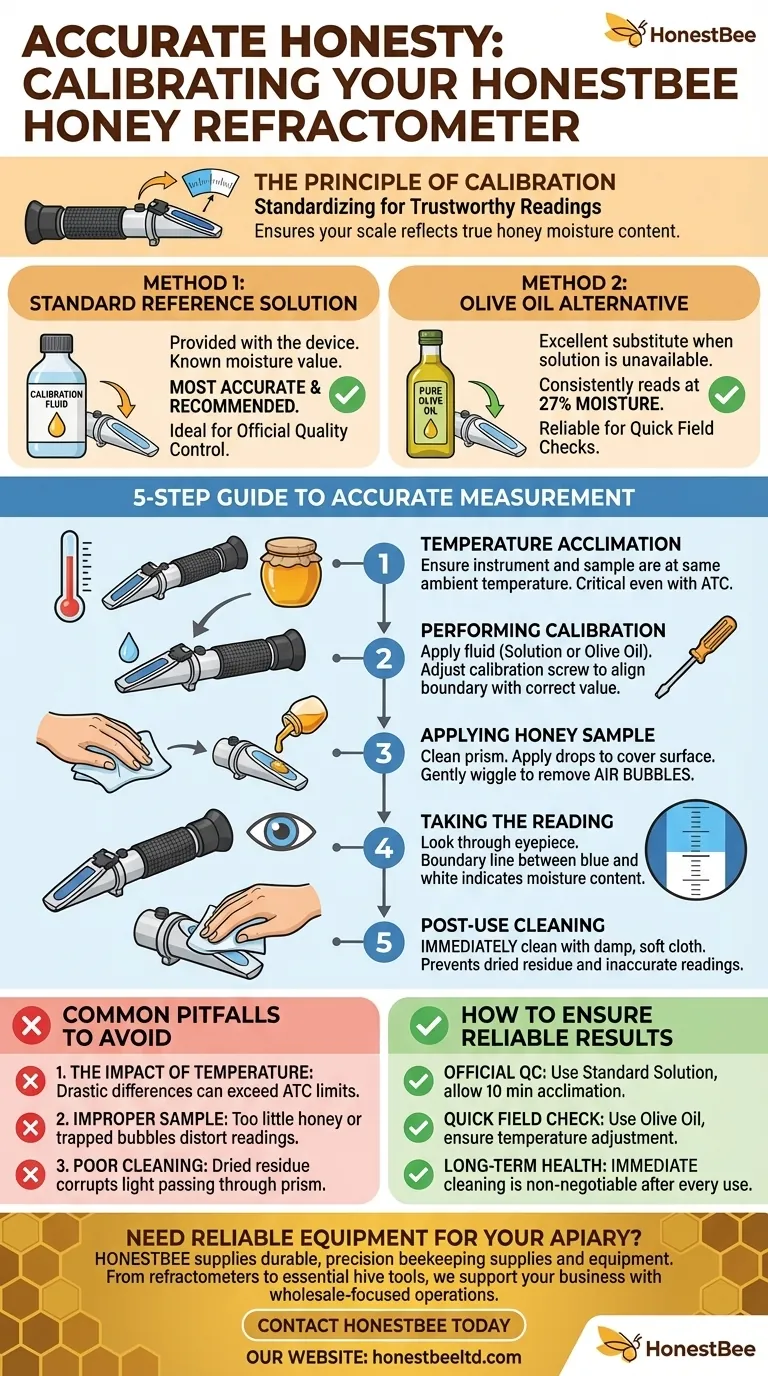

The Principle of Calibration

Calibration is the process of standardizing an instrument against a known, fixed reference point. For a honey refractometer, this ensures that the scale you are reading accurately reflects the true moisture content of your honey.

Using a Standard Reference Solution

Most new refractometers are packaged with a small vial of calibration fluid. This liquid has a predetermined value, which you will use to set your instrument's baseline. This is the most accurate and recommended method.

Using Olive Oil as an Alternative

In the absence of a dedicated reference solution, pure olive oil serves as an excellent substitute. Olive oil consistently reads at 27% on the water/moisture scale. Place a drop on the prism, close the cover, and adjust the calibration screw until the reading is precisely at the 27% line.

A Step-by-Step Guide to Accurate Measurement

Achieving a trustworthy measurement involves more than just the calibration step. Each part of the process builds on the last to ensure the final reading is correct.

Step 1: Temperature Acclimation

Ensure both the refractometer and the honey sample are at the same ambient temperature. A significant temperature difference between the instrument and the sample is a primary source of inaccurate readings, even with devices that have Automatic Temperature Compensation (ATC).

Step 2: Performing the Calibration

Place a few drops of your chosen calibration fluid (reference solution or olive oil) onto the prism glass. Close the daylight plate gently and check the reading. Turn the calibration screw until the boundary line (the separation of the blue and white fields) aligns perfectly with the correct value on the scale.

Step 3: Applying the Honey Sample

After wiping the prism clean with a soft, lint-free cloth, apply a drop or two of honey. Ensure the honey completely covers the prism surface. Close the daylight plate and gently wiggle it to remove any trapped air bubbles, which can distort the reading.

Step 4: Taking the Reading

Hold the refractometer up to a light source and look through the eyepiece. The point where the boundary line between the blue and white areas intersects the scale indicates the moisture content of your honey. Adjust the eyepiece to bring the scale into sharp focus if needed.

Step 5: Post-Use Cleaning

Immediately after you are finished, clean the honey off the prism and daylight plate. Use a damp, lint-free cloth. Failure to clean the instrument can lead to dried residue that will corrupt all future measurements.

Common Pitfalls to Avoid

Even with a calibrated device, simple mistakes can compromise your results. Being aware of these common issues is key to maintaining accuracy.

The Impact of Temperature

Automatic Temperature Compensation (ATC) is a crucial feature that corrects for ambient temperature variations, but it has limits. It works best when the instrument and sample have had time to equalize to the same temperature. Drastic differences can still cause errors.

The Risk of an Improper Sample

Using too little honey will not cover the prism, leading to an undefined boundary line. Trapped air bubbles create visual distortions that make it difficult to identify the precise reading.

The Consequence of Poor Cleaning

Dried honey residue or smudges on the prism will alter how light passes through it. This directly interferes with the refractometer's principle of operation, making subsequent readings inaccurate and unreliable. Store the clean, dry instrument in its case to prevent damage.

How to Ensure Reliable Results

Your goal dictates how you should approach the process. Follow these guidelines to get the data you need.

- If your primary focus is official quality control: Always use the manufacturer-provided reference solution for calibration and allow at least 10 minutes for temperature acclimation.

- If your primary focus is a quick field check: Use olive oil for a reliable calibration and ensure the instrument has been out of its case for a few minutes to adjust to the ambient temperature.

- If your primary focus is long-term instrument health: Make immediate and thorough cleaning with a damp, soft cloth a non-negotiable habit after every single use.

Ultimately, consistent accuracy is achieved by treating measurement as a disciplined, repeatable process from start to finish.

Summary Table:

| Calibration Method | Key Information | Recommended Use |

|---|---|---|

| Standard Reference Solution | Provided with the device; has a known moisture value. | Most accurate; ideal for official quality control. |

| Olive Oil (Alternative) | Consistently reads at 27% on the moisture scale. | Reliable for quick field checks when a reference solution is unavailable. |

Need Reliable Equipment for Your Apiary?

Accurate measurement is fundamental to producing high-quality honey. For commercial apiaries and beekeeping equipment distributors, having dependable, easy-to-use tools is non-negotiable.

HONESTBEE supplies the durable, precision beekeeping supplies and equipment you need to operate efficiently and profitably. From refractometers to essential hive tools, we support your business with wholesale-focused operations.

Contact HONESTBEE today to discuss your equipment needs and discover how we can help streamline your operations and protect your product quality.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- Electric Double Wall Honey Filtering Machine Purifier Equipment for Honey Processing Plant

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- Why is a portable digital refractometer essential for measuring moisture content in honey? Ensure Ripeness & Quality

- Why is it important to measure the moisture content of honey before harvesting? Prevent Fermentation & Ensure Quality

- What substances can be used to calibrate a honey refractometer? Essential Solutions for Accurate Moisture Readings

- Why is a portable honey refractometer essential for mono-floral honey? Master Moisture Control & Quality.

- What is the primary mechanism of using a spectrophotometer for honey color assessment? Master Objective Grading

- Why are benchtop refractometers critical for honey? Master Moisture Control and Ensure Long-Term Quality

- What is the operating principle of a precision refractometer? Mastering Honey Moisture Detection Accuracy

- How is a refractometer used to evaluate the impact of mite treatments on honey quality? Ensure Pure & Stable Yields