In professional honey processing, vacuum technology serves a single, critical function: to gently remove excess water from raw honey. This process concentrates the honey, prevents it from fermenting, and preserves its natural quality, ensuring it meets industry standards for consistency and long-term shelf stability.

The core challenge in honey processing is reducing water content without damaging the honey's delicate enzymes and flavors with heat. Vacuum technology is the solution, as it lowers the boiling point of water, allowing for its removal at low temperatures.

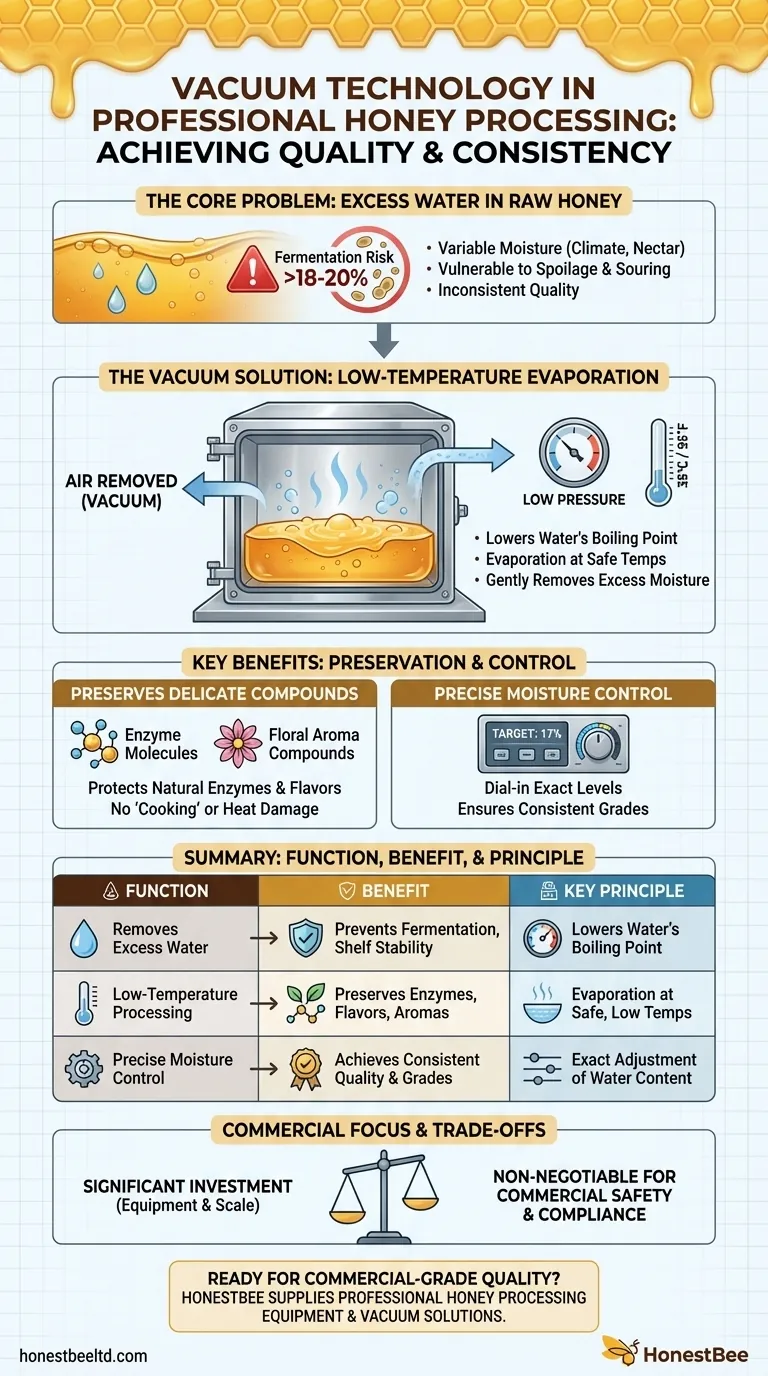

The Core Problem: Excess Water in Raw Honey

To understand the need for this technology, you must first understand the problem it solves. Raw honey, straight from the hive, is not always a finished product.

Why Water Content Varies

The moisture level in raw honey can fluctuate significantly. This is influenced by factors like the local climate, the type of nectar the bees collected, and whether the honey was harvested before the bees had a chance to dehydrate it themselves.

The Fermentation Risk

Honey with a water content above approximately 18-20% is vulnerable to spoilage. Naturally occurring yeasts can begin to ferment the sugars, turning the honey sour and alcoholic, rendering it unsellable.

Impact on Quality and Consistency

Professional standards and official grades for honey have strict limits on water content. To create a consistent, shelf-stable product that meets these requirements, processors must be able to precisely control the final moisture level.

How Vacuum Processing Solves the Problem

Simply heating honey to evaporate water would be destructive. It would essentially cook the product, destroying its beneficial enzymes and delicate aromas. Vacuum processing is a far more elegant solution.

Lowering Water's Boiling Point

The core principle is simple physics. By placing the honey in a sealed chamber and removing the air (creating a vacuum), the atmospheric pressure is drastically lowered.

This reduction in pressure lowers the boiling point of water. Water that would normally boil at 100°C (212°F) can be made to evaporate at much lower, safer temperatures, often close to room temperature.

Preserving Delicate Compounds

This low-temperature evaporation is the key advantage. It allows processors to remove excess water without "cooking" the honey.

Crucial enzymes, subtle flavors, and volatile aromatic compounds—the very things that define a high-quality honey—are preserved.

Achieving Precise Control

Vacuum systems give processors precise control over the final product. They can dial in the exact moisture percentage needed to meet a specific grade or achieve a desired thickness, ensuring every batch is perfectly consistent.

Understanding the Trade-offs

While highly effective, vacuum technology is a specific tool with its own context and limitations.

Equipment Cost and Scale

Vacuum drying equipment represents a significant capital investment. It is a technology primarily suited for commercial, large-scale honey processors, not hobbyist beekeepers.

Not a Fix for Poor Harvesting

This process is meant for standardization and quality control, not as a remedy for harvesting fundamentally unripe honey. The best final product always starts with honey that was properly ripened in the hive by the bees.

Making the Right Choice for Your Goal

The use of this technology is directly tied to the producer's final objective.

- If your primary focus is large-scale commercial production: Vacuum processing is a non-negotiable tool for ensuring product safety, consistency, and compliance with industry grade standards.

- If your primary focus is preserving artisanal quality: Low-temperature vacuum drying is the ideal method for maintaining the honey's unique terroir, flavor profile, and beneficial enzymes.

- If you are a small-scale beekeeper: Your best strategy is to rely on the bees themselves by harvesting honey only after they have "capped" the cells with wax, their natural signal that it has reached the right moisture content.

Ultimately, vacuum technology allows honey's natural excellence to be captured and preserved on a commercial scale.

Summary Table:

| Function | Benefit | Key Principle |

|---|---|---|

| Removes Excess Water | Prevents fermentation, ensures shelf stability | Lowers water's boiling point under vacuum |

| Low-Temperature Processing | Preserves natural enzymes, flavors, and aromas | Evaporation occurs at safe, low temperatures |

| Precise Moisture Control | Achieves consistent product quality and industry grades | Allows for exact adjustment of final water content |

Ready to achieve commercial-grade honey quality and consistency?

HONESTBEE supplies professional-grade honey processing equipment, including vacuum technology solutions, to commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations provide the reliable tools you need to preserve honey's natural excellence on a large scale.

Contact HONESTBEE today to discuss how our equipment can enhance your processing efficiency and product quality.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- Can you dehumidify honey? A Beekeeper's Guide to Preventing Fermentation

- What are some methods to prevent fermentation in high-moisture honey? Protect Your Honey's Quality and Value

- How does temperature regulation help in managing honey moisture content? Prevent Fermentation & Ensure Quality

- What is the recommended drying temperature and moisture content for honey? Preserve Quality & Prevent Fermentation

- How much honey can a honey dryer process and by what percentage does it reduce moisture? Optimize Your Honey Production