The most critical considerations for feeding bees in the fall are the timing of the feed, the strategic goal of the feeding (building population vs. adding weight), and the selection of an appropriate feeder that minimizes risk and disruption to the colony. Completing all feeding early in the season is paramount, allowing the bees sufficient warm weather to process and store the feed properly.

Fall feeding is not simply about adding sugar; it's a strategic intervention to ensure your colony has both enough properly-cured winter food and a large population of young 'winter bees' to survive the cold months ahead.

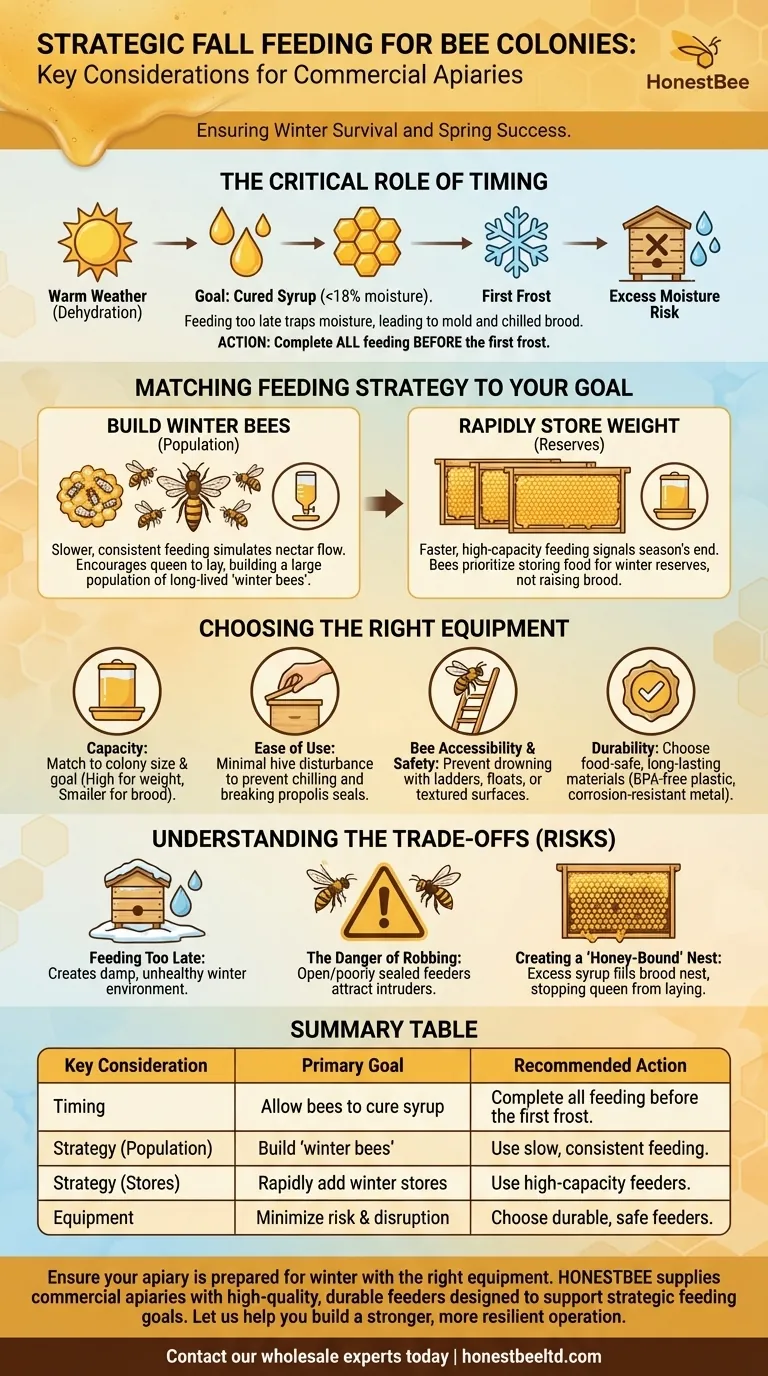

The Critical Role of Timing

Proper timing is the foundation of successful fall feeding. Acting too late in the season can do more harm than good by introducing excess moisture into the hive just as cold weather arrives.

Why Early Feeding is Non-Negotiable

Bees treat sugar syrup much like they treat nectar. They must dehydrate it to a moisture content below 18% to prevent fermentation and spoilage.

This process of evaporation requires warm, dry daytime temperatures. Feeding too late in the season means the bees cannot effectively remove this excess moisture before clustering for warmth.

The Dangers of Excess Moisture

A hive with high internal moisture during winter is a dangerous environment. It can lead to moldy frames, chilled brood, and increased stress on the colony, making them more susceptible to disease.

Matching Feeding Strategy to Your Goal

Not all fall feeding is the same. Your approach should be dictated by the specific needs of your colony, whether that's increasing the number of bees or simply topping up their food reserves.

The Goal: Building Winter Bees

To ensure a strong population for winter, you may need to encourage the queen to continue laying eggs late into the season. These "winter bees" are physiologically different and live much longer than summer bees.

A slower, more consistent feeding pace better simulates a natural nectar flow. This signals to the colony that resources are still available, prompting the queen to continue laying and bolstering the winter population.

The Goal: Rapidly Storing Weight

If a colony already has a robust population but is light on stored food, the goal shifts to getting as much feed into the hive as possible.

In this scenario, a faster feeding method using high-capacity feeders is more effective. This tells the bees that the season is ending and their priority should be storing food, not raising more brood.

Choosing the Right Equipment

The feeder you choose directly impacts the efficiency of your feeding and the safety of your bees. The right equipment minimizes your disruption and protects the colony.

Feeder Capacity

High-capacity feeders are ideal for large, strong colonies that need to store a significant amount of food quickly. Smaller capacity feeders are suitable for smaller colonies or for the slower feeding method aimed at raising brood.

Ease of Use

Select a feeder that is easy to refill with minimal disturbance to the hive. Opening the hive repeatedly in cool weather can chill the bees and break the propolis seal they have worked hard to create.

Bee Accessibility and Safety

The best feeders provide easy access to the food while preventing bees from drowning. Look for designs that include ladders, floats, or textured surfaces that allow bees to climb out if they fall in.

Durability

Choose feeders made from durable, food-safe materials like BPA-free plastic or corrosion-resistant metal. This ensures they can be cleaned effectively and reused for many seasons.

Understanding the Trade-offs

While essential, fall feeding carries inherent risks that must be managed carefully to avoid creating new problems for your colony.

The Risk of Feeding Too Late

This is the most common mistake. As stated, late feeding introduces excess moisture that the bees cannot cure, creating a damp, unhealthy winter environment. All feeding should be concluded before the first frost.

The Danger of Robbing

Open feeding or poorly-sealed feeders can attract bees from other hives, as well as wasps and other insects. This can trigger "robbing," where intruder bees overwhelm a hive to steal its stores, often resulting in the death of the colony.

Creating a "Honey-Bound" Nest

Feeding too much, too quickly can cause the bees to fill the brood nest with syrup. This leaves no room for the queen to lay eggs, effectively shutting down the production of new winter bees.

Making the Right Choice for Your Colony

Ultimately, your fall feeding strategy should be a direct response to the specific condition and needs of each individual hive.

- If your primary focus is building population: Utilize a slower feeding method to encourage the queen to lay and raise more winter bees.

- If your primary focus is adding winter stores quickly: Use a high-capacity, easily accessible feeder to allow the bees to pack on weight before the weather turns cold.

- If you manage multiple hives with different needs: Assess each colony individually and tailor your timing and feeding pace accordingly.

Proper fall feeding is the single most important investment you can make in your colony's winter survival and subsequent spring success.

Summary Table:

| Key Consideration | Primary Goal | Recommended Action |

|---|---|---|

| Timing | Allow bees to cure syrup | Complete all feeding before the first frost. |

| Strategy | Build population of 'winter bees' | Use slow, consistent feeding to simulate a nectar flow. |

| Strategy | Rapidly add winter stores | Use high-capacity feeders for fast, heavy feeding. |

| Equipment | Minimize risk & disruption | Choose durable, high-capacity feeders that prevent drowning. |

Ensure your apiary is prepared for winter with the right equipment.

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable feeders and essential beekeeping supplies through our wholesale-focused operations. Our products are designed to support your strategic feeding goals, minimize hive disruption, and maximize colony health.

Let us help you build a stronger, more resilient operation. Contact our wholesale experts today to discuss your needs and secure the right supplies for a successful season.

Visual Guide

Related Products

- Automatic Pneumatic Bee Frame Machine for Eyelet Insertion

- Slatted Porter Style Bee Escape for Rapid Hive Clearing

- Mini Desktop Bee Hive Frame Forming Making Machine

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What are the general types of equipment available for beekeeping? Essential Gear for Success

- Why is the implementation of integrated sets of improved beekeeping machinery critical for modern apiculture? Scale Up

- What is the importance of providing comprehensive beekeeping tools? Build a Professional Hardware Supply System

- How does the distinction between naturally distributed plants and exotic introduced plants affect long-term investment strategies for beekeeping machinery and equipment?

- How does a bee frame making machine work? A Guide to Automated Metal Frame Production