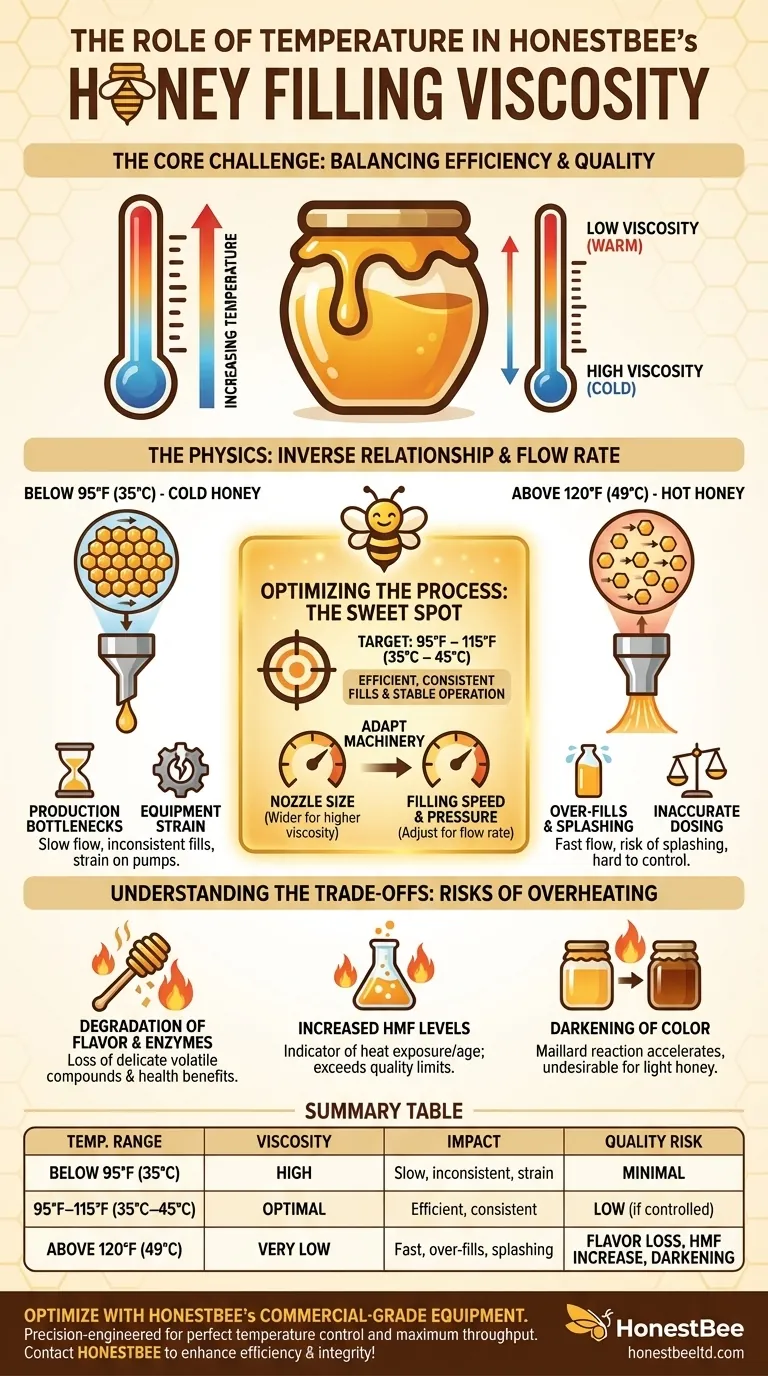

In short, temperature is the primary control lever for honey's viscosity during filling. As honey warms, its viscosity decreases, allowing it to flow more freely and quickly. Conversely, as it cools, its viscosity increases, causing it to become thick and slow-moving. This inverse relationship directly dictates the speed, accuracy, and efficiency of any bottling or packaging operation.

The core challenge of honey filling is not simply making the honey flow, but managing a precise balance. You must heat the honey enough to achieve an efficient and consistent fill, without heating it so much that you damage its delicate flavor, color, and chemical composition.

The Physics of Honey Viscosity

Understanding how temperature affects honey is the first step toward controlling your process. It's a matter of managing molecular energy to achieve a practical outcome.

Temperature's Inverse Relationship

At a molecular level, honey is a super-saturated solution of sugars. When cold, these sugar molecules are tightly packed and move sluggishly, creating high internal friction, or viscosity.

Applying gentle heat gives these molecules more energy. They begin to move faster and slide past one another with less resistance, causing the overall viscosity of the honey to drop.

The Impact on Flow Rate

This change in viscosity has a direct and immediate impact on your filling equipment.

- Cold, viscous honey flows slowly. This can lead to production bottlenecks, inconsistent fill volumes (under-fills), and strain on pumps and motors.

- Warm, fluid honey flows quickly. While this can increase throughput, it also raises the risk of over-fills, splashing, and inaccurate dosing if the machinery is not adjusted accordingly.

Beyond Temperature: Other Key Factors

While temperature is the most dynamic variable, two other factors play a role in honey's baseline viscosity.

- Moisture Content: Honey with lower moisture content is naturally more viscous than honey with higher moisture content.

- Floral Source: The specific type of nectar the bees gathered affects the sugar profile. For example, Tupelo honey is known to be less viscous than a wildflower or buckwheat honey, even at the same temperature.

Optimizing Your Filling Process

The goal is to find the "sweet spot"—a temperature that makes the honey workable without compromising its quality. This requires a systems-based approach.

Establishing a Target Temperature

There is no single universal temperature, but a common working range is 95°F to 115°F (35°C to 45°C).

The exact target depends on your honey's natural viscosity and your equipment's capabilities. The key is to choose a temperature and keep it stable throughout the entire production run.

Adapting Your Filling Machinery

Once you've stabilized the honey's temperature, you must calibrate your machinery to match its flow characteristics.

- Nozzle Size: More viscous honey may require a wider nozzle to prevent clogging and ensure a smooth, consistent stream.

- Filling Speed & Pressure: You must adjust the pump speed or piston pressure. A faster flow rate from warmer honey will require a shorter fill cycle to hit the target weight or volume accurately.

Understanding the Trade-offs: The Risk of Overheating

Applying too much heat is far more damaging than using too little. Aggressive or prolonged heating can irreversibly degrade the quality of your product.

Degradation of Flavor and Enzymes

Honey contains delicate enzymes and volatile aromatic compounds that give it its unique flavor and health benefits. Temperatures above 120°F (49°C) can begin to break down these components, resulting in a less flavorful, one-dimensional product.

Increased HMF Levels

Heating causes a chemical reaction that increases levels of Hydroxymethylfurfural (HMF). While not harmful, HMF is a key indicator of heat exposure or age. Many quality standards and international markets have strict limits on HMF, and exceeding them can render your honey unsellable as a premium product.

Darkening of Color

Heat accelerates the Maillard reaction between sugars and amino acids, which can cause the honey to darken. This is especially problematic for light-colored honeys like acacia or clover, where customers expect a pale, golden hue.

Making the Right Choice for Your Goal

Your ideal temperature strategy depends on your primary operational priority.

- If your primary focus is maximizing throughput: You will need to find the highest possible temperature that allows for rapid filling without pushing HMF levels or flavor degradation beyond your quality threshold.

- If your primary focus is preserving artisanal quality: Use the lowest possible temperature that makes the honey workable, even if it slows down the bottling process. This is critical for "raw" honey producers.

- If your primary focus is ensuring fill accuracy: The most important factor is stability. Maintaining a consistent temperature throughout the tank and over the entire run is more critical than the specific number itself.

Mastering temperature control is mastering your honey filling operation.

Summary Table:

| Temperature Range | Honey Viscosity | Impact on Filling Process | Quality Risk |

|---|---|---|---|

| Below 95°F (35°C) | High | Slow flow, inconsistent fills, equipment strain | Minimal quality loss |

| 95°F–115°F (35°C–45°C) | Optimal | Efficient, consistent fills, stable operation | Low risk if controlled |

| Above 120°F (49°C) | Very Low | Fast flow, risk of over-fills, splashing | Flavor loss, HMF increase, color darkening |

Optimize your honey filling operation with HONESTBEE's commercial-grade equipment. We supply durable, precision-engineered beekeeping supplies and bottling solutions to commercial apiaries and distributors. Our wholesale-focused operations ensure you get reliable tools to maintain perfect temperature control, protect honey quality, and maximize throughput. Contact HONESTBEE today to discuss how our equipment can enhance your efficiency and product integrity!

Visual Guide

Related Products

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Honey Press Wax Press with Tank

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What are the best practices for achieving professional-looking honey bottling results? Master the Art of Honey Packaging

- How do industrial honey-filling machines boost apitourism value? Transform Your Production into a Premium Experience

- How do industrial honey filling machines protect the biological activity of honey? Ensure Nutritional Integrity

- What are the primary benefits of utilizing automated honey-filling machines? Scale Your Commercial Honey Processing

- What are the core advantages of automated hive and honey-filling machines? Scale Your Apiary with Industrial Precision

- What key factors should be considered when choosing a honey-filling machine? Optimize Your Production Line

- How do precision pH meters and automatic titration systems ensure honey quality before automatic filling?

- How does the use of professional automated honey-filling machines benefit urban honey production? Scale Your Apiary