Once you've extracted your honey, the leftover wax cappings are a valuable secondary harvest, not waste. The essential process involves separating the remaining honey from the wax, then melting, filtering, and solidifying the clean beeswax into usable blocks. This turns a messy byproduct into a resource for beekeeping, crafting, and more.

At its core, processing wax cappings is about transforming a raw, honey-soaked material into two distinct, valuable products: reclaimed honey and clean, pure beeswax. The method you choose simply determines the efficiency and effort required for this separation.

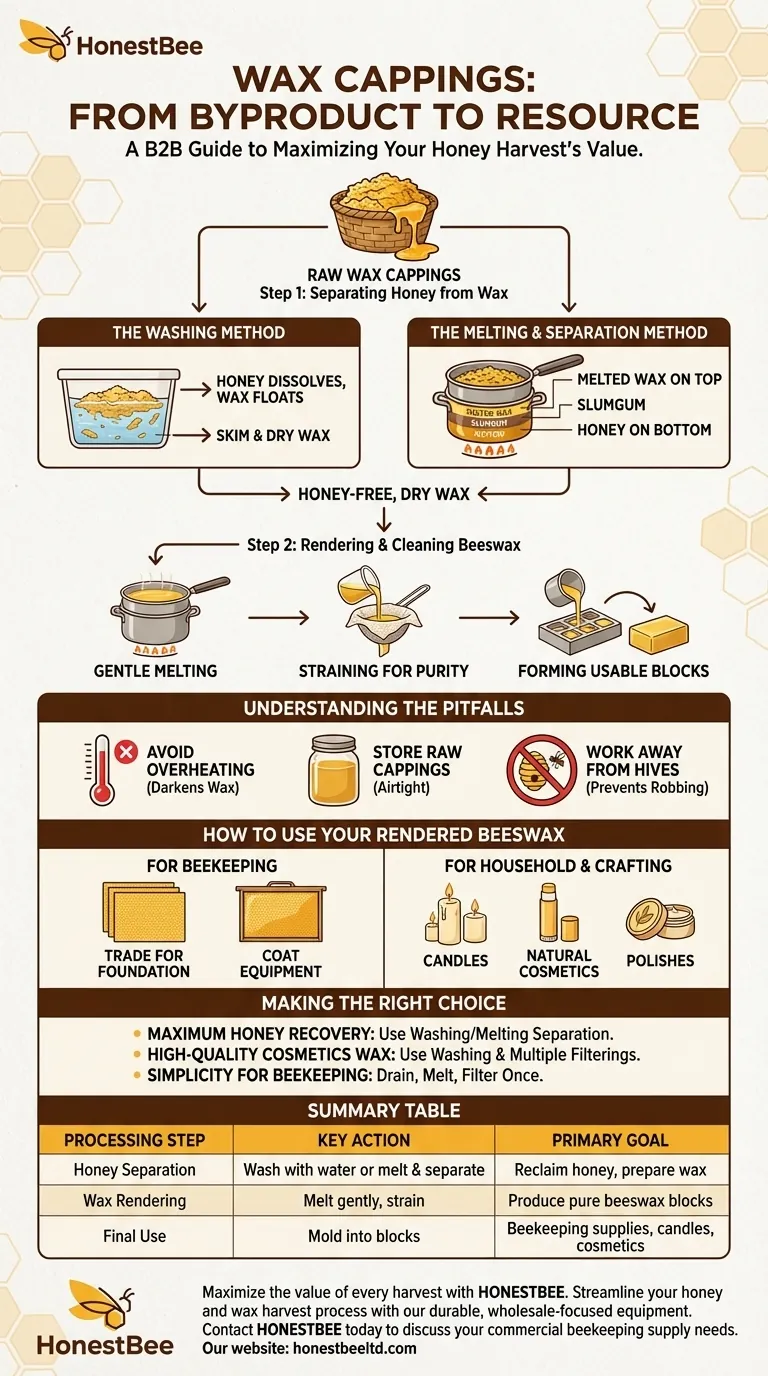

Step 1: Separating Honey from the Wax

Your first task is to remove the significant amount of honey that still clings to and is trapped within the wax cappings. You have two primary methods for this.

The Washing Method

This technique uses water to dissolve the remaining honey. Place the cappings in a container and cover them with cool or lukewarm water. Agitate the mixture, then let it sit.

The honey will dissolve into the water, and the wax will float. You can then skim the wax off the top and set it aside to dry completely before you begin the melting process. The resulting honey-water can be used for feeding bees or making mead.

The Melting & Separation Method

This method combines honey separation and the initial melting phase. Place the cappings in a double boiler or a pot set within a larger pot of water.

As you gently heat the mixture, the wax will melt and float to the top, while the heavier honey and other debris will sink to the bottom. Once cooled, you will have a solid layer of wax on top, a layer of honey on the bottom, and a thin, dark layer of impurities (often called "slumgum") in between.

Step 2: Rendering and Cleaning the Beeswax

Once the wax is mostly free of honey and thoroughly dry, the next step is to render it into clean, pure blocks. This process removes the final impurities.

The Melting Process

Using a double boiler is the safest way to melt beeswax. Direct heat can easily scorch the wax, darkening its color and giving it a burnt smell. Heat the water in the bottom pot, allowing the gentle, indirect heat to melt the wax in the top pot.

Straining for Purity

Once the wax is fully melted, you must filter it to remove hive debris, propolis, and any remaining slumgum. Pour the hot liquid wax through several layers of cheesecloth or a finer-mesh paint strainer into a heat-safe mold or container.

For exceptionally clean wax suitable for cosmetics, you may need to repeat the melting and straining process two or three times.

Forming Usable Blocks

Pour the final, filtered liquid wax into molds. Silicone baking molds, bread pans, or simple plastic containers work well. Let the wax cool and harden completely at room temperature. Once solid, you will have clean, stable blocks of beeswax that are easy to store and use.

Understanding the Pitfalls

Processing wax is straightforward, but a few common mistakes can impact the quality of your final product.

Avoid Overheating the Wax

Exposing beeswax to excessive heat will darken its color from a pleasant yellow to a dull brown and can damage its delicate aroma. Always use a double boiler or a temperature-controlled wax melter.

Storing Raw Cappings

If you can't process your cappings immediately, store them in a sealed, airtight container in a cool, dark place. This prevents pests like wax moths from infesting them and protects them from dust and debris.

Work Away From Your Hives

The smell of honey and wax is extremely attractive to bees. To prevent a robbing frenzy and agitated bees, it's best to process your cappings indoors or at a significant distance from your apiary.

How to Use Your Rendered Beeswax

Clean beeswax is a versatile and valuable material with numerous applications.

For Beekeeping

The most common beekeeping use is to trade your clean wax blocks for new beeswax foundation sheets from beekeeping suppliers. You can also use the wax to coat new plastic frames or woodenware, which encourages the bees to accept and build on it more quickly.

For Household and Crafting

Pure beeswax is a premium ingredient for many products. It can be used to make candles, which burn cleaner and longer than paraffin. It is also a key ingredient in natural cosmetics like lip balms, salves, and solid lotions, as well as in recipes for furniture polish.

Making the Right Choice for Your Harvest

How you process your cappings depends on your end goal.

- If your primary focus is maximum honey recovery: Use the washing or melting separation methods to ensure you reclaim every possible drop of honey.

- If your primary focus is high-quality wax for cosmetics: Use the washing method for separation, followed by multiple rounds of slow, low-heat melting and fine filtering.

- If your primary focus is simplicity for beekeeping use: Simply letting the cappings drain for an extended period, then melting and filtering them once is sufficient to create wax for coating equipment.

By properly processing your wax cappings, you honor the work of your bees and turn a simple byproduct into a valuable resource.

Summary Table:

| Processing Step | Key Action | Primary Goal |

|---|---|---|

| Honey Separation | Wash with water or melt & separate | Reclaim honey, prepare wax for rendering |

| Wax Rendering | Melt gently with a double boiler, strain through cheesecloth | Produce clean, pure beeswax blocks |

| Final Use | Mold into blocks for storage or immediate application | Create beekeeping supplies, candles, or cosmetics |

Maximize the value of every harvest with HONESTBEE.

As a commercial apiary or beekeeping equipment distributor, efficiently processing wax cappings is crucial for maximizing your operation's profitability. The clean beeswax you produce can be traded for foundation sheets or used to create premium value-added products.

HONESTBEE supplies the durable, wholesale-focused beekeeping equipment you need to streamline your entire honey and wax harvest process—from extraction to rendering. Let us help you turn every byproduct into profit.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- What is the recommended maximum temperature setting for processing beeswax in the electric double boiler? Melt Wax Safely at 80°C

- What are wax melters used for? Unlock Efficient Wax Processing for Your Business

- What is the temperature performance of a solar wax melter? Optimize Your Yield with Passive Solar Heat

- How does a solar extractor function in the context of wax processing? Efficient Solar Rendering for Pure Beeswax

- Why is high-precision constant temperature heating equipment used for beeswax? Ensure Molecular Homogenization

- What should you do after the beeswax has completely melted? Act Quickly to Ensure a Perfect Pour

- How does a solar wax melter facilitate the rendering of beeswax? Efficient, Passive Sun-Powered Purification

- Why is it important not to boil the water during the hot water extraction of beeswax? Preserve Purity and Color